1. Cuncepimentu robustu: U rullu di u cavu hè fattu di materiali robusti capaci di suppurtà un pesu significativu di u cavu è una forza di trazione, assicurendu chì u cavu ùn sia dannighjatu durante u prucessu di posa.

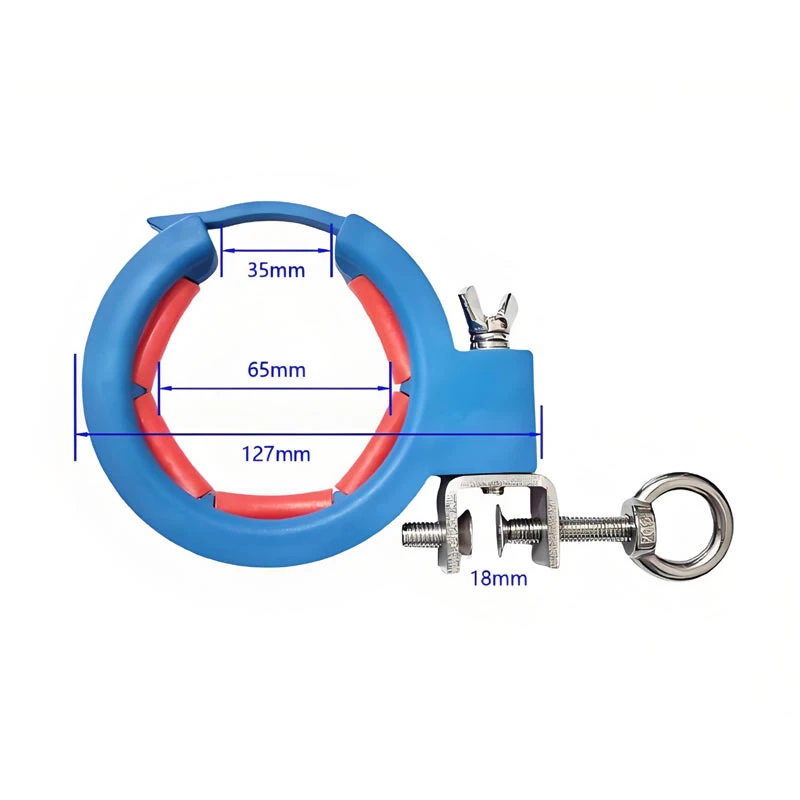

2. Cuncepimentu à trè anguli: 3 rulli d'acciaio à vita larga di 110 mm di diametru. A struttura unica à trè anguli permette à u rullu di adattassi facilmente à diversi anguli di posa di cavi, aumentendu l'efficienza.

3. Durabilità: U rullu hè tipicamente custruitu da materiali d'alta resistenza è resistenti à l'usura per assicurà a stabilità è l'affidabilità à longu andà.

4. Finitura zincata: Questa finitura hè cumunamente aduprata per prutege u metallu sottustante da a currusione è per migliurà a so durabilità.

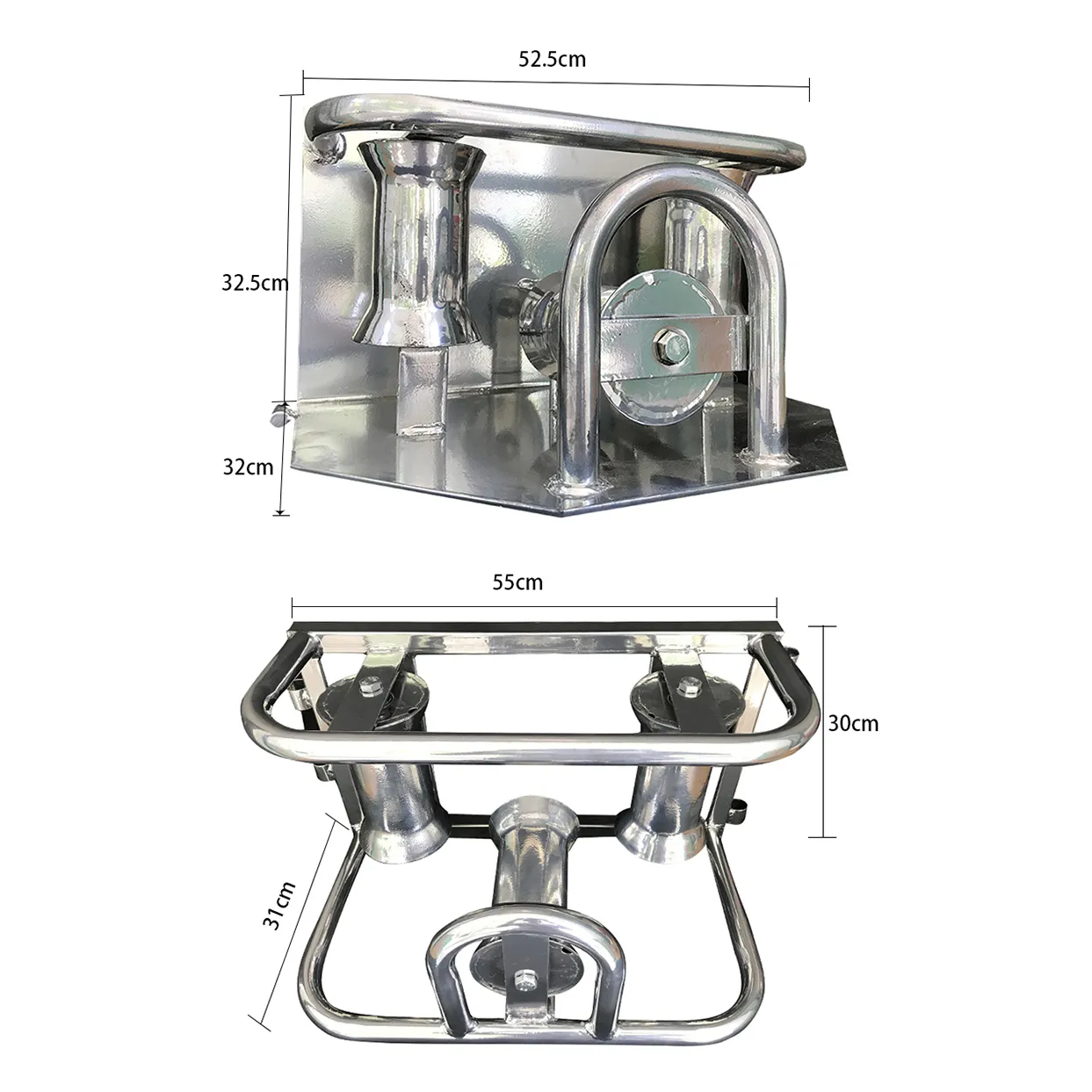

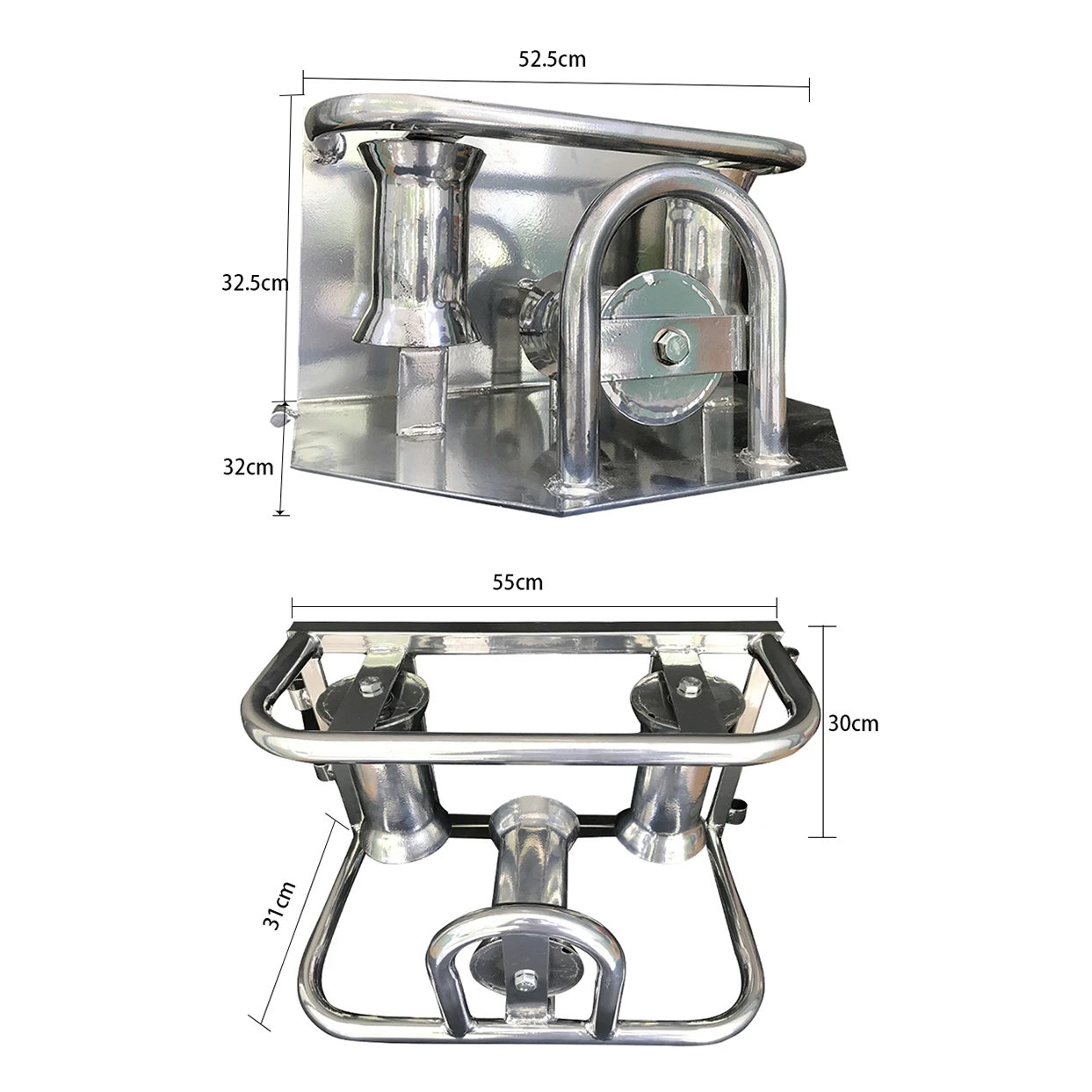

|

Ritrattu |

Mudellu |

Length |

Larghezza |

Altezza |

Pesu |

|

|

HCDL-22 |

55 centimetri |

31 centimetri |

30 centimetri |

12 chilò |

|

|

HCDL-23 |

52,5 centimetri |

32 centimetri |

32,5 centimetri |

16 chilò |

Ispezioni Regulari: Ispezionate regularmente u rullu di u cavu per assicurà a so integrità strutturale è l'assenza di danni o usura.

Pulizia è lubrificazione: Pulite regularmente a terra è a polvere da a superficia di u rullu è applicate una quantità adatta di lubrificante secondu i bisogni per riduce a resistenza à l'attritu.

Immagazzinamentu è cunservazione: Quandu ùn hè micca in usu, almacenate u rullu di cavu in un ambiente seccu è ben ventilatu per evità l'umidità o a corrosione.

Heavy Duty Triple Corner Cable Rollers: Reliable Support for Complex Cable Routes

In modern infrastructure projects, cable installation often involves navigating complex routes with multiple bends and corners. The Heavy Duty Triple Corner Cable Roller is specifically engineered to handle these challenging conditions, ensuring cables are laid smoothly, safely, and efficiently without damage or excessive tension.

This type of cable roller features three high-strength rollers arranged in a triangular configuration, allowing cables to glide easily around 90-degree corners. Each roller is made of aluminum or nylon, mounted on sealed ball bearings for smooth rotation and minimal friction. The frame, constructed from galvanized or powder-coated steel, offers exceptional stability and corrosion resistance—perfect for heavy-duty use in outdoor or industrial environments.

By using triple corner cable rollers, electricians and contractors can prevent cable abrasion, flattening, or insulation damage during installation. The rollers guide the cable through bends seamlessly, maintaining proper alignment and reducing strain on both the cable and pulling equipment. This not only increases installation efficiency but also prolongs the service life of expensive cables.

Commonly used in power transmission, telecommunication networks, and underground cabling projects, these rollers can be paired with straight and vertical rollers to form a complete cable guiding system. Their durable structure, easy handling, and compatibility with different cable diameters make them a reliable choice for professionals working with long cable routes.

