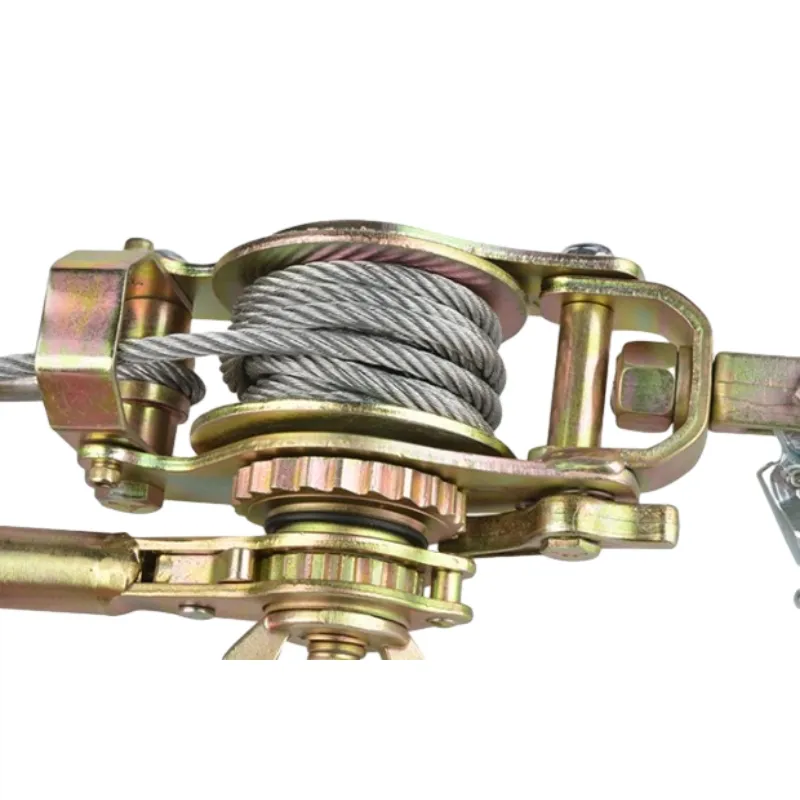

- The working principle of the ratchet tensioner is based on the anti-reverse action of the pawl.

- During use, the steel wire rope or galvanized iron wire on the tensioner is first loosened and fixed on the cross-arm.

- Then, a wire clamp is used to grip the conductor. Next, by turning a special wrench, the pawl gradually winds the steel wire rope or galvanized iron wire around the ratchet drum, thereby tightening the conductor.

- After tightening, the conductor is fixed on the insulator, and then the pawl and wire clamp are released to complete the tightening

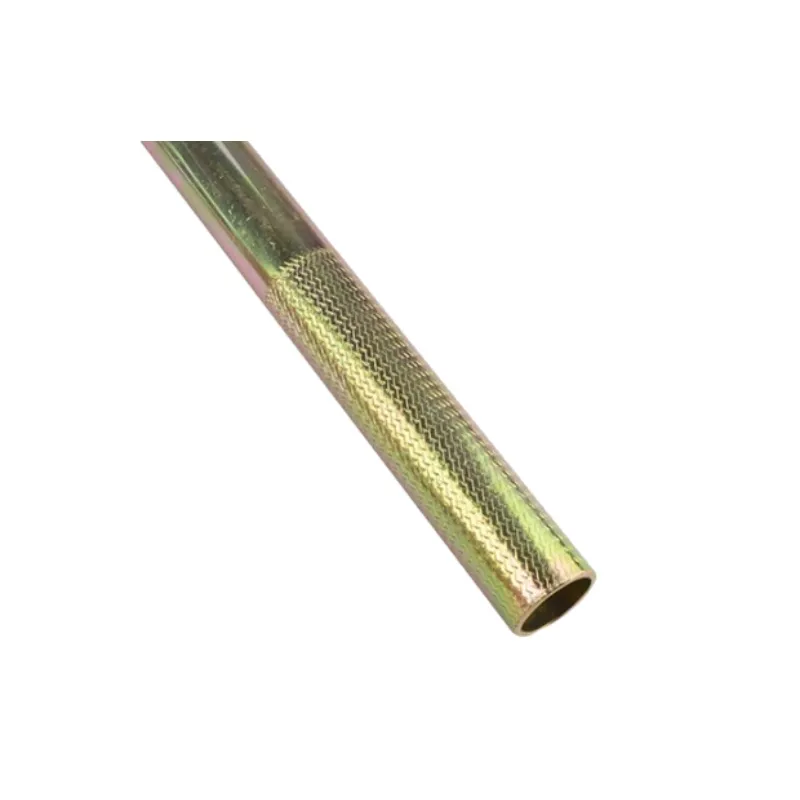

- 1. Thread coil wire rope

- Anti-twist type thickened steel wire rope, without loose rope and burr. 360°crimping does not fall off, solid and durable.

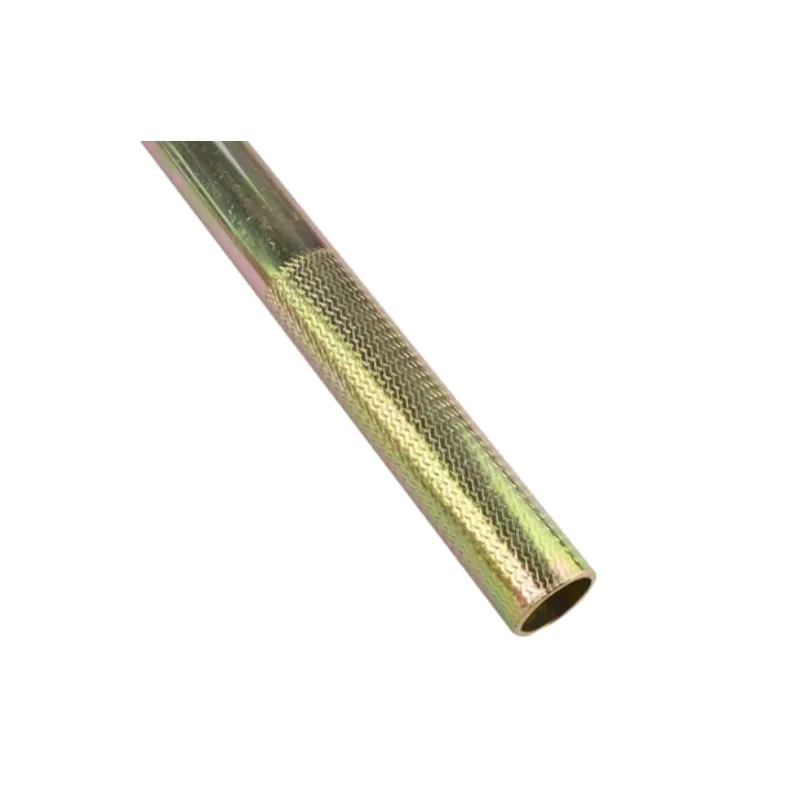

- 2. Anti-skid handle

- Anti-slip thread design, use the fitting handle for a long time, 360 rotation control clamp can rotate backwards, and can be loosened in both directions.

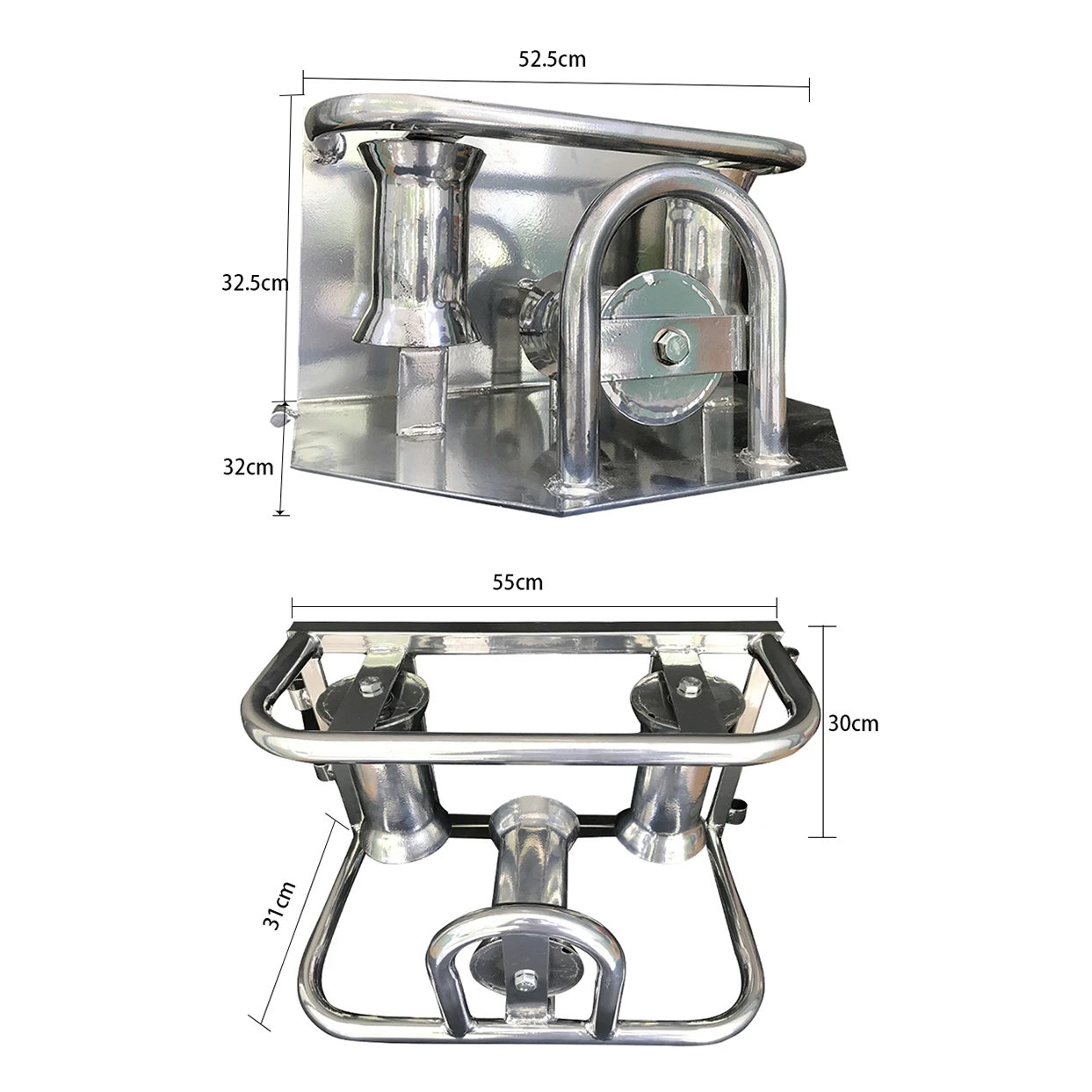

|

Model |

Pulling force(KN) |

Og'irligi (kg) |

|

JXRS-05 |

5 |

2.6 |

|

JXRS-10 |

10 |

3.2 |

|

JXRS-15 |

15 |

4.0 |

|

JXRS-20 |

20 |

4.3 |

|

JXRS-30 |

30 |

6.2 |

|

Material |

High-strength alloy steel |

|

|

Function |

Fixation/traction/lifting |

|

|

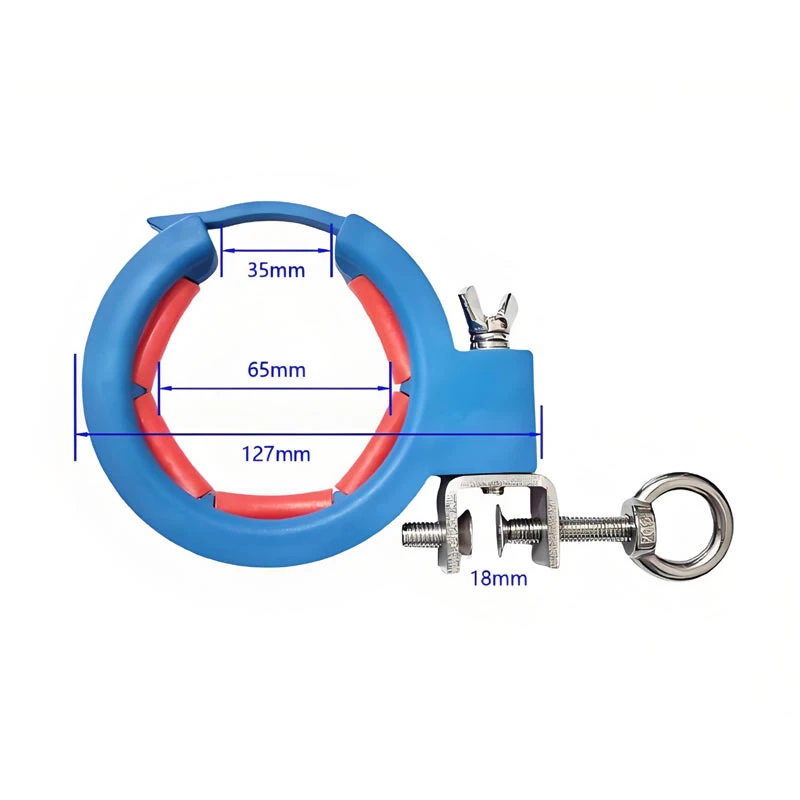

accessory products |

Used in conjunction with cable clamps |

|

Choosing the Right Ratchet Cable Puller / Cable Tightener

Selecting the appropriate Ratchet Cable Puller / Cable Tightener is crucial for achieving safe and effective cable installation. There are several factors to consider when choosing the right model for your project.

First, consider load capacity. Different projects require different pulling forces. Heavy-duty industrial or power line projects may need high-capacity pullers capable of handling several tons, while smaller tasks like fencing or telecommunication wiring can use lighter-duty models. Ensuring the puller’s rated capacity meets your requirements is critical for safety and efficiency.

Next, examine build quality and materials. High-quality Ratchet Cable Puller / Cable Tightener tools are made from forged steel or aluminum alloy, providing durability, strength, and corrosion resistance. The ratchet mechanism should be smooth and reliable, allowing for precise incremental tensioning without slipping or binding.

Portability and ergonomics are also important. Lightweight, compact designs with comfortable grips reduce operator fatigue and make the tool easier to transport between worksites. Some models feature adjustable hooks or clamps for versatile cable handling, further enhancing convenience.

Finally, look for safety features. Many pullers include locking mechanisms, non-slip grips, or safety latches to prevent accidental release under tension. Using a well-designed Ratchet Cable Puller / Cable Tightener minimizes risks while ensuring consistent cable alignment and tension.

By choosing the right Ratchet Cable Puller / Cable Tightener, professionals can complete cable installation and maintenance projects more efficiently, safely, and with better overall results.

Ratchet Cable Puller / Cable Tightener for Outdoor Power Line Projects

When working on outdoor power line installations or telecommunication lines, controlling and tensioning cables is a critical task. The Ratchet Cable Puller / Cable Tightener provides a reliable solution for lifting, stretching, and securing cables under high tension. Its ratchet mechanism allows operators to gradually apply force, ensuring cables are properly aligned without risk of snapping or slippage.

Constructed from high-strength steel with corrosion-resistant coatings, the Ratchet Cable Puller / Cable Tightener is durable enough to withstand harsh weather conditions and repeated heavy-duty use. It comes with hooks or clamps to secure cables safely, while the ratchet system provides mechanical advantage, allowing one operator to handle tasks that would otherwise require multiple workers.

This tool is particularly valuable in outdoor projects where cable lengths are long and precision is crucial. Using a Ratchet Cable Puller / Cable Tightener ensures consistent tension along the entire cable run, preventing sagging or uneven alignment. Additionally, the controlled ratchet action reduces labor fatigue and improves overall safety on the worksite.

By integrating the Ratchet Cable Puller / Cable Tightener into outdoor cable projects, crews can achieve faster, safer, and more efficient installations, making it an indispensable tool for line workers, electricians, and utility companies.

Maintenance Tips for Your Ratchet Cable Puller / Cable Tightener

A Ratchet Cable Puller / Cable Tightener is a precision tool that can last for years if properly maintained. Regular maintenance not only extends its lifespan but also ensures safe and efficient operation during cable installation and tensioning tasks.

After each use, clean the tool to remove dirt, grease, or debris that could interfere with the ratchet mechanism. Lubricate moving parts and the ratchet gear with light oil to prevent rust and maintain smooth operation. A well-lubricated Ratchet Cable Puller / Cable Tightener ensures precise incremental pulling and reduces the effort required by the operator.

Inspect the hooks, clamps, and ratchet system regularly for signs of wear or damage. Any deformations, cracks, or worn teeth should be addressed immediately, as they could compromise safety or performance. Using a damaged Ratchet Cable Puller / Cable Tightener could lead to cable slippage or accidents on site.

Additionally, store the tool in a dry, secure location and avoid exposing it to excessive moisture or harsh chemicals. Ergonomic handles and safety locks should be checked regularly to maintain operator comfort and secure operation.

By following these maintenance practices, a Ratchet Cable Puller / Cable Tightener remains a dependable tool, ensuring clean, safe, and efficient cable pulling and tensioning for every project.