Aýratynlyklary

Aýratynlyklary

- Içindäki süýümli aýna çybyk: E-süýümli aýnadan we ýokary temperaturada ýokary hilli rezinden ýasalan ekstrudirlenen proses.

- Süýümli aýna çybyk daşky: ösen polimer

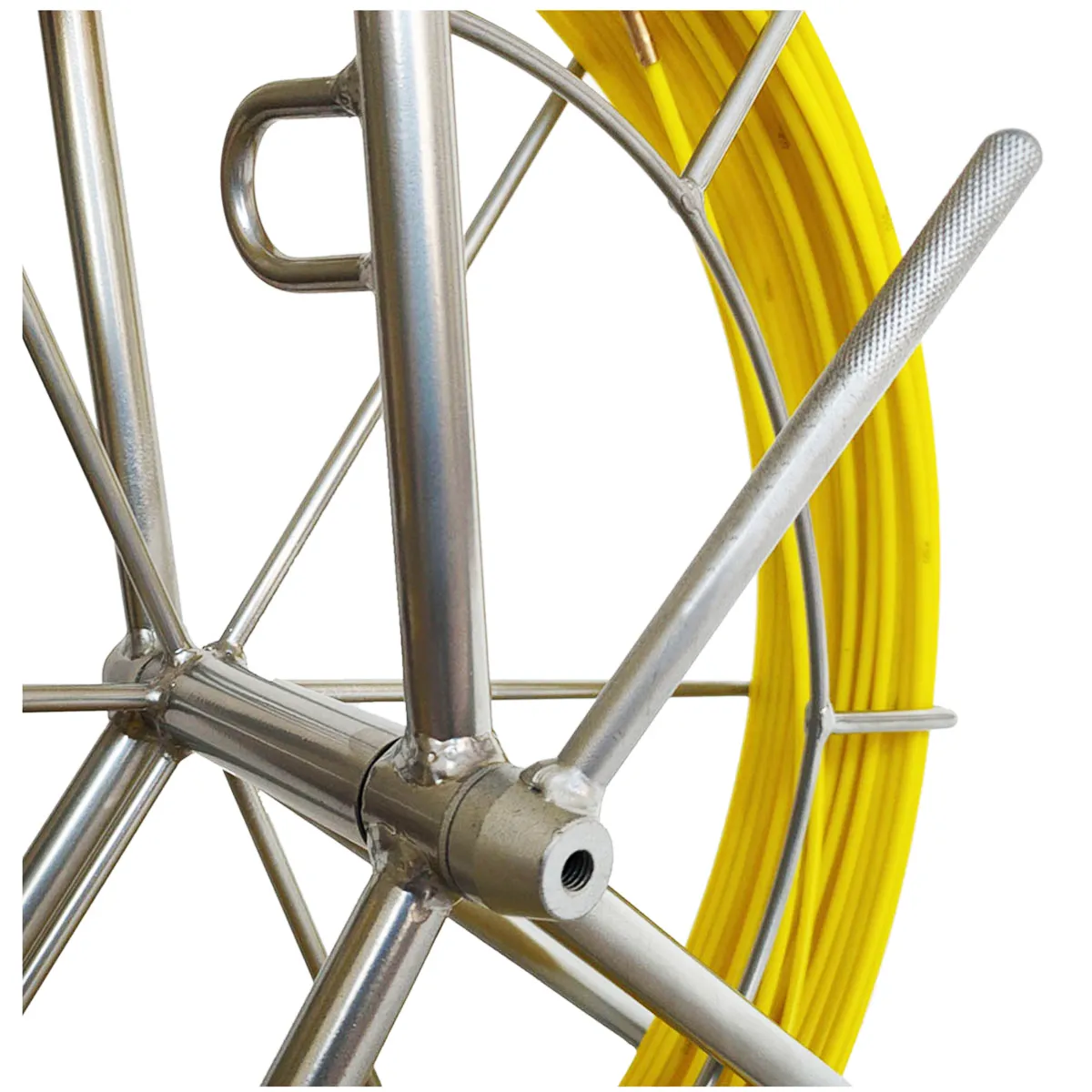

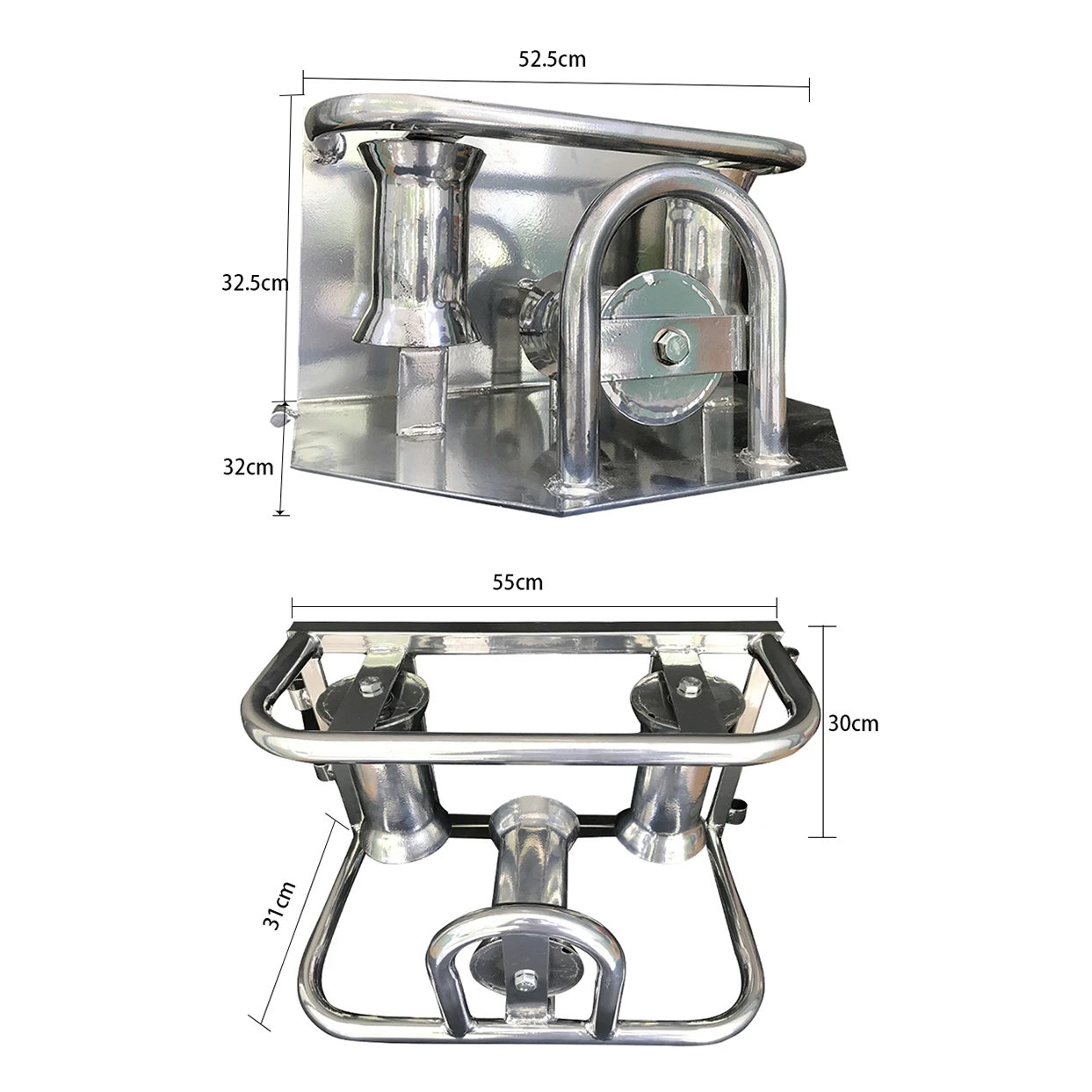

- Gurnama: metal çarçuwaly poroşok bilen örtülen; aňsat daşamak üçin rezin tigirleri ýygnamak; Aýlanma birikdirmek üçin gollanma rolikleri; çeýe çybyk dolandyryşy üçin duralga tormozy.

