Đặc trưng

Đặc trưng

- Thanh sợi thủy tinh bên trong: Quy trình đùn làm từ sợi thủy tinh E và nhựa chất lượng cao ở nhiệt độ cao.

- Thanh sợi thủy tinh bên ngoài: polymer phát triển

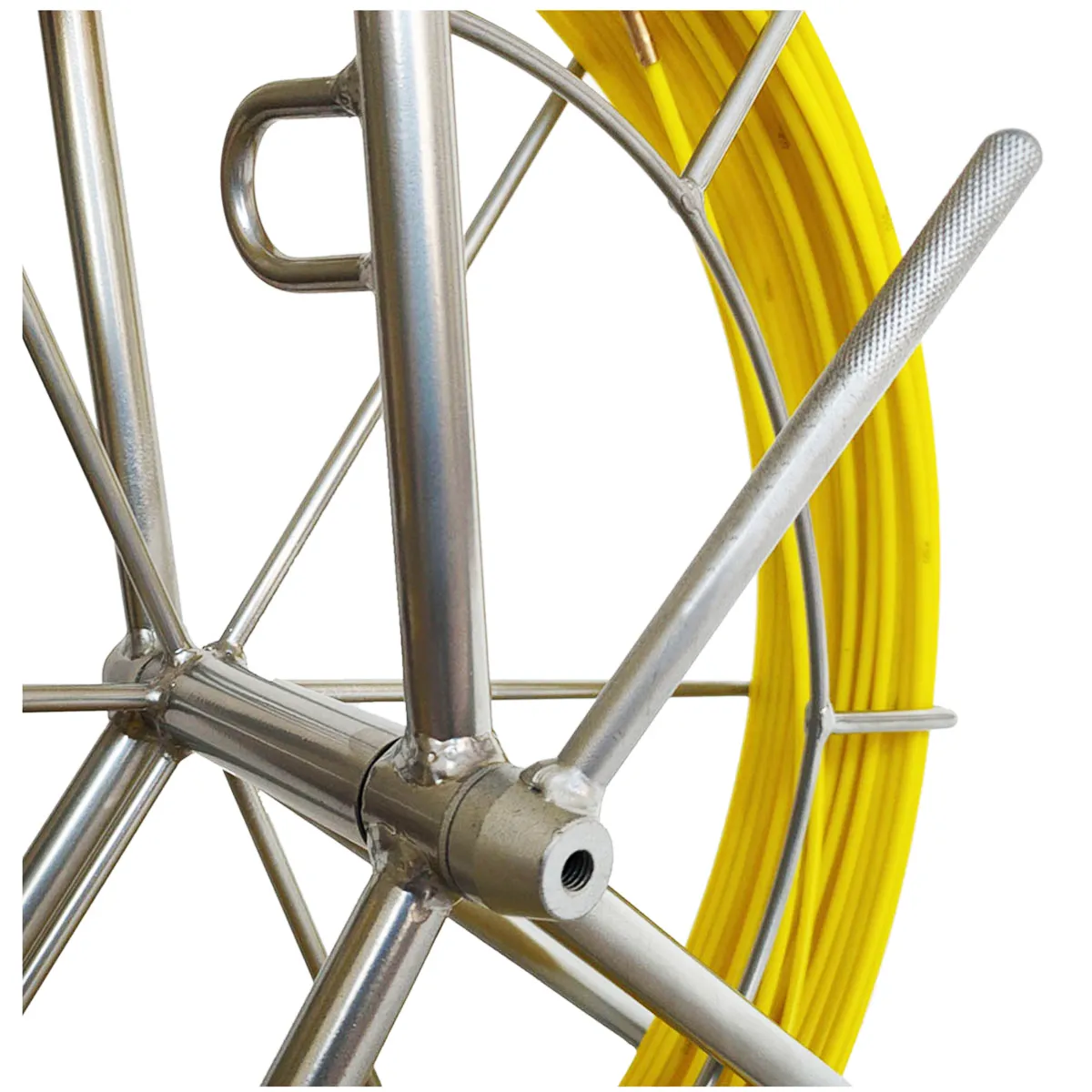

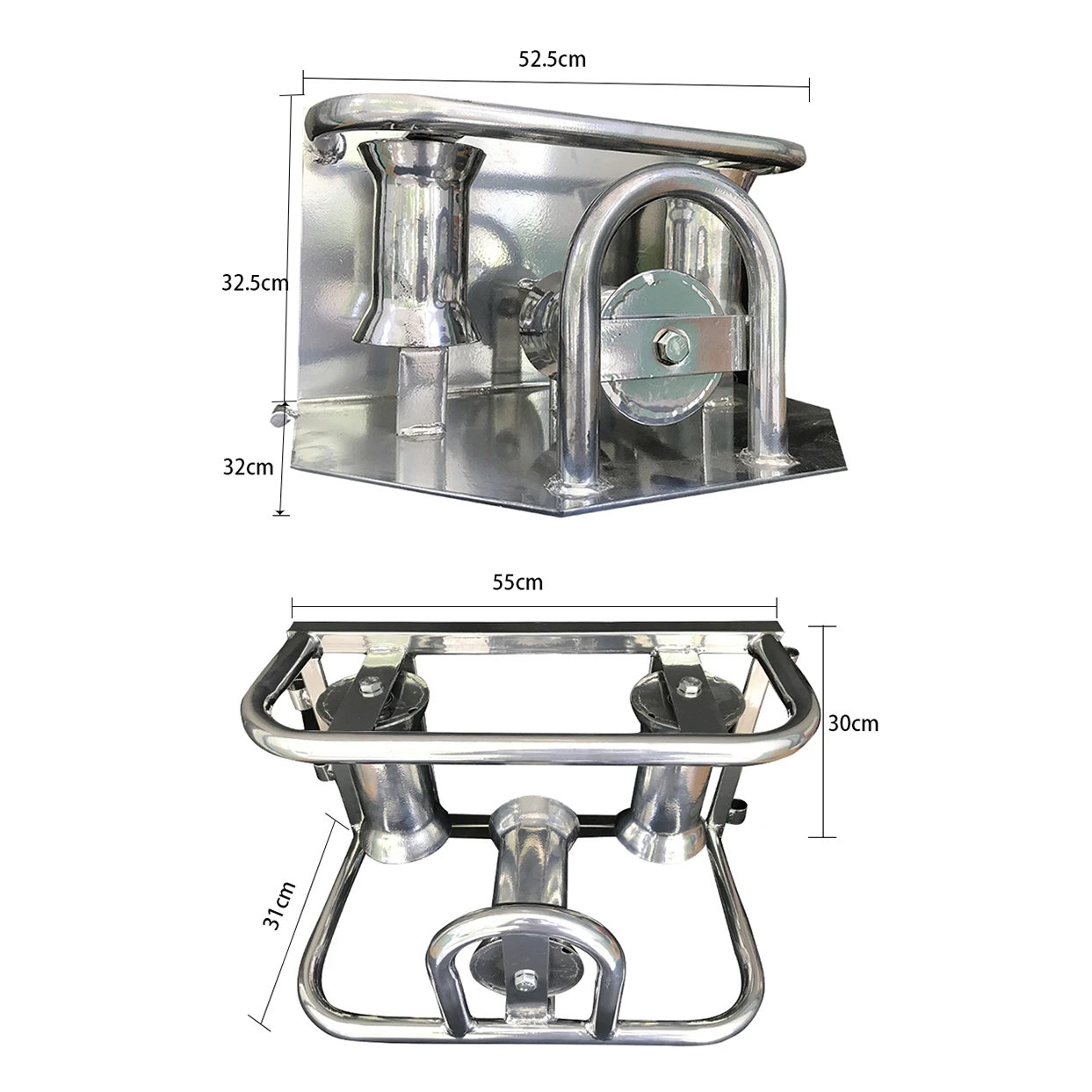

- Lắp ráp: khung kim loại sơn tĩnh điện; bánh xe cao su lắp ráp để dễ vận chuyển; Con lăn dẫn hướng cho khớp nối quay; phanh đỗ xe để điều khiển thanh linh hoạt.

- Dây đồng bên trong là tùy chọn, dùng để theo dõi dễ dàng hoặc sử dụng cho mục đích chuyên nghiệp khác.

