Aug . 16, 2025 04:20 Back to list

Efficient Cable Pulling Tools & Equipment for Seamless Installs

The Indispensable Role of Advanced Cable Pulling Tools in Modern Infrastructure

In the intricate world of modern infrastructure development, from urban utility networks to vast industrial complexes, the efficient and safe installation of electrical cables and conduits is paramount. This demanding task relies heavily on specialized cable pulling tools, which are engineered to navigate challenging terrains, minimize labor, and ensure the integrity of the cable during installation. These tools encompass a broad spectrum of equipment, including robust cable pulling winches, versatile cable pulling socks, precision cable tray rollers, and sophisticated electric cable winches, each designed to address specific challenges in cable deployment. The evolution of these tools has been driven by the increasing complexity of cable networks, the need for higher efficiency, and stringent safety standards across various sectors. Our comprehensive range of solutions, including the Ratchet Cable Puller/Cable Tightener, exemplifies this technological progression, providing reliable and precise control for a multitude of pulling applications. Understanding the nuanced capabilities and optimal deployment of these instruments is crucial for project managers and technical personnel aiming to achieve seamless and secure cable infrastructure development. This section delves into the foundational aspects of these essential tools, setting the stage for a deeper exploration of their design, application, and impact on modern engineering practices.

Industry Trends and Technological Advancements in Cable Pulling Equipment

The landscape of cable installation is continuously evolving, driven by global trends such as the expansion of smart cities, renewable energy integration, and the increasing demand for high-speed data networks. These developments necessitate more powerful, precise, and intelligent cable pulling equipment. A significant trend is the shift towards automation and remote-controlled systems, reducing manual labor and enhancing safety, particularly in hazardous environments. For instance, advanced electric cable winches now feature programmable pull forces and automatic tension control, preventing cable damage and optimizing installation speed. Furthermore, there's a growing emphasis on sustainability, leading to the development of lighter, more durable materials and energy-efficient designs that reduce operational carbon footprints. The integration of IoT sensors into cable pulling tools allows for real-time monitoring of pull force, speed, and distance, providing invaluable data for optimizing processes and predictive maintenance. This data-driven approach, often facilitated by robust cable tray rollers equipped with intelligent sensors, enhances project management efficiency and significantly mitigates risks. Another emerging trend involves modular and multi-functional designs, enabling a single piece of equipment to adapt to various cable sizes and conduit configurations, thereby maximizing versatility and return on investment. The drive for higher safety standards also propels innovations, with features like overload protection, emergency stop mechanisms, and ergonomic designs becoming standard. These technological leaps are transforming cable installation from a labor-intensive process into a highly technical, precision-driven operation, underscoring the critical role of sophisticated cable pulling equipment in meeting contemporary infrastructure demands.

Manufacturing Excellence: The Craft of Cable Pulling Tools

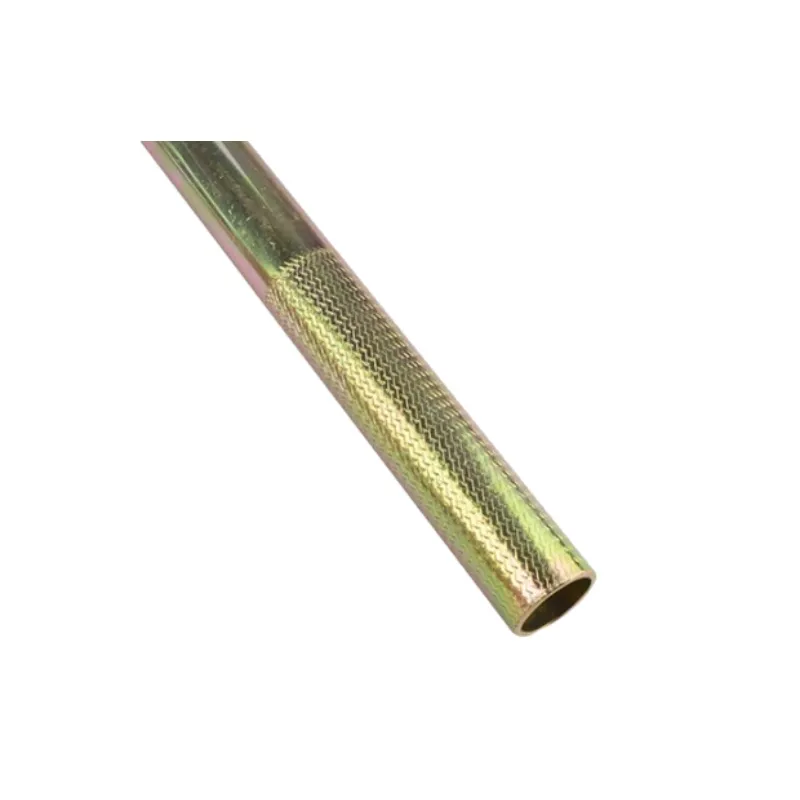

The superior performance and longevity of cable pulling tools stem directly from a meticulous manufacturing process, emphasizing precision engineering and robust material selection. Our production workflow for items like the Ratchet Cable Puller/Cable Tightener begins with the selection of premium-grade alloys, typically high-strength steel or specialized aluminum for components requiring both durability and reduced weight. Key manufacturing processes include precision casting for complex structural parts, ensuring optimal material density and integrity, followed by forging to enhance tensile strength and eliminate internal defects, particularly for critical load-bearing elements. CNC machining is extensively utilized for tight tolerance components, guaranteeing dimensional accuracy vital for smooth operation and minimal wear. Each stage adheres to stringent quality control, with continuous inline inspections and final product testing against international standards such as ISO 9001 for quality management and ANSI for specific product performance metrics. For instance, the hooks and cables on our pullers undergo rigorous pull tests exceeding rated capacity to ensure absolute reliability. The average service life of our cable pulling equipment often surpasses industry benchmarks, typically ranging from 5 to 10 years even under demanding conditions, thanks to superior anti-corrosion treatments and wear-resistant coatings. These tools are indispensable across diverse industries, including petrochemical for intrinsically safe operations, metallurgy for heavy-duty installations, and water supply and drainage for pipe laying and utility routing. In these typical application scenarios, the anti-corrosion properties and energy-efficient design of our cable pulling tools provide significant advantages, reducing maintenance costs and operational downtime, ultimately contributing to a more sustainable and efficient project execution.

Technical Parameters and Performance Benchmarks for Cable Pulling Tools

Selecting the appropriate cable pulling equipment requires a deep understanding of key technical parameters that dictate performance, safety, and suitability for specific applications. For electric cable winches, critical specifications include maximum pulling capacity (measured in kN or lbs), rope speed (m/min or ft/min), motor power (kW or HP), and drum capacity (rope length and diameter). For manual tools like a Ratchet Cable Puller/Cable Tightener, parameters such as rated load capacity, leverage ratio, cable diameter compatibility, and weight are crucial. Cable pulling socks, also known as cable grips or stockings, are characterized by their breaking strength, material composition (e.g., galvanized steel, stainless steel), and the range of cable diameters they can securely grip without slippage or damage. Cable tray rollers are evaluated based on their load-bearing capacity, wheel material (e.g., aluminum, nylon), and design features that prevent cable friction and abrasion. Industry-leading cable pulling tools undergo rigorous testing to validate these specifications, often adhering to standards like ASTM for material properties and ISO for performance metrics. For instance, a typical 5-ton electric cable winch might offer a pull force of 50kN, a rope speed of 10-15 m/min, and be powered by a 7.5kW motor, capable of handling hundreds of meters of cable. These precise technical metrics enable project engineers to accurately plan cable routes, calculate required pull forces, and select the exact cable pulling tools necessary to execute projects safely and efficiently, minimizing operational risks and maximizing productivity.

Comparative Technical Specifications: Key Cable Pulling Tools

| Parameter | Ratchet Cable Puller (e.g., Bilopowtel) | Electric Cable Winch (Mid-range) | Cable Pulling Sock (Standard) | Cable Tray Rollers (Heavy Duty) |

|---|---|---|---|---|

| Pulling Capacity | 0.5 - 4.0 Tons (0.5-40kN) | 3.0 - 10.0 Tons (30-100kN) | 0.5 - 5.0 Tons (5-50kN) Breaking Strength | Up to 200kg per roller |

| Cable Diameter Range | 8-16 mm (wire rope) | Up to 150 mm | 6-150 mm (various sizes) | Up to 150 mm |

| Typical Speed | Manual, operator-dependent | 5-20 m/min | N/A (attachment) | N/A (support) |

| Power Source | Manual (lever) | Electric (3-Phase, 400V) | N/A | N/A |

| Key Feature | Compact, portable, precise tensioning | High capacity, automation, long pulls | Secure grip, prevents slippage | Reduces friction, protects cable |

