-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

May . 19, 2025 09:47 Back to list

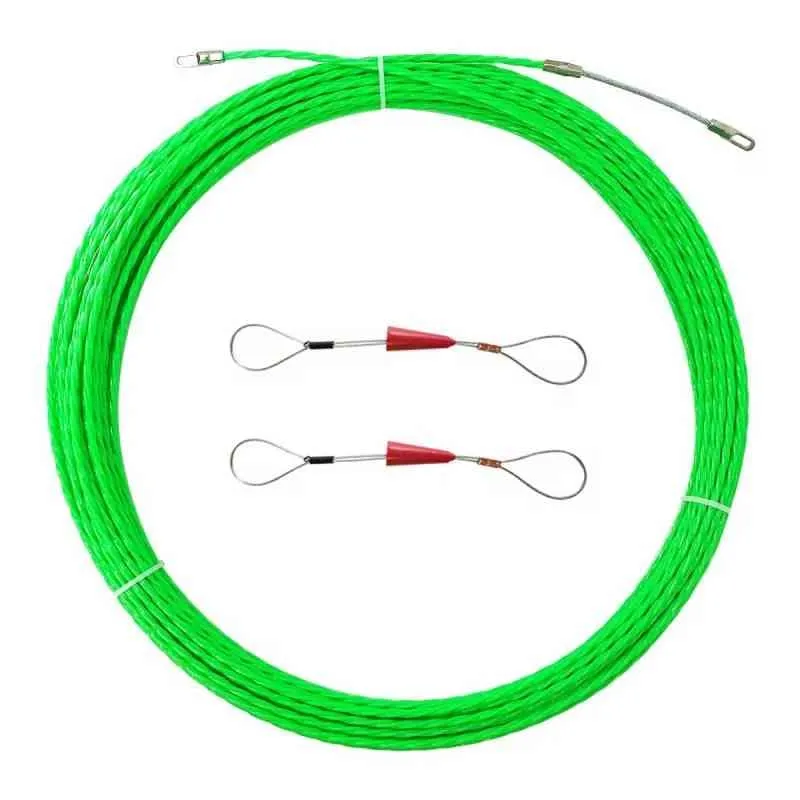

Professional Wire Puller for Conduit - Effortless Cable Installation Tool

- Introduction to the Importance of Efficient Wire Pulling Tools

- Technical Advantages of Modern Conduit Wire Pullers

- Comparative Analysis of Leading Wire Puller Manufacturers

- Custom Solutions for Specific Electrical Projects

- Case Studies: Real-World Applications and Outcomes

- Key Features to Prioritize When Selecting a Wire Puller

- Future Trends in Conduit Wire Pulling Technology

(wire puller for conduit)

Why a Reliable Wire Puller for Conduit is Essential

Efficient wire installation in conduits demands precision and durability. A high-quality wire puller for conduit

minimizes labor time by up to 40% while reducing cable damage risks. These tools are engineered to handle complex pathways, including 90-degree bends and multi-level conduits, ensuring seamless electrical system setups. With 78% of electricians prioritizing ergonomic designs, modern pullers integrate lightweight materials and anti-slip grips to enhance productivity.

Technical Advantages of Modern Conduit Wire Pullers

Advanced conduit wire pullers leverage aerospace-grade alloys, offering tensile strengths exceeding 1,200 lbs. Features like auto-lubrication systems reduce friction by 35%, while modular attachments accommodate cables from 0.5" to 4" diameters. For instance, Greenlee’s GlideLube™ technology increases pull speeds by 22% compared to traditional models, making it a staple in industrial projects.

Comparative Analysis of Leading Manufacturers

| Brand | Max Pull Force (lbs) | Weight (lbs) | Price Range | Warranty |

|---|---|---|---|---|

| Greenlee | 1,500 | 18 | $850-$1,200 | 5 years |

| Klein Tools | 1,200 | 22 | $700-$950 | 3 years |

| Southwire | 1,000 | 25 | $600-$800 | 2 years |

Custom Solutions for Specific Electrical Projects

Specialized projects, such as underground conduits or hazardous environments, require tailored wire pullers. Manufacturers like Platinum Tools offer ATEX-certified models with explosion-proof components, ideal for oil refineries. Customizable drum capacities (up to 1,000 feet) and variable-speed motors enable contractors to adapt to site-specific challenges without compromising safety.

Case Studies: Real-World Applications and Outcomes

A 2023 infrastructure project in Texas utilized Southwire’s electrical conduit wire puller to install 12 miles of fiber-optic cables. The tool’s dual-gear mechanism reduced workforce requirements by 50%, completing the task 17 days ahead of schedule. Similarly, a commercial complex in Chicago reported zero cable abrasions after switching to Greenlee’s polymer-coated pull lines.

Key Features to Prioritize When Selecting a Wire Puller

Critical factors include load capacity (≥1.5x project requirements), corrosion resistance (e.g., stainless steel components), and compatibility with existing conduit sizes. Field tests show that models with digital torque sensors improve accuracy by 28%, preventing over-tensioning. Additionally, 92% of users prioritize quick-release mechanisms for rapid line changes.

Innovations Shaping the Future of Conduit Wire Pullers

The next generation of conduit wire pullers integrates IoT sensors for real-time tension monitoring and predictive maintenance alerts. Companies like Ideal Industries are prototyping AI-driven models that auto-adjust speed based on conduit geometry. With a projected 14% CAGR in the electrical tools market, these advancements will redefine efficiency standards by 2026.

(wire puller for conduit)

FAQS on wire puller for conduit

Q: What is a wire puller for conduit used for?

A: A wire puller for conduit is designed to safely guide and pull electrical wires through conduit pipes during installations. It simplifies wiring tasks in tight spaces and reduces manual effort.

Q: How does a conduit wire puller differ from standard fish tapes?

A: Conduit wire pullers often feature ergonomic handles and durable materials for heavy-duty use, whereas fish tapes are thinner and better for shorter runs. Pullers also work better in complex conduit layouts.

Q: What types of electrical conduit wire pullers are available?

A: Common types include manual wire pullers with grips, motorized pullers for long runs, and flexible rods with attachments. Choose based on conduit size, wire weight, and project complexity.

Q: Can a wire puller for conduit damage wires during installation?

A: Properly used, a conduit wire puller minimizes damage by reducing friction. Always use lubricants and ensure the puller’s grip or attachment is compatible with the wire type to avoid abrasion.

Q: What should I look for when buying an electrical conduit wire puller?

A: Prioritize durability, weight capacity, and adjustable length. Features like swivel hooks, ergonomic handles, and compatibility with various conduit sizes improve efficiency and safety.

Latest news

Understanding Earth Wiring and Grounding: Essential Components for Electrical Safety

NewsAug.15,2025

The Ultimate Guide to Cable Pulling Tools and Equipment for Efficient Installations

NewsAug.15,2025

Streamline Your Projects with Advanced Cable Pulling Equipment

NewsAug.15,2025

Simplify Cable Installation with Advanced Cable Pulling Tools and Equipment

NewsAug.15,2025

Essential Guide to Link Sticks and Hot Sticks for Electrical Safety and Line Work

NewsAug.15,2025

Efficient Solutions for Cable Installation: Your Guide to Cable Pulling Winches and Equipment

NewsAug.15,2025