-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

Jan . 26, 2025 02:30 Back to list

Cable Clamp

Panel box wire clamps are an essential component in electrical systems, serving as the backbone for securing and organizing cables within an enclosure. In an era where energy efficiency and safety are paramount, choosing the right wire clamps impacts both operational stability and compliance with electrical standards.

Authoritativeness in discussing wire clamps comes with understanding industry standards and certifications. High-quality wire clamps often meet specific standards such as UL (Underwriters Laboratories) or CE (Conformité Européenne), which guarantee safety and performance. These certifications provide assurance that the product has undergone rigorous testing and complies with internationally recognized benchmarks, fostering confidence among users. Moreover, engaging with manufacturers that have a long-standing reputation in the industry adds a layer of trust. Companies with decades of experience in producing electrical components typically offer extensive warranty and customer support. Their product lines are often evolved based on real-time feedback and technological advancements, meaning they stay ahead in providing solutions that answer modern electrical challenges. Trustworthiness, the cornerstone of any component, is achieved through consistent performance and reliability. End-users, from electricians to engineers, prefer wire clamps that have proven their resilience and functionality over time. Brands that offer user testimonials and case studies further establish this trust by providing evidence of successful deployments across various applications. In conclusion, panel box wire clamps are more than mere accessories; they are integral to the safety and efficiency of electrical systems. By leveraging expertise in materials and design, aligning with authoritative standards, and delivering trustworthy performance, wire clamps provide essential protection and organization for wiring infrastructures. Whether in residential, commercial, or industrial environments, the right wire clamp selection facilitates a durable and safe electrical system, underscoring their indispensable role in modern setups.

Authoritativeness in discussing wire clamps comes with understanding industry standards and certifications. High-quality wire clamps often meet specific standards such as UL (Underwriters Laboratories) or CE (Conformité Européenne), which guarantee safety and performance. These certifications provide assurance that the product has undergone rigorous testing and complies with internationally recognized benchmarks, fostering confidence among users. Moreover, engaging with manufacturers that have a long-standing reputation in the industry adds a layer of trust. Companies with decades of experience in producing electrical components typically offer extensive warranty and customer support. Their product lines are often evolved based on real-time feedback and technological advancements, meaning they stay ahead in providing solutions that answer modern electrical challenges. Trustworthiness, the cornerstone of any component, is achieved through consistent performance and reliability. End-users, from electricians to engineers, prefer wire clamps that have proven their resilience and functionality over time. Brands that offer user testimonials and case studies further establish this trust by providing evidence of successful deployments across various applications. In conclusion, panel box wire clamps are more than mere accessories; they are integral to the safety and efficiency of electrical systems. By leveraging expertise in materials and design, aligning with authoritative standards, and delivering trustworthy performance, wire clamps provide essential protection and organization for wiring infrastructures. Whether in residential, commercial, or industrial environments, the right wire clamp selection facilitates a durable and safe electrical system, underscoring their indispensable role in modern setups.

Next:

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

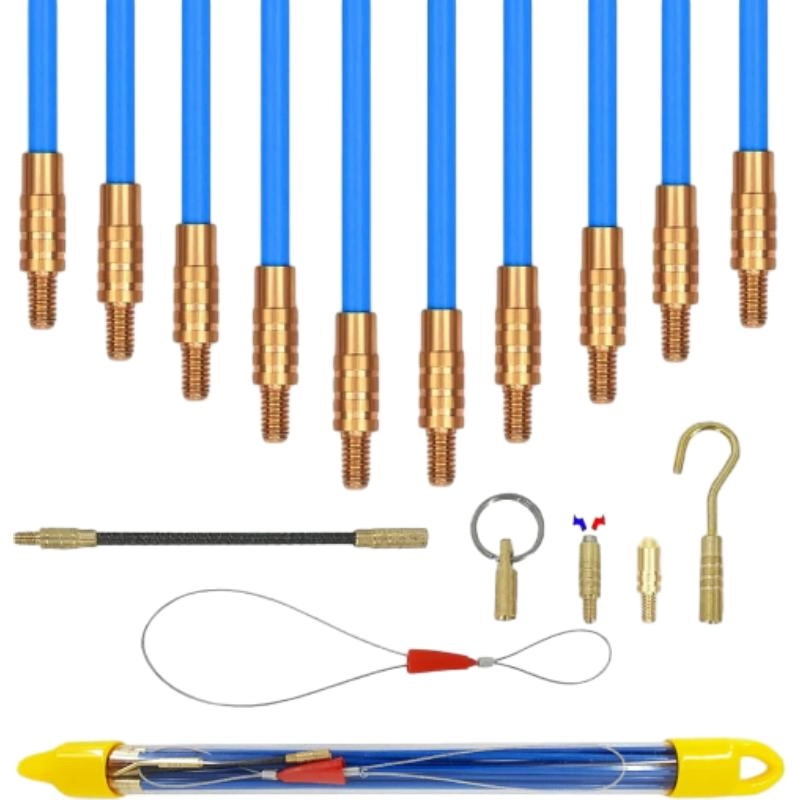

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy