- Lý tưởng để chạy cáp đa năng phía sau tường, xuyên qua các khoảng trống và dưới sàn nhà.

- Hoàn hảo cho mọi nơi khó tiếp cận!

- Non-metal/non-conductive bright blue polypropylene coated rods protect delicate wires.

- Các thanh được kết nối dễ dàng mang lại sự linh hoạt được kiểm soát. Các thanh kéo dài có thể được kết nối với nhau để đạt được độ dài cần thiết.

- Nhanh hơn và dễ dàng hơn so với cá điện kiểu cũ để chạy cáp. Bây giờ bạn có thể đẩy hoặc kéo cáp bên trong hoặc bên ngoài ống dẫn.

- Xô nhựa trong suốt, dễ dàng mang theo và bảo quản, ống chất liệu pc chắc chắn và cứng cáp.

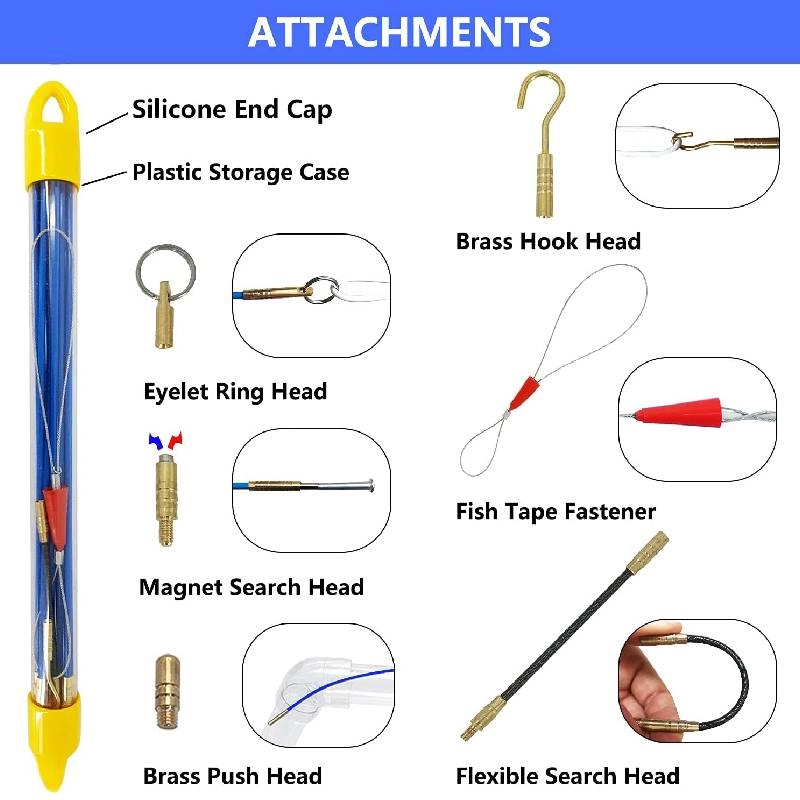

Thông thường, 1 bộ thanh kéo đẩy bao gồm các hạng mục sau:

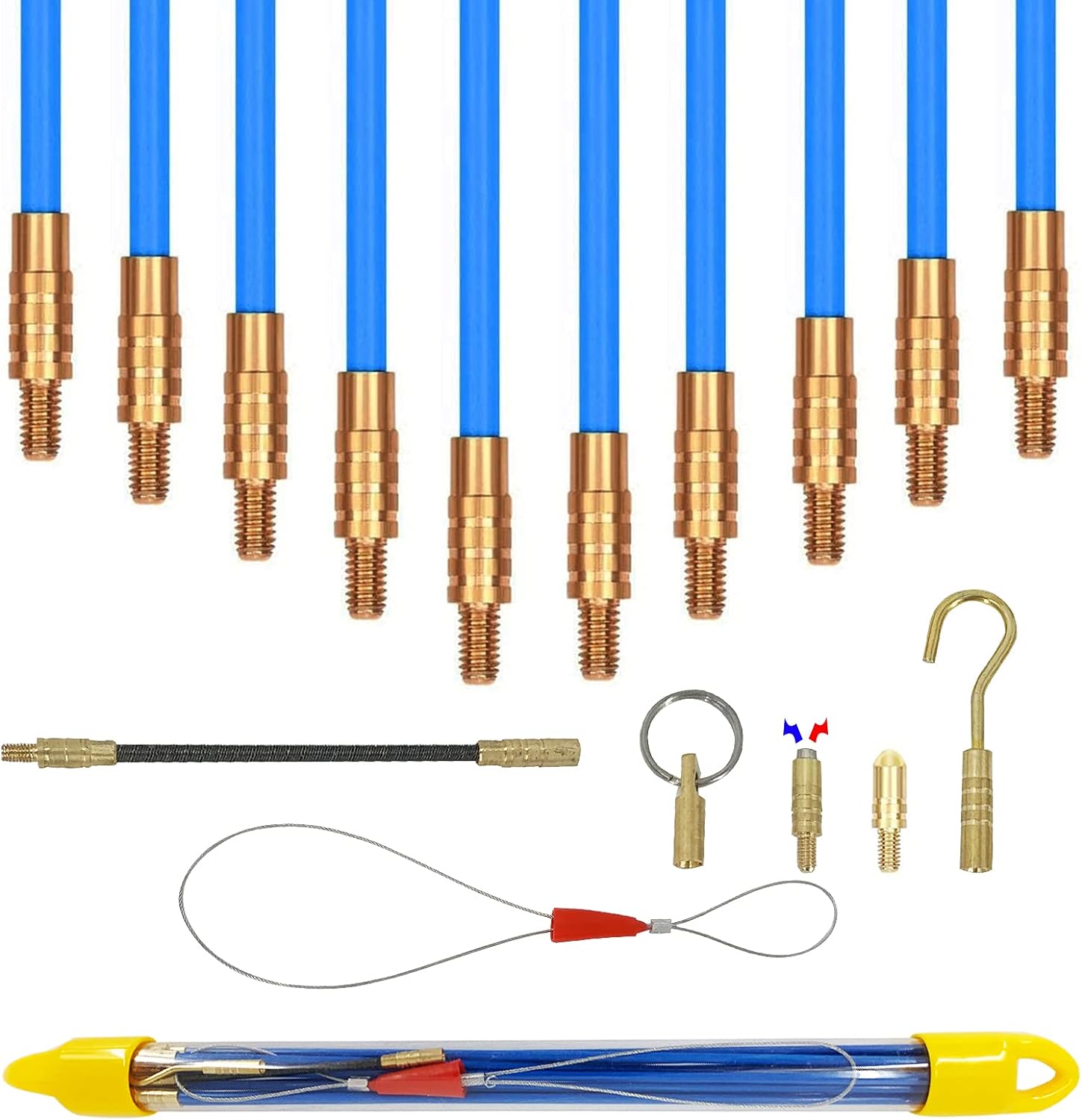

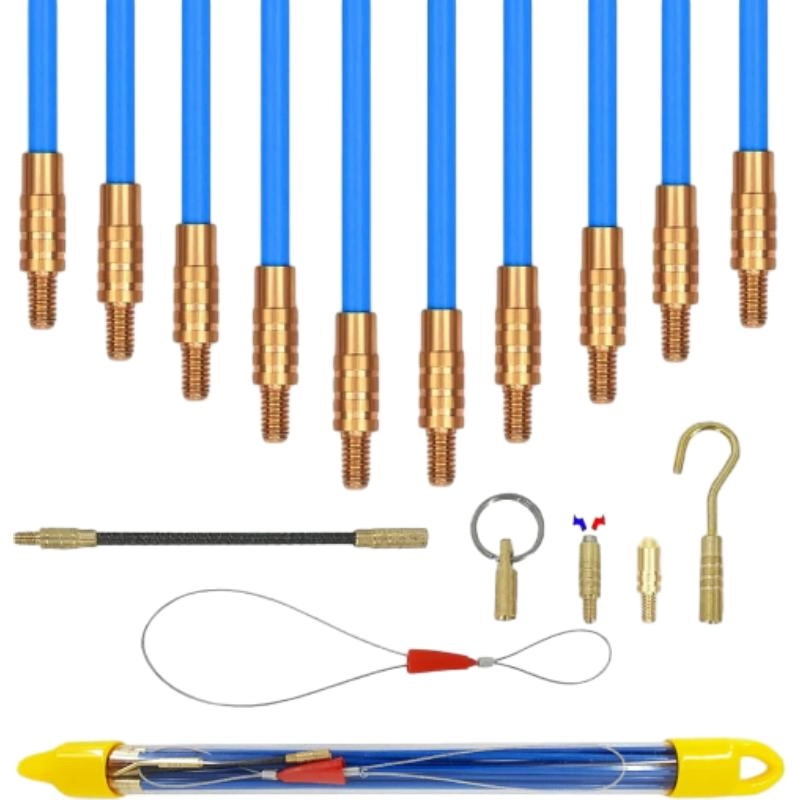

- 10 thanh sợi thủy tinh có đầu nối ở mỗi đầu (một nam / một nữ).

- 1 móc đồng thau - móc bền để bắt cáp hoặc ống dẫn mềm để tháo ra.

- 1 mắt kéo có vòng (vòng gắn vào mắt) - là một công cụ đơn giản để gắn một sợi cáp hoặc dây nhỏ vào đầu thanh, để đẩy hoặc kéo nó vào khu vực được yêu cầu.

- 1 đầu linh hoạt - được làm từ vật liệu dẻo và lò xo, có thể giúp thanh chạy qua các khúc cua hoặc góc hẹp.

- 1 đầu thanh hình cầu, là công cụ để đẩy thanh qua nơi tắc nghẽn mà không bị cản trở hoặc gây hư hỏng.

- 1 dây buộc cá, dùng để giúp dây buộc cá thuận tiện hơn khi sử dụng.

- 1 ống nhựa trong suốt có 2 đầu cắm bên trong。

How to Select the Right Push Pull Rods for Your Equipment

Choosing the correct push pull rods is essential for ensuring smooth motion control, reliable performance, and long-term durability in mechanical systems. These rods are used in a wide variety of applications—from industrial machinery and construction equipment to automotive and aerospace systems—where they transmit linear motion or force efficiently. Selecting the right push pull rod involves understanding its function, load requirements, material properties, and design specifications.

1.Understand the Function of Push Pull Rods

A push pull rod operates as a mechanical linkage that transmits both pushing and pulling forces between two points. It allows motion to be transferred precisely without backlash, making it ideal for throttle control, valve actuation, steering systems, and other mechanical operations. Before selecting a rod, determine the nature of the movement—whether it involves linear actuation, torque transfer, or directional control—since each application may require different configurations.

2. Determine Load Capacity and Strength Requirements

The most critical factor in choosing a push pull rod is its load-bearing capacity. Evaluate the amount of force or stress the rod will experience during operation. If the rod is too weak, it may bend, deform, or fail under pressure. Conversely, an overly strong rod can add unnecessary weight or stiffness. Review your system’s mechanical design to calculate the expected compression and tension forces, then select a rod with sufficient tensile and yield strength to handle those loads safely.

3. Choose the Right Material

Material selection plays a key role in both performance and longevity. Common materials for push pull rods include stainless steel, carbon steel, aluminum, and composite alloys.

Stainless steel rods offer excellent corrosion resistance and are ideal for marine or outdoor applications.

Carbon steel rods provide high strength and are cost-effective for heavy-duty machinery.

Aluminum rods are lightweight and suitable for systems requiring quick, responsive motion.

Composite or fiberglass rods are preferred in environments where electrical insulation and vibration resistance are needed.

4. Consider Design and Adjustment Features

Modern push pull rods often feature adjustable ends, threaded joints, or ball-and-socket connections. These features make installation easier and allow fine-tuning of motion control. For applications that require frequent adjustments or alignment changes, select a design with locking nuts or quick-connect ends. Additionally, ensure that the rod’s diameter and length match your system’s geometry to avoid misalignment or excessive vibration during use.

5. Evaluate Environmental and Operating Conditions

The operating environment has a major impact on performance. High humidity, temperature fluctuations, chemical exposure, or heavy vibration can affect the integrity of push pull rods. In such cases, opt for materials with protective coatings or rods designed with reinforced joints. For outdoor or corrosive conditions, stainless steel or anodized aluminum are the most reliable choices.

Conclusion

Selecting the right push pull rods for your equipment requires a careful balance of strength, material selection, precision, and adaptability. By understanding your system’s specific motion requirements and environmental conditions, you can choose a rod that ensures smooth operation, reduces maintenance needs, and extends equipment lifespan. Investing in high-quality push pull rods not only improves performance but also enhances safety and efficiency in every mechanical application.

The Function and Applications of Push Pull Rods in Mechanical Systems

In the world of mechanical engineering and industrial design, push pull rods play a critical role in transmitting motion and force with precision. These components, often simple in appearance, are essential in systems that require linear actuation, directional control, or synchronized movement. Whether used in heavy machinery, automotive controls, or aerospace assemblies, push pull rods ensure reliable performance and efficient force transfer across a wide range of mechanical systems.

Understanding the Function of Push Pull Rods

A push pull rod functions as a mechanical linkage that transfers both pushing and pulling forces between two points. It acts as a connector between an actuator and the part being moved, allowing precise control of motion without the need for complex mechanisms.- When force is applied in one direction, the rod pushes the connected component; when applied in the opposite direction, it pulls it back. This dual-action capability makes push pull rods ideal for applications requiring smooth, controlled, and reversible motion.

In addition, these rods are designed to maintain rigidity under compression while resisting bending or buckling. High-quality push pull rods provide minimal backlash and excellent stability, which are crucial for maintaining accurate mechanical response in sensitive systems.

2. Key Applications Across Industries

Because of their versatility, push pull rods are found in a wide variety of industrial and engineering applications:

Automotive Systems: Push pull rods are commonly used in throttle linkages, gear shifters, brake systems, and steering assemblies. They ensure smooth transmission of driver inputs to mechanical components.

Aerospace and Aviation: In aircraft control systems, push pull rods are used to transfer pilot commands to control surfaces, such as flaps and rudders, ensuring precise maneuverability and safety.

Industrial Machinery: These rods are crucial in manufacturing and construction equipment, where they help operate levers, valves, and hydraulic systems with controlled linear motion.

Marine Equipment: Corrosion-resistant stainless steel push pull rods are used in boats and ships for throttle and steering control, where durability in harsh environments is vital.

Automation and Robotics: In automated systems, push pull rods enable accurate linear actuation, helping robotic arms or conveyor systems perform repetitive movements with high precision.

3. Design and Material Considerations

The effectiveness of push pull rods depends largely on their design and material composition. Common materials include stainless steel, aluminum, and carbon steel, chosen for their strength, durability, and corrosion resistance. The rod ends are often fitted with ball joints, clevises, or threaded connectors, allowing flexibility and easy integration into various mechanical setups.

Proper selection of rod diameter and wall thickness ensures the component can withstand the required load without deformation. In high-performance applications such as aerospace, lightweight composite materials are sometimes used to reduce overall system weight while maintaining strength and rigidity.

4. Advantages in Mechanical Systems

The use of push pull rods offers multiple benefits:

Precise motion transfer with minimal energy loss.

Simplified design compared to cable or hydraulic systems.

Reduced maintenance requirements due to durable construction.

Compatibility with a wide range of mechanical configurations.

Conclusion

In summary, push pull rods are indispensable components in modern mechanical systems, providing accurate, efficient, and durable force transmission. Their ability to handle both compression and tension makes them ideal for diverse industrial, automotive, and aerospace applications. By choosing high-quality materials and appropriate designs, engineers can ensure optimal system performance, safety, and longevity across all operating conditions.

High-Strength Push Pull Rods for Industrial and Automotive Use

In demanding industrial and automotive environments, components must withstand extreme loads, vibration, and continuous motion without compromising performance. Among these critical components, high-strength push pull rods play a vital role in ensuring precise motion control and reliable force transmission. These rods are engineered to deliver both durability and stability, making them ideal for heavy-duty machinery, vehicles, and equipment that operate under challenging conditions.

1.The Importance of Strength and Reliability

A push pull rod functions as a linear actuator, transmitting mechanical force in both directions—pushing and pulling—between two components. In industrial and automotive systems, where accuracy and responsiveness are essential, a high-strength rod ensures consistent performance even under high stress. Whether used in steering mechanisms, gear linkages, throttle control, or hydraulic systems, the rod must maintain its structural integrity to prevent misalignment, bending, or mechanical failure.

High-strength push pull rods are specifically designed to handle greater tensile and compressive forces compared to standard models. Their enhanced rigidity helps reduce vibration and deflection, allowing smoother and more efficient operation in heavy-duty systems.

2. Superior Materials for Tough Environments

Material selection is key to achieving strength and durability. Stainless steel and carbon steel are among the most common materials used in high-strength push pull rods.- Stainless steel provides excellent corrosion resistance, making it suitable for outdoor or marine environments where moisture and chemicals are present. Carbon steel, on the other hand, offers superior load-bearing capacity and is often used in industrial machinery and automotive drive systems.

For applications requiring lightweight yet strong components—such as in performance vehicles or aerospace systems—aluminum alloys or composite materials can be used. These materials reduce weight without sacrificing mechanical strength, contributing to improved efficiency and fuel savings.

3. Precision Engineering and Design Features

High-quality push pull rods are engineered with precision threads, reinforced ends, and secure locking mechanisms to ensure stable and reliable connections. Some models incorporate ball joints, clevis ends, or adjustable fittings that allow easy installation and alignment adjustments. Advanced designs may also feature anti-corrosion coatings, heat treatment, or surface hardening to enhance wear resistance and extend service life.

The precision design of these rods ensures smooth movement and minimal backlash, which is especially important in systems that require accurate control—such as transmission linkages, industrial automation, or robotic systems.

4. Applications in Industrial and Automotive Fields

In industrial machinery, high-strength push pull rods are used for operating valves, actuating control levers, and managing hydraulic or pneumatic systems. Their durability ensures reliable performance even in high-vibration environments such as construction or manufacturing equipment.

In automotive applications, these rods are commonly used in gear shift linkages, brake systems, and throttle controls. They ensure responsive operation and safety under constant load and movement. Heavy trucks, off-road vehicles, and high-performance cars often depend on high-strength rods to maintain stability and precision in demanding conditions.

Conclusion

High-strength push pull rods are essential components for ensuring performance, reliability, and safety in both industrial and automotive applications. By combining superior materials, precision engineering, and robust design, these rods deliver consistent force transmission under even the harshest conditions. Investing in high-quality push pull rods not only enhances equipment durability but also improves overall operational efficiency and control. Whether in a factory setting or on the road, the right push pull rod can make all the difference in achieving smooth, safe, and efficient mechanical performance.