For teams looking to improve productivity and safety on site, the Heavy Duty Triple Corner Cable Roller offers the perfect combination of strength, precision, and endurance—making cable installation smoother and more controlled than ever.

The Role of Heavy Duty Triple Corner Cable Rollers in Cable Laying Operations

Efficient and damage-free cable laying is critical to every successful electrical or communication installation project. The Heavy Duty Triple Corner Cable Roller plays an indispensable role in this process, helping guide cables around corners with precision and minimal effort. Its robust design ensures performance even under heavy load and harsh working conditions.

Designed to handle high-tension cable pulling, the triple corner roller consists of three large rollers positioned to form a curved path that supports the cable as it turns. This configuration distributes pressure evenly and prevents cable distortion, making it ideal for projects involving thick power cables or fiber optic lines. The rollers rotate freely to reduce friction, allowing cables to pass through corners smoothly and safely.

Built from reinforced steel frames and wear-resistant rollers, these units are designed for long-term reliability. They are commonly used in underground electrical ducts, power stations, and telecommunication tunnels, where cable routes often include multiple direction changes. The heavy-duty frame ensures the roller remains stable even when used with mechanical winches or in uneven terrain.

One of the key benefits of Heavy Duty Triple Corner Cable Rollers is their ability to protect both the cable and the conduit. By minimizing mechanical stress during pulling, they significantly reduce the risk of cable insulation damage and improve overall installation efficiency. Their modular design also allows easy integration with other cable handling tools such as straight rollers, drum stands, and winches.

For electrical contractors and utility companies, investing in triple corner cable rollers means faster installation, less cable damage, and improved safety standards—making them a vital part of any professional cable laying operation.