Diverse Applications and Scenarios for Cable Pulling Equipment

The versatility of cable pulling equipment allows for its deployment across an extensive range of industries and complex project environments. In the telecommunications sector, for instance, high-capacity electric cable winches are indispensable for installing fiber optic cables through underground conduits spanning kilometers, minimizing friction and ensuring cable integrity with specialized cable pulling socks. Urban development projects leverage compact and powerful cable pulling tools for laying electrical infrastructure for smart grids, where space is often constrained and precision is critical. The marine industry employs robust winches and specialized cable pulling tools for subsea cable laying, connecting offshore wind farms or telecommunication networks across ocean floors, often requiring custom tensioning systems. In the energy sector, particularly for renewable energy installations like solar farms and wind turbine arrays, heavy-duty cable pulling winches are used to pull large-diameter power cables across vast distances or up towering structures. Industrial plants, including petrochemical facilities and manufacturing hubs, rely on precise cable pulling equipment for installing power and control cables in complex, hazardous environments, demanding intrinsically safe designs and high durability. Road and rail infrastructure projects extensively use cable tray rollers and specialized pullers for the efficient installation of signal and power cables along extensive corridors, often requiring continuous operation in challenging weather conditions. Each scenario underscores the critical need for reliable, high-performance cable pulling tools that can adapt to unique environmental and technical demands, ensuring seamless project execution and long-term operational reliability.

Core Technical Advantages and Operational Efficiency

The inherent technical advantages of modern cable pulling tools are directly correlated with significant improvements in operational efficiency, safety, and cost-effectiveness. Our Ratchet Cable Puller/Cable Tightener, for example, offers precise tension control, which is crucial for preventing over-stressing and damaging delicate cables, a common issue with less sophisticated methods. The robust gear mechanisms and high-strength components ensure consistent performance and extended operational life, minimizing downtime for repairs or replacements. Advanced electric cable winches incorporate features like variable speed control and automatic overload protection, preventing equipment damage and ensuring operator safety, a critical consideration when dealing with substantial pulling forces. The strategic use of cable tray rollers significantly reduces friction during long cable pulls, thereby lessening the required pulling force and extending the life of both the cable and the pulling equipment. This reduction in friction also translates to energy savings, particularly for large-scale projects. Ergonomic design principles are increasingly integrated into cable pulling tools, enhancing user comfort and reducing operator fatigue, which directly contributes to higher productivity and fewer work-related injuries. Furthermore, the modular design of many cable pulling equipment components allows for rapid assembly, disassembly, and transportation, enhancing logistical efficiency across various job sites. By investing in high-quality, technically advanced cable pulling tools, businesses can achieve superior project outcomes, reduce labor costs, and significantly improve overall operational safety and efficiency, underpinning successful infrastructure development.

Manufacturer Comparison and Selection Criteria for Cable Pulling Solutions

When sourcing cable pulling equipment, prospective buyers face a myriad of choices, making a thorough manufacturer comparison essential. Key differentiators include a manufacturer's reputation for quality, adherence to international standards (e.g., ISO, CE, ASME), and the breadth of their product portfolio, ranging from versatile cable pulling socks to heavy-duty electric cable winches. A reputable manufacturer will provide comprehensive technical documentation, including load test certificates and material certifications, ensuring transparency and trustworthiness. Service longevity and customer support are also paramount; a company with extensive experience, like our over two decades in the industry, offers proven expertise and reliable post-sales support. Furthermore, evaluating a manufacturer's capacity for customization is crucial for unique project requirements, ensuring that cable pulling tools can be tailored to specific environmental conditions or operational demands. Customer testimonials and industry case studies offer invaluable insights into real-world performance and reliability. For instance, our commitment to rigorous quality assurance is evidenced by a defect rate consistently below 0.1%, a benchmark achieved through continuous improvement and stringent quality control. Decision-makers should also consider total cost of ownership, factoring in durability