1.Heavy-Duty Design: The cable roller is made of heavy-duty materials capable of bearing significant cable weight and tensile force, ensuring that the cable remains unharmed during the laying process.

2.Triple Corner Design: 3 x 110mm diameter large waisted steel rollers.The unique triple corner structure allows the roller to easily adapt to various angles of cable laying, enhancing efficiency.

3.Durability: The roller is typically constructed from high-strength, wear-resistant materials to ensure long-term stability and reliability.

4.Zinc plated finish:This finish is commonly used to protect the underlying metal from corrosion and to enhance its durability.

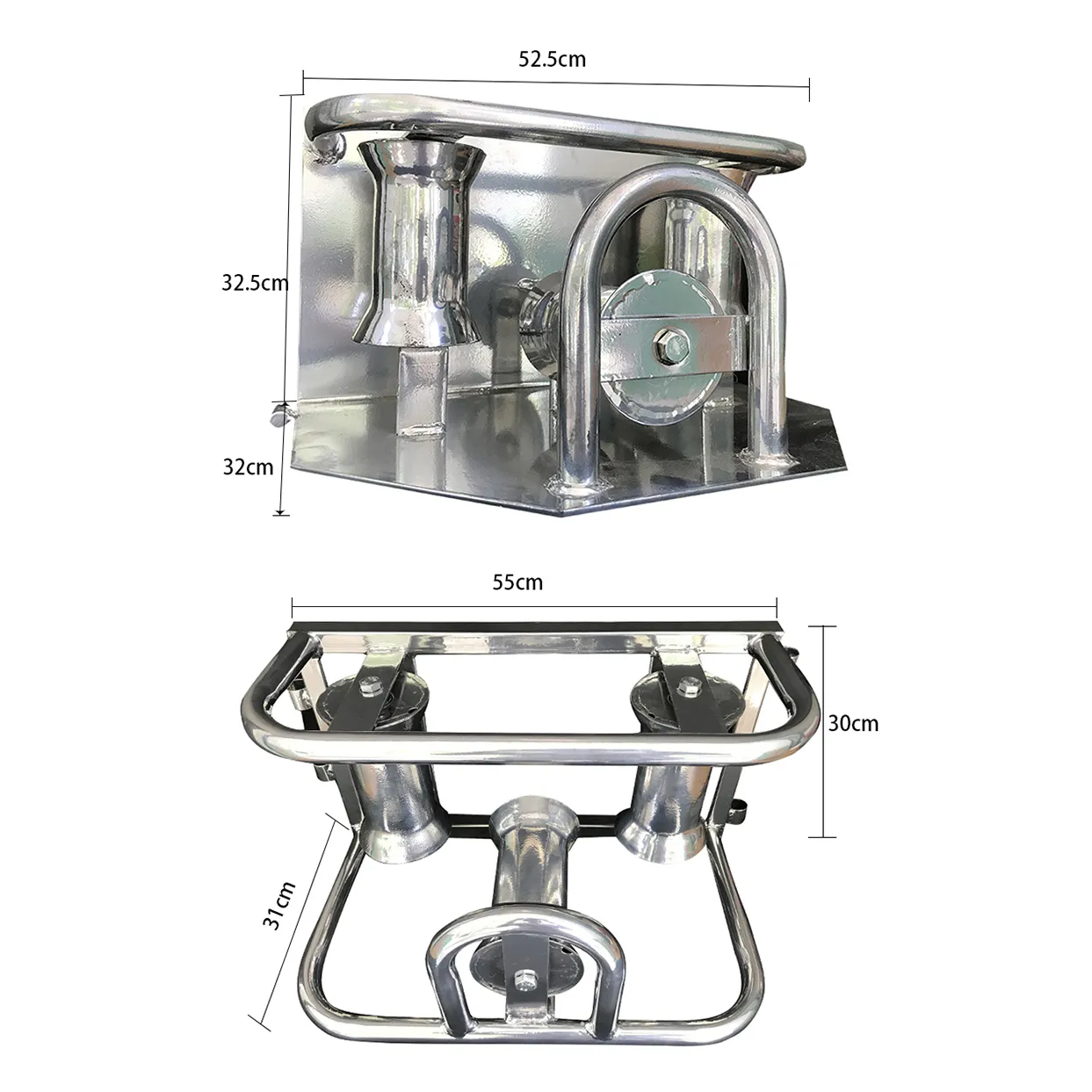

|

Picture |

Model |

Length |

Width |

Height |

Weight |

|

|

HCDL-22 |

55 cm |

31cm |

30 cm |

12 kgs |

|

|

HCDL-23 |

52.5 cm |

32 cm |

32.5 cm |

16 kgs |

Regular Inspections: Regularly inspect the cable roller to ensure its structural integrity and absence of damage or wear.

Cleaning and Lubrication: Regularly clean dirt and dust from the roller surface and apply an appropriate amount of lubricant as needed to reduce friction resistance.

Storage and Preservation: When not in use, store the cable roller in a dry, well-ventilated environment to avoid moisture or corrosion.