- Lồng ổ trục lăn giúp di chuyển chắc chắn và dễ sử dụng.

- Thiết bị nạp cho phép thanh vào và ra một cách trơn tru

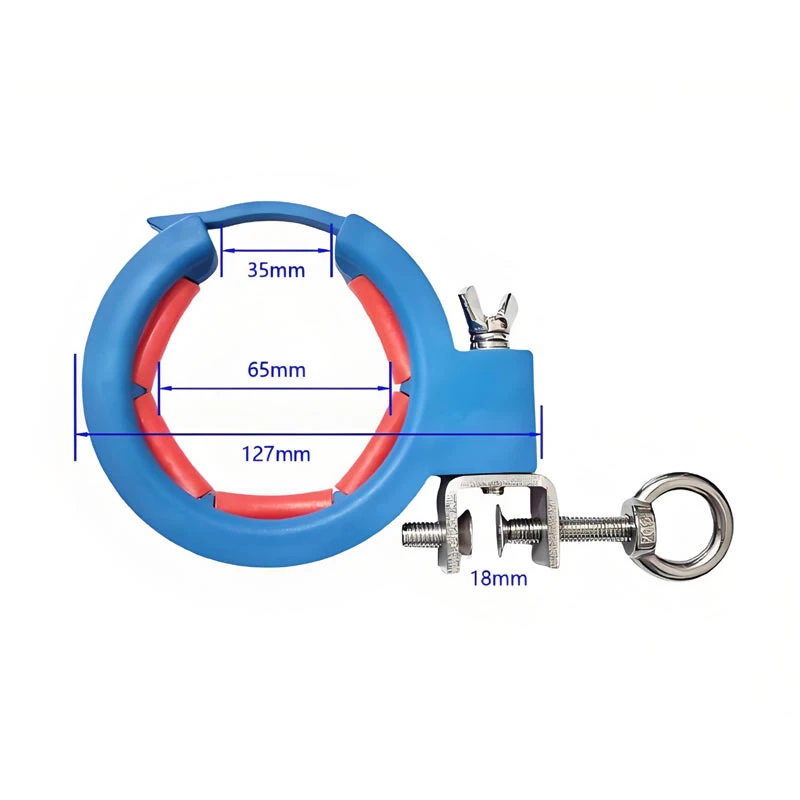

- Đầu kéo mũi bò chống gỉ với nhiều phụ kiện đa dạng.

Sự chỉ rõ

Sự chỉ rõ

|

Đường kính thanh. (mm) |

Cân nặng (g/m3) |

Bán kính uốn cong (cm) |

Đề xuất chiều dài (m) |

Đề xuất tối đa. duct Dia. (mm) |

Lõi bên trong Anh ấy. (mm) |

Độ võng gãy/mm |

Độ uốn tối đa lực(kn) |

Độ bền kéo (kn) |

|

4 |

19 |

5 |

80 |

50 |

3 |

6.9 |

0.21 |

|

|

4.5 |

22 |

5 |

80 |

50 |

3 |

|||

|

5 |

32 |

6 |

100 |

60 |

4 |

6.9 |

0.366 |

|

|

6 |

40 |

6 |

100 |

60 |

4 |

|||

|

7 |

66 |

10 |

150 |

80 |

6 |

7.0 |

0.825 |

350 |

|

8 |

77 |

10 |

200 |

80 |

6 |

|||

|

9 |

100 |

15 |

200 |

100 |

7 |

7.1 |

1.24 |

2000 |

|

10 |

125 |

18 |

250 |

200 |

8/8.5 |

7.1 |

1.68 |

2800 |

|

11 |

148 |

20 |

250 |

200 |

8.5 |

|||

|

12 |

165 |

20 |

300 |

200 |

8.5 |

|||

|

13 |

205 |

25 |

300 |

250 |

10 |

7.3 |

1.86 |

3000 |

|

14 |

225 |

25 |

300 |

250 |

10 |

|||

|

15 |

283 |

32 |

200 |

300 |

12 |

7.3 |

2.97 |

3500 |

|

16 |

305 |

32 |

200 |

300 |

12 |

|

Kích thước lồng (cm) |

50x41x18 |

58x49x18 |

67x57x18 |

80*70*25 |

98x90x45 |

108x100x45 |

118*110*45 |

140*130*45 |

|

Thanh D. 4.5mm |

100m |

150 phút |

--- |

--- |

--- |

--- |

--- |

--- |

|

Thanh D. 6 mm |

--- |

100m |

150 phút |

--- |

--- |

--- |

--- |

--- |

|

Thanh D. 8 mm |

--- |

--- |

--- |

100m |

200m |

--- |

--- |

--- |

|

Thanh D. 9 mm |

--- |

--- |

--- |

--- |

150 phút |

200m |

--- |

--- |

|

Thanh D. 10 mm |

--- |

--- |

--- |

--- |

--- |

150 phút |

350m |

--- |

|

Thanh D. 11 mm |

--- |

--- |

--- |

--- |

--- |

--- |

300m |

--- |

|

Thanh D. 12 mm |

--- |

--- |

--- |

--- |

--- |

--- |

300m |

--- |

|

Thanh D. 13 mm |

--- |

--- |

--- |

--- |

--- |

--- |

250m |

--- |

|

Thanh D. 14 mm |

--- |

--- |

--- |

--- |

--- |

--- |

200m |

300m |

|

Thanh D. 16 mm |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

250m |

|

Trọng lượng (kg) |

2 |

2.4 |

2.9 |

4.5 |

19 |

23 |

28 |

35 |

Sản vật được trưng bày

Sản vật được trưng bày

Cable Pulling Equipment: Efficient Tools for Smooth Cable Installation

In modern infrastructure projects, efficient cable installation is crucial for maintaining productivity and minimizing downtime. Cable pulling equipment plays an essential role in helping electricians, telecommunication engineers, and utility workers lay cables quickly and safely through ducts, conduits, and underground systems. Among these tools, the Fiberglass Cable Duct Rodder stands out for its strength, flexibility, and reliability.

A fiberglass duct rodder consists of a solid fiberglass core with a high-tensile strength, coated with a smooth resin layer that reduces friction while pulling cables. The rod is housed on a sturdy steel or aluminum frame, making it easy to transport and operate on job sites. Its non-conductive nature also ensures user safety when working around electrical installations.

One of the main advantages of fiberglass rodders is their ability to navigate long or curved conduits where traditional pulling methods fail. They can push through bends and obstructions without kinking, allowing workers to pull cables over extended distances efficiently. This makes them ideal for power lines, data cables, and communication networks.

In addition, cable pulling equipment such as winches, pulling grips, and lubricants are often used together with fiberglass duct rodders to improve workflow and reduce cable damage. For professionals seeking durability, versatility, and safety in their cable installation projects, fiberglass cable duct rodders remain one of the most trusted solutions on the market.

Fiberglass Duct Rodder Applications: Reliable Solutions for Utility and Construction

The Fiberglass Duct Rodder has become a must-have tool for technicians working in utilities, telecommunications, and construction. Designed for tracing, locating, and pulling cables through conduits, this innovative equipment simplifies tasks that once required extensive manual labor. Its wide range of applications makes it indispensable for both small-scale maintenance and large infrastructure projects.

In the telecommunication industry, fiberglass duct rodders are used to install fiber optic cables through underground ducts or wall-mounted conduits. Their flexibility allows them to travel through narrow or curved pathways, ensuring that cables can be laid smoothly without damage. For electrical construction, they help guide power cables safely through protective piping systems, reducing the risk of short circuits and mechanical strain.

Utility companies also use fiberglass rodders for pipeline and sewer inspection, as they can carry cameras or detectors through pipelines to identify blockages or damages. In addition, their non-conductive fiberglass structure ensures safety when working around live circuits or metal structures.

Available in various lengths and diameters, fiberglass duct rodders can be customized for specific tasks. Whether it’s for underground cable pulling, conduit cleaning, or duct mapping, their durability and resistance to corrosion make them suitable for both indoor and outdoor use.

By combining flexibility, strength, and ease of operation, fiberglass duct rodders continue to deliver outstanding performance, making them a reliable partner in every modern utility and construction environment.