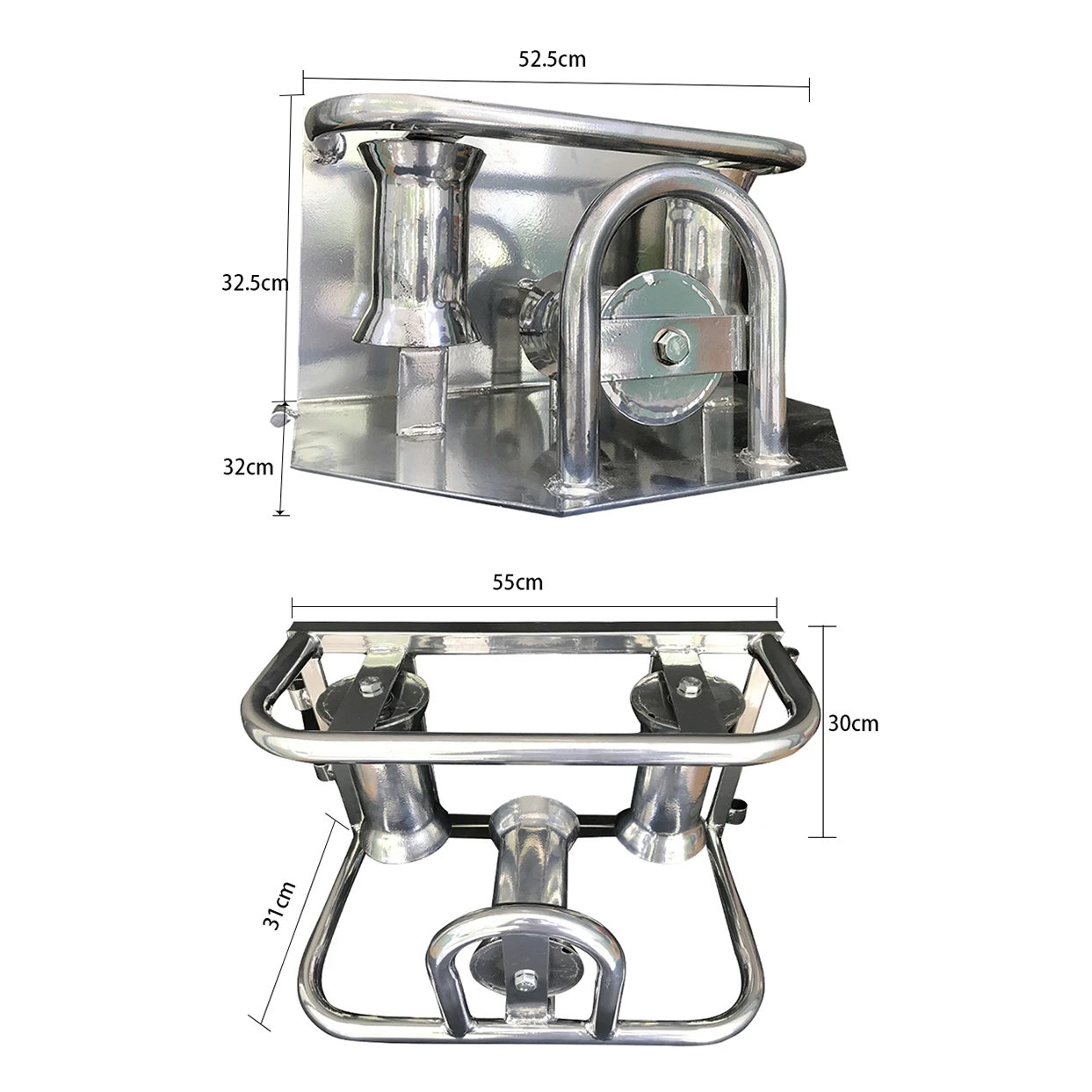

- 1. Flexibility: It has a universal rotation function that can adapt to pulling needs in different directions and angles.Strong Load Capacity: It can withstand a large pulling force, ensuring the stability and safety of the cable during pulling.

- 2. Wear-resistant and Corrosion-resistant: Made of high-quality materials, it has good wear resistance and corrosion resistance, allowing for long-term use in harsh environments.

- 3. It is suitable for connecting the wire rope and the net sleeve connecting the wire rope in the transmission line and releasing the twisting force of the wire rope.

- 4. All stainless steel body construction allows smooth rotation, even under full load

- 5. Clevis pins are a in shoulder bolt in style, so load on both sides of clevis is taken on the shoulder, not the thread.

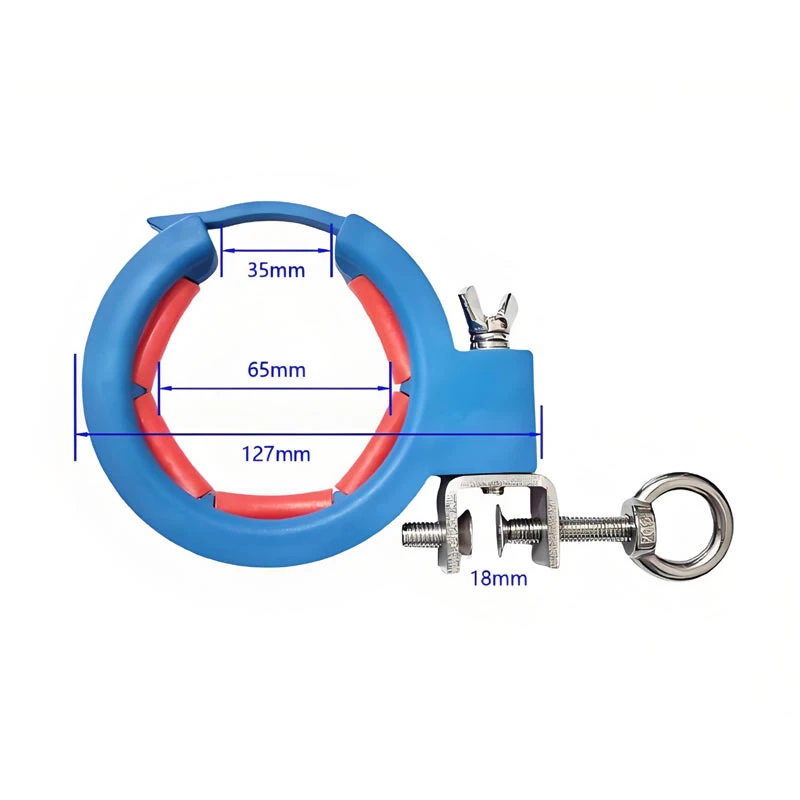

|

Items No. |

Pulling capacity |

Length (MM) |

Outer diameter (MM) |

Groove width (MM) |

Og'irligi (kg) |

|

XZLJ-1 |

1T |

105 |

30 |

13 |

0.4 |

|

XZLJ-2 |

3T |

140 |

37 |

16 |

0.65 |

|

XZLJ-3 |

5T |

157 |

40 |

18 |

1.5 |

|

XZLJ-4 |

8T |

220 |

56 |

25 |

2.4 |

- 1. When purchasing a cable pulling swivel, please ensure that you select a model that meets the cable specifications and pulling requirements.

- 2. Follow the product manual and operating procedures during installation and use to ensure safe operation.

How to Choose the Right Cable Pulling Swivel for Your Application

When it comes to electrical or communication cable installation, using the right cable pulling swivel is crucial for ensuring both efficiency and safety. These small yet vital components prevent cable twisting and kinking during pulling operations, significantly reducing the risk of damage. Selecting the proper swivel depends on several key factors, including cable size, load requirements, and environmental conditions. Understanding these factors will help you choose the ideal cable pulling swivel for your project.

1.Understand the Function of Cable Pulling Swivels

A cable pulling swivel serves as a rotating connection between the pulling line and the cable. Its main function is to allow free rotation while transmitting the pulling force smoothly. This prevents torsional stress, which can cause cable deformation or internal damage. In applications such as underground cable installation, electrical wiring, or fiber optic deployment, using a quality swivel ensures smooth and secure pulling without compromising cable integrity.

2. Match the Swivel Strength to Your Load

One of the most important criteria when choosing a cable pulling swivel is its rated load capacity. Each swivel is designed to handle a specific amount of pulling force, usually measured in pounds or kilograms. Selecting a swivel with too low a capacity may lead to mechanical failure, while one that is unnecessarily strong can add unnecessary weight and cost. Always verify the pulling tension of your cable and choose a swivel that meets or exceeds the expected load without exceeding the cable’s rated tensile strength.

3. Choose the Right Material for Durability

Cable pulling swivels are typically made from stainless steel, aluminum, or galvanized steel, each offering different benefits. Stainless steel swivels are corrosion-resistant and ideal for marine or outdoor environments. Aluminum swivels are lightweight yet strong, suitable for portable or light-duty applications. Galvanized steel provides a balance between cost and durability, making it a popular choice for general construction use. Selecting the right material ensures the swivel performs reliably even under harsh conditions.

4. Consider Bearing Type and Design

The swivel’s internal bearing design affects both performance and longevity. Ball-bearing swivels provide smoother rotation and are ideal for continuous or heavy-duty use. Plain-bearing swivels, on the other hand, are more affordable and sufficient for short or medium pulls. The choice depends on the frequency and intensity of your cable installation projects.

5. Check Compatibility and Ease of Use

Finally, make sure the cable pulling swivel fits well with your pulling grips, connectors, and other accessories. The swivel should allow for easy attachment and detachment to minimize setup time and maximize productivity on-site. Some modern designs even feature quick-connect mechanisms for added convenience.

Conclusion

Choosing the right cable pulling swivel is essential to ensure a smooth, efficient, and damage-free cable installation process. By considering factors such as load capacity, material, bearing design, and compatibility, you can select a swivel that meets your specific application needs. Investing in high-quality swivels not only enhances job efficiency but also protects your cables and equipment, saving time and costs in the long run.

Maintenance Tips for Extending the Life of Cable Pulling Swivels

A cable pulling swivel plays a vital role in cable installation by preventing twisting and damage during pulling operations. These components endure high tension, dirt, and environmental stress, making regular maintenance essential for ensuring performance and longevity. Proper care not only extends the service life of the cable pulling swivel but also enhances safety and reduces operational costs. Below are several practical maintenance tips to help you get the most out of your swivels.

Clean After Every Use

After each cable-pulling operation, it’s crucial to clean the cable pulling swivel thoroughly. Dirt, sand, and debris can enter the swivel’s bearings or joints, causing friction and wear over time. Use a soft brush or compressed air to remove dust, and wipe the surface with a clean, dry cloth. For heavy-duty or outdoor applications, consider rinsing the swivel with mild soap and water to remove stubborn residues. Always ensure it is completely dry before storage to prevent corrosion.

2. Regular Lubrication

Proper lubrication is key to keeping the swivel’s internal bearings running smoothly. Depending on the model and material, apply a suitable industrial-grade lubricant or light machine oil to the moving parts. Lubrication reduces friction, minimizes wear, and helps protect against rust. For ball-bearing swivels, lubrication should be done more frequently, especially after use in wet or dusty environments. Avoid using excessive oil, as it may attract dust and cause buildup inside the mechanism.

3. Inspect for Wear and Damage

Before and after each use, inspect the swivel for signs of wear, such as cracks, corrosion, or loosened components. Pay close attention to the bearing section and attachment points, as these areas endure the most stress. If you notice any deformation, grinding noise, or restricted movement, the swivel should be replaced immediately. Using a damaged swivel can lead to cable failure, equipment damage, or even serious accidents.

4. Store Properly in a Dry Environment

When not in use, store your cable pulling swivels in a dry, clean area away from direct sunlight, moisture, or chemicals. Keeping them in a sealed container or tool bag helps prevent dust accumulation and corrosion. For long-term storage, lightly oil the swivel to maintain its protective coating. Avoid stacking heavy tools on top of it, as excess pressure can damage its structure or bearings.

5. Follow Manufacturer’s Recommendations

Each cable pulling swivel model has specific usage and maintenance guidelines provided by the manufacturer. Always follow these recommendations regarding load limits, lubrication intervals, and cleaning procedures. Using the correct tools and following approved maintenance steps ensures the swivel performs as intended and meets safety standards throughout its service life.

Conclusion

Proper maintenance of your cable pulling swivels not only extends their lifespan but also ensures smoother cable installations and greater job safety. By cleaning after each use, lubricating regularly, inspecting for damage, and storing correctly, you can significantly reduce wear and prevent costly downtime. Treat your swivels as precision tools, and they will deliver consistent, reliable performance for years to come.

Enhancing Safety and Efficiency with Cable Pulling Swivels

In modern cable installation projects, safety and efficiency are top priorities. A cable pulling swivel is a small but essential component that plays a crucial role in achieving both. Designed to connect the pulling line to the cable, the swivel allows smooth rotation during pulling operations, preventing twisting, tangling, and damage. By incorporating high-quality cable pulling swivels into your workflow, you can greatly improve the overall performance and reliability of your cable installation process.

1.Preventing Cable Damage Through Smooth Rotation

One of the main functions of a cable pulling swivel is to prevent cable twisting under tension. During cable installation—especially over long distances or through conduits—torsional stress can cause cables to deform or even break. Swivels with precision bearings allow the cable to rotate freely while maintaining tension, ensuring that the pulling force is evenly distributed. This simple yet effective mechanism minimizes internal conductor strain, protecting the integrity of the cable insulation and extending the cable’s service life.

2. Improving Safety in Cable Installation Operations

Safety is a major concern when dealing with heavy cables, electrical systems, or mechanical pulling equipment. Using a cable pulling swivel significantly reduces the risk of accidents caused by cable recoil or sudden twists. It helps stabilize the pulling system, allowing operators to work with greater confidence and control. In high-tension environments—such as underground electrical installations or telecommunications projects—the swivel serves as a reliable safety link that absorbs stress and prevents equipment overload. This contributes to a safer job site and minimizes the risk of costly downtime.

3. Enhancing Operational Efficiency

Efficiency in cable installation is not only about speed but also about consistency and precision. A well-designed cable pulling swivel ensures smooth motion throughout the pulling process, reducing friction and preventing snags. This allows for faster setup and smoother cable deployment, saving valuable time and labor. Moreover, using the correct swivel eliminates the need for frequent adjustments or cable rework, helping crews complete projects on schedule while maintaining high-quality standards.

4. Durability and Long-Term Performance

Modern cable pulling swivels are engineered from high-strength materials such as stainless steel, aluminum, or galvanized steel. These materials offer excellent resistance to corrosion, wear, and heavy loads, making them suitable for challenging environments like construction sites or outdoor installations. Investing in durable swivels not only reduces replacement costs but also ensures long-term reliability across multiple projects.

5. Choosing Quality for Maximum Results

To fully benefit from improved safety and efficiency, it’s important to select swivels that match your application’s load requirements and working environment. Look for products with precision bearings, secure attachment points, and corrosion-resistant finishes. Quality swivels from trusted manufacturers are rigorously tested to handle high pulling forces and repeated use without failure.

Conclusion

By integrating cable pulling swivels into your cable installation system, you can achieve both enhanced safety and operational efficiency. These small but powerful tools protect cables from twisting, safeguard workers from accidents, and streamline the installation process. Whether you’re working in electrical, construction, or communication industries, investing in high-quality cable pulling swivels is a smart, cost-effective way to improve project performance and reliability.