- The cable pulling socks is an ideal tool for electricians and telecommunication technicians to work;

- The single-strand braided cable socks can automatic adjust the grip, provide anti-skid tension and protect the cable insulation from damage.

- Make a quick and easy job for pulling cable and wire through pipe and conduit etc.

- Complete range of cable socks including single eye, double eye, multi weave, lace up and open ended types for pulling and supporting all types of power, fibre, sub-sea cables and umbilical during installation – cable socks are manufactured from either galvanized steel wire, stainless steel wire.

A range of lattice constructions are available – single weave, double weave, triple weave or multi-weave – to achieve the desired cable pulling strength

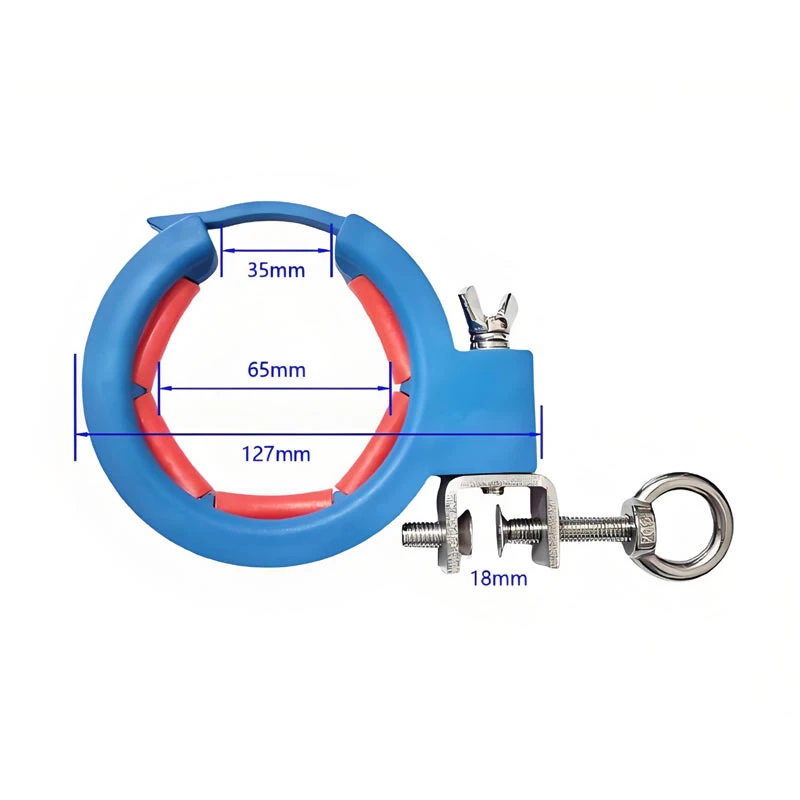

|

Size range(MM) |

Color |

Total length(MM) |

Breaking(KN) |

|

4-6 |

Blue |

220 |

270lb/122kg |

|

6-9 |

Black |

280 |

490lb/222kg |

|

9-12 |

Red |

310 |

700lb/317kg |

|

12-15 |

Yashil |

350 |

800lb/362kg |

|

15-18 |

White |

410 |

890lb/403kg |

|

18-25 |

Sariq |

500 |

1400lb/635kg |

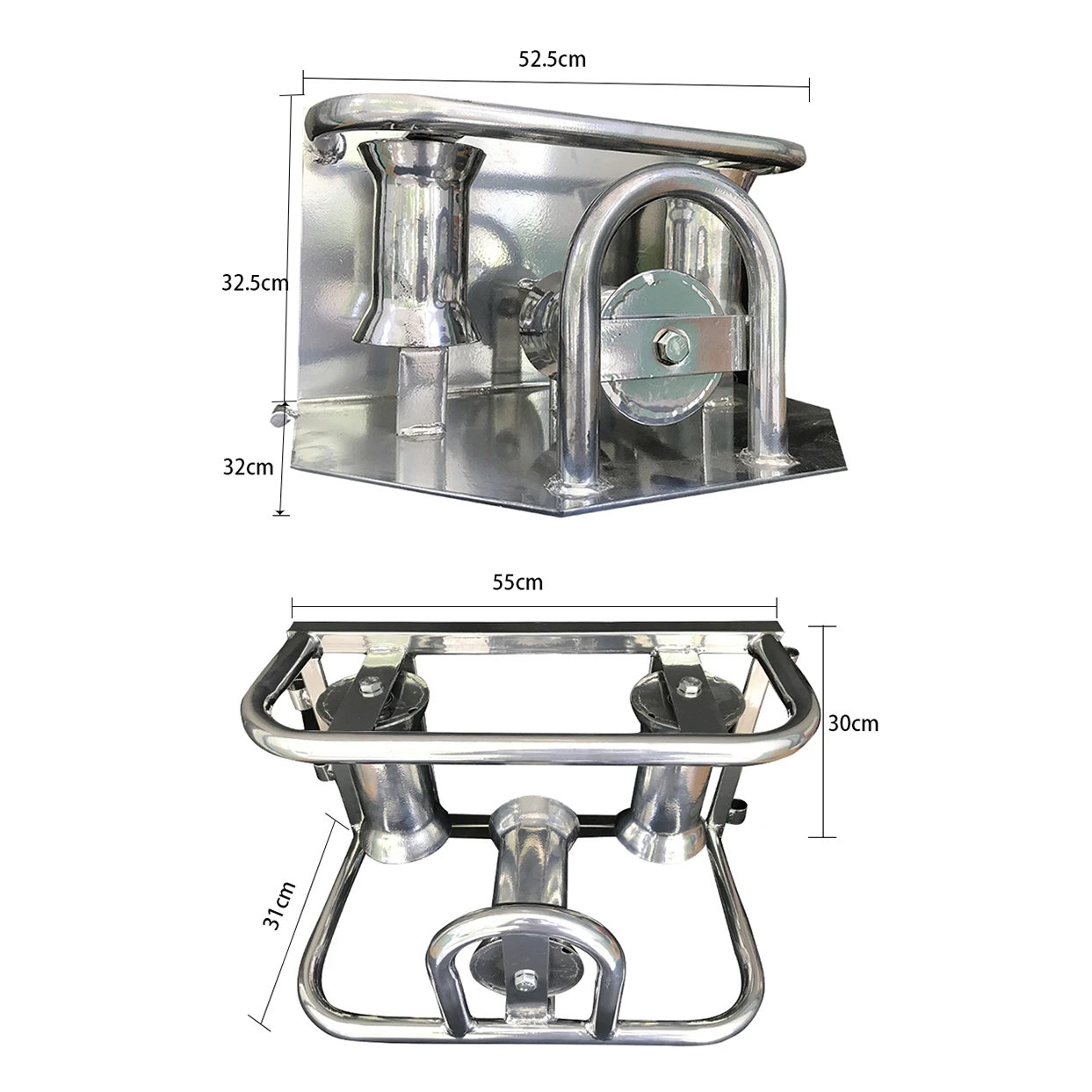

1 Select the correct cable socks for the outside sheath diameter of the cable

2 Widen the lattice at end of cable sock – press end of sock against hard surface to induce expansion on the open end

3 Place the cable sock over the exposed end of the cable,Push sock over the cable

Enhancing Cable Protection and Efficiency with Cable Socks

In modern electrical and telecommunications projects, protecting cables during installation and operation is essential. Cable socks, also known as cable grips or pulling socks, are specialized tools designed to safeguard cables from damage while improving installation efficiency. These versatile devices provide a secure grip on cables, reducing strain, preventing twisting, and minimizing the risk of wear, which is especially important in long-distance or heavy-duty cable installations.

1.Protecting Cables from Damage

One of the primary functions of cable socks is to prevent cable damage during pulling operations. When cables are pulled through conduits, ducts, or trenches, excessive tension, bending, or twisting can compromise the integrity of the cable. Cable socks distribute pulling force evenly along the cable’s surface, reducing localized stress points. This is particularly crucial for fiber optic cables, high-voltage power lines, and other sensitive or expensive cables, where even minor damage can result in system failure or costly repairs.

The mesh design of cable socks allows them to tighten automatically as tension increases, providing a firm yet gentle grip. This feature ensures that the cable remains secure during installation without causing deformation or abrasion to its outer jacket.

2. Improving Installation Efficiency

In addition to protection, cable socks significantly enhance the efficiency of cable installation. Traditional methods, such as manually attaching pulling eyes or clamps, can be time-consuming and less secure. Cable socks simplify the process by quickly slipping over the cable and creating a strong, reliable connection to the pulling line. This reduces setup time, speeds up installation, and allows crews to handle multiple cables simultaneously.

For large-scale projects, such as power distribution networks, telecommunications lines, or industrial wiring, using cable socks minimizes delays and ensures that cables are installed with consistent tension and alignment. The ease of use and secure grip provided by cable socks directly contribute to smoother, more predictable installation outcomes.

3. Versatility for Different Cable Types

Cable socks are available in various sizes and materials to accommodate a wide range of cable types, from small control wires to heavy-duty power cables. Stainless steel or galvanized steel socks offer high strength and corrosion resistance for outdoor or industrial environments, while nylon or synthetic mesh versions are suitable for lighter cables or indoor use. This versatility ensures that every cable type receives appropriate support and protection during installation.

4. Enhancing Safety on the Job Site

By securing cables effectively, cable socks also improve safety for installation crews. Slippage, cable recoil, or sudden tension changes are common hazards when pulling heavy or long cables. Cable socks reduce these risks by maintaining a consistent grip and preventing unexpected movements, allowing operators to work confidently and safely.

Conclusion

Cable socks are essential tools for modern cable installation, combining protection, efficiency, and safety. By distributing pulling forces evenly, minimizing cable stress, and simplifying the installation process, they ensure that cables remain intact and functional throughout their service life. Whether for industrial, commercial, or utility applications, investing in high-quality cable socks enhances both project efficiency and long-term cable reliability.

Proper Use and Maintenance of Cable Socks for Long-Term Performance

Cable socks, also known as cable grips or pulling socks, are essential tools for safely and efficiently installing cables in industrial, commercial, and utility applications. Designed to secure the cable during pulling operations, they prevent twisting, stretching, and damage to the cable’s outer jacket or internal conductors. To ensure long-term performance and reliability, it is crucial to understand their proper use and maintenance.

Correct Installation and Use

Using cable socks correctly begins with selecting the right size and type for the cable being installed. The mesh or braided design should fit snugly around the cable, ensuring even distribution of pulling force. Oversized socks can slip during installation, while undersized socks may cause excessive compression, damaging the cable.

When attaching the sock, ensure that it is properly seated along the cable length. Most cable socks work on a principle where pulling tension tightens the mesh around the cable. Therefore, it is important to attach the pulling line to the looped end securely and check that the cable sock grips firmly before starting the pull. Avoid sharp bends or kinks during the installation, as these can reduce the sock’s effectiveness and put unnecessary stress on the cable.

2. Inspecting for Wear and Damage

Before each use, inspect the cable sock for signs of wear, corrosion, fraying, or broken strands. Steel or metal socks can develop rust, especially in outdoor or humid environments, while synthetic versions may show signs of abrasion or weakening. Using a damaged sock can lead to slippage, reduced grip, or complete failure during installation, potentially harming the cable or causing injury. Replace any worn or damaged socks immediately to maintain safe and reliable performance.

3. Cleaning After Use

After each cable installation, clean the cable sock to remove dirt, dust, and debris. Metal socks can be wiped down with a dry cloth or lightly oiled to prevent corrosion, while synthetic socks should be brushed clean and stored dry. Regular cleaning not only extends the sock’s lifespan but also ensures that it maintains a secure grip in subsequent uses.

4. Proper Storage

Storage plays a critical role in the longevity of cable socks. Keep them in a dry, clean environment, away from direct sunlight, moisture, or chemicals that could degrade the material. Hanging metal socks or coiling synthetic ones prevents deformation and tangling, making them easier to deploy during future installations. Avoid stacking heavy objects on stored socks, as this can damage the mesh structure.

5. Training and Safe Handling

To maximize the performance and lifespan of cable socks, ensure that personnel are trained in their proper handling and usage. Misuse, such as overloading the sock beyond its rated capacity or using it with incompatible cables, can result in accidents or equipment damage. Following manufacturer guidelines and safety protocols guarantees reliable operation and prolongs the sock’s service life.

Conclusion

Proper use and maintenance of cable socks are essential for ensuring long-term performance, safety, and efficiency during cable installations. By selecting the correct size, inspecting regularly, cleaning and storing properly, and training personnel on safe handling, operators can maximize the lifespan of these indispensable tools. Well-maintained cable socks not only protect cables but also streamline installation projects, reducing downtime and maintenance costs while ensuring consistent, reliable results.

The Function and Benefits of Cable Socks in Cable Installation

In modern cable installation projects, especially those involving power lines, telecommunications, or industrial systems, protecting cables during handling and installation is essential. Cable socks, also known as cable grips or pulling socks, are specialized tools designed to secure cables while they are being pulled through conduits, ducts, or trenches. These devices provide both protection and efficiency, making them indispensable in professional cable installation.

1.Understanding the Function of Cable Socks

The primary function of a cable sock is to provide a secure grip on a cable during pulling operations. It consists of a mesh or braided structure that slips over the end of the cable, tightening as tension is applied. This design allows the pulling force to be evenly distributed along the cable, preventing localized stress points that can damage the cable jacket or internal conductors.

By maintaining a stable connection between the cable and the pulling line, cable socks prevent twisting, kinking, and stretching. This is particularly important for delicate or high-value cables, such as fiber optic or high-voltage power lines, where even minor damage can compromise performance or safety.

2. Key Benefits of Using Cable Socks

Using cable socks in installation provides multiple advantages:

Enhanced Cable Protection: The mesh grip reduces the risk of abrasion, deformation, or internal damage, extending the cable’s lifespan and maintaining its functionality.

Improved Installation Efficiency: Cable socks allow for quick attachment to the cable and a secure connection to the pulling line, speeding up installation and reducing manual handling.

Versatility Across Cable Types: Available in various sizes and materials, cable socks can accommodate a wide range of cables—from small control wires to heavy-duty industrial power cables.

Safety for Installation Crews: By preventing slippage or unexpected cable movement, cable socks reduce the risk of accidents during pulling operations.

Cost Savings: Protecting cables from damage during installation reduces repair costs and downtime, making cable socks a cost-effective solution.

3. Material and Design Considerations

Cable socks are made from materials such as stainless steel, galvanized steel, or synthetic fibers, depending on the application. Metal socks offer high strength and corrosion resistance, ideal for outdoor or industrial environments. Synthetic socks are lightweight and flexible, suitable for indoor or temporary installations.

The design of the cable sock—whether braided or woven—affects its grip strength and adaptability to different cable diameters. High-quality socks feature reinforced loops or attachment points to ensure a secure connection to the pulling line, further enhancing safety and reliability.

4. Applications in Cable Installation

Cable socks are widely used in industries such as power distribution, telecommunications, construction, and manufacturing. They are essential for pulling long cable runs through conduits, ducts, or underground tunnels. In addition, they are used in high-voltage installations, submarine cables, and heavy industrial setups where cable protection and smooth installation are critical.

Conclusion

The use of cable socks in cable installation provides both functional and economic benefits. By protecting cables, improving efficiency, and enhancing safety, they ensure that cable installation projects are completed reliably and cost-effectively. Choosing the right cable sock for your cable type and application is a simple yet highly effective way to enhance installation performance and maintain the long-term integrity of your cable systems.