- Içindäki mis sim, aňsat ýa-da başga hünär taýdan ulanmak üçin hökmanydyr.

- Hereket üçin rulonly rulman berk we ulanmak aňsat.

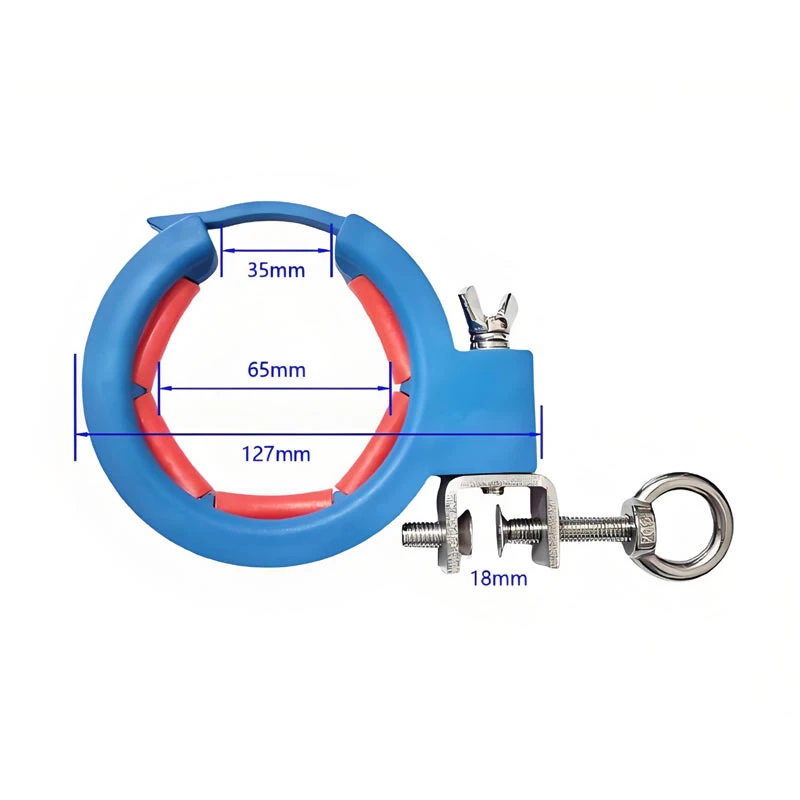

- Iýmit enjamy çybyklara rahat we çykmaga mümkinçilik berýär

- Dürli garnituralar bilen poslamaýan öküz-burun çekmek maslahatlary.

Spesifikasiýa

Spesifikasiýa

|

Rod Dia. (mm) |

Agram (g / m) |

Egilme radiusy (sm) |

Teklip edilýär uzynlygy (m) |

Teklip edilýän iň ýokary duct Dia. (mm) |

Içki ýadro Ol. (mm) |

Bölünmek / mm |

Maks. egilmek güýç (kn) |

Dartyş güýji (kn) |

|

4 |

19 |

5 |

80 |

50 |

3 |

6.9 |

0.21 |

|

|

4.5 |

22 |

5 |

80 |

50 |

3 |

|||

|

5 |

32 |

6 |

100 |

60 |

4 |

6.9 |

0.366 |

|

|

6 |

40 |

6 |

100 |

60 |

4 |

|||

|

7 |

66 |

10 |

150 |

80 |

6 |

7.0 |

0.825 |

350 |

|

8 |

77 |

10 |

200 |

80 |

6 |

|||

|

9 |

100 |

15 |

200 |

100 |

7 |

7.1 |

1.24 |

2000 |

|

10 |

125 |

18 |

250 |

200 |

8/8.5 |

7.1 |

1.68 |

2800 |

|

11 |

148 |

20 |

250 |

200 |

8.5 |

|||

|

12 |

165 |

20 |

300 |

200 |

8.5 |

|||

|

13 |

205 |

25 |

300 |

250 |

10 |

7.3 |

1.86 |

3000 |

|

14 |

225 |

25 |

300 |

250 |

10 |

|||

|

15 |

283 |

32 |

200 |

300 |

12 |

7.3 |

2.97 |

3500 |

|

16 |

305 |

32 |

200 |

300 |

12 |

|

Keýpiň ululyklary (sm) |

50x41x18 |

58x49x18 |

67x57x18 |

80*70*25 |

98x90x45 |

108x100x45 |

118*110*45 |

140*130*45 |

|

Rod D. 4.5mm |

100m |

150m |

--- |

--- |

--- |

--- |

--- |

--- |

|

Rod D. 6 mm |

--- |

100m |

150m |

--- |

--- |

--- |

--- |

--- |

|

Rod D. 8 mm |

--- |

--- |

--- |

100m |

200m |

--- |

--- |

--- |

|

Rod D. 9 mm |

--- |

--- |

--- |

--- |

150m |

200m |

--- |

--- |

|

Rod D. 10 mm |

--- |

--- |

--- |

--- |

--- |

150m |

350m |

--- |

|

Rod D. 11 mm |

--- |

--- |

--- |

--- |

--- |

--- |

300m |

--- |

|

Rod D. 12 mm |

--- |

--- |

--- |

--- |

--- |

--- |

300m |

--- |

|

Rod D. 13 mm |

--- |

--- |

--- |

--- |

--- |

--- |

250m |

--- |

|

Rod D. 14 mm |

--- |

--- |

--- |

--- |

--- |

--- |

200m |

300m |

|

Rod D. 16 mm |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

250m |

|

Agramy (kg) |

2 |

2.4 |

2.9 |

4.5 |

19 |

23 |

28 |

35 |

Önümiň görkezilmegi

Önümiň görkezilmegi

Cable Pulling Equipment: Efficient Tools for Smooth Cable Installation

In modern infrastructure projects, efficient cable installation is crucial for maintaining productivity and minimizing downtime. Cable pulling equipment plays an essential role in helping electricians, telecommunication engineers, and utility workers lay cables quickly and safely through ducts, conduits, and underground systems. Among these tools, the Fiberglass Cable Duct Rodder stands out for its strength, flexibility, and reliability.

A fiberglass duct rodder consists of a solid fiberglass core with a high-tensile strength, coated with a smooth resin layer that reduces friction while pulling cables. The rod is housed on a sturdy steel or aluminum frame, making it easy to transport and operate on job sites. Its non-conductive nature also ensures user safety when working around electrical installations.

One of the main advantages of fiberglass rodders is their ability to navigate long or curved conduits where traditional pulling methods fail. They can push through bends and obstructions without kinking, allowing workers to pull cables over extended distances efficiently. This makes them ideal for power lines, data cables, and communication networks.

In addition, cable pulling equipment such as winches, pulling grips, and lubricants are often used together with fiberglass duct rodders to improve workflow and reduce cable damage. For professionals seeking durability, versatility, and safety in their cable installation projects, fiberglass cable duct rodders remain one of the most trusted solutions on the market.

Fiberglass Duct Rodder Applications: Reliable Solutions for Utility and Construction

The Fiberglass Duct Rodder has become a must-have tool for technicians working in utilities, telecommunications, and construction. Designed for tracing, locating, and pulling cables through conduits, this innovative equipment simplifies tasks that once required extensive manual labor. Its wide range of applications makes it indispensable for both small-scale maintenance and large infrastructure projects.

In the telecommunication industry, fiberglass duct rodders are used to install fiber optic cables through underground ducts or wall-mounted conduits. Their flexibility allows them to travel through narrow or curved pathways, ensuring that cables can be laid smoothly without damage. For electrical construction, they help guide power cables safely through protective piping systems, reducing the risk of short circuits and mechanical strain.

Utility companies also use fiberglass rodders for pipeline and sewer inspection, as they can carry cameras or detectors through pipelines to identify blockages or damages. In addition, their non-conductive fiberglass structure ensures safety when working around live circuits or metal structures.

Available in various lengths and diameters, fiberglass duct rodders can be customized for specific tasks. Whether it’s for underground cable pulling, conduit cleaning, or duct mapping, their durability and resistance to corrosion make them suitable for both indoor and outdoor use.

By combining flexibility, strength, and ease of operation, fiberglass duct rodders continue to deliver outstanding performance, making them a reliable partner in every modern utility and construction environment.