-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

Jan . 26, 2025 02:08 Back to list

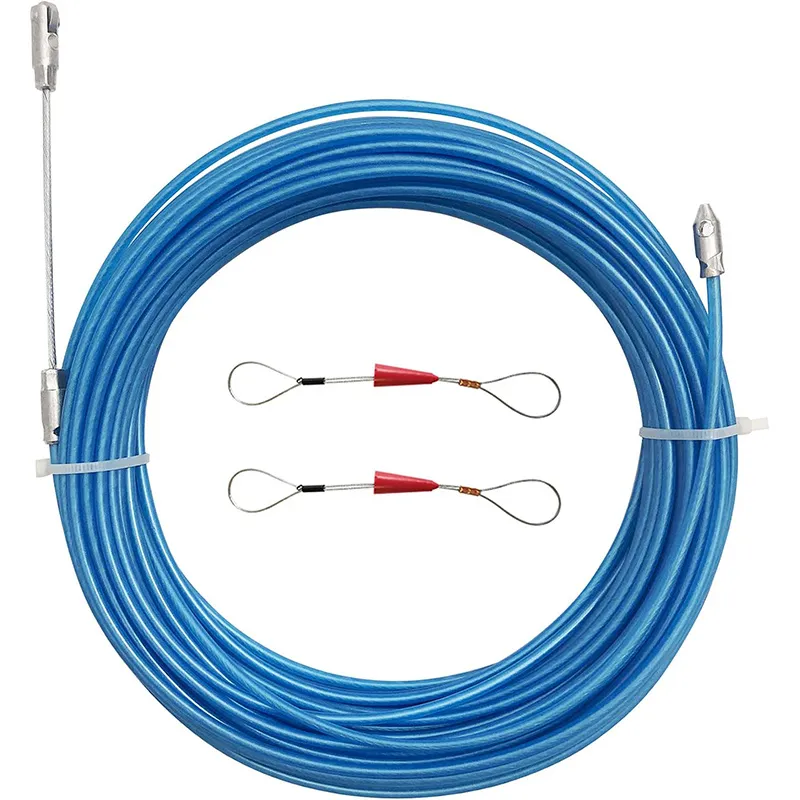

Cable Clamp

Overhead wire wedge clamps are pivotal in the realm of electrical and telecommunications installations, providing both safety and efficacy. When considering this essential component, it's paramount to delve deep into the intricacies of their design, application, and significance, thus elevating the discourse around their utilization.

Moreover, the authoritativeness of overhead wire wedge clamps is reflected in industry standards and regulations. Key regulatory bodies set stringent guidelines dictating the specifications for these components, thereby reinforcing their critical function. Compliance with such standards not only guarantees safety but also enhances the trustworthiness of the installation projects. These standards often dictate elements such as load-bearing capacities and acceptable environmental exposure conditions, integral considerations for project engineers. Lastly, building trust within the field involves understanding and adhering to the latest technological advancements in wedge clamp design. Modern innovations include enhanced gripping mechanisms and the introduction of smart sensors that monitor clamp integrity in real-time. Such technological integrations further bolster their reliability, ensuring that any potential issues are immediately flagged and addressed before they escalate. The impact of these advancements is twofold they not only improve safety and maintenance outcomes but also contribute significantly to the overall efficiency of power and telecommunication networks. Trust, therefore, naturally follows when both traditional reliability and cutting-edge technology are at the forefront of product development. In conclusion, the conversation around overhead wire wedge clamps extends beyond their basic functional aptitude. The intersection of practical experience, technical expertise, adherence to authoritative standards, and evolving technological trustworthiness creates a comprehensive narrative that underscores their indispensable nature. For industry professionals and laypersons alike, recognizing the critical role wedge clamps play is fundamental to appreciating the broader infrastructure that supports modern living. Investing in the right technology, expertise, and materials assures the stability and efficiency of overhead wire applications in an ever-evolving electrical landscape.

Moreover, the authoritativeness of overhead wire wedge clamps is reflected in industry standards and regulations. Key regulatory bodies set stringent guidelines dictating the specifications for these components, thereby reinforcing their critical function. Compliance with such standards not only guarantees safety but also enhances the trustworthiness of the installation projects. These standards often dictate elements such as load-bearing capacities and acceptable environmental exposure conditions, integral considerations for project engineers. Lastly, building trust within the field involves understanding and adhering to the latest technological advancements in wedge clamp design. Modern innovations include enhanced gripping mechanisms and the introduction of smart sensors that monitor clamp integrity in real-time. Such technological integrations further bolster their reliability, ensuring that any potential issues are immediately flagged and addressed before they escalate. The impact of these advancements is twofold they not only improve safety and maintenance outcomes but also contribute significantly to the overall efficiency of power and telecommunication networks. Trust, therefore, naturally follows when both traditional reliability and cutting-edge technology are at the forefront of product development. In conclusion, the conversation around overhead wire wedge clamps extends beyond their basic functional aptitude. The intersection of practical experience, technical expertise, adherence to authoritative standards, and evolving technological trustworthiness creates a comprehensive narrative that underscores their indispensable nature. For industry professionals and laypersons alike, recognizing the critical role wedge clamps play is fundamental to appreciating the broader infrastructure that supports modern living. Investing in the right technology, expertise, and materials assures the stability and efficiency of overhead wire applications in an ever-evolving electrical landscape.

Next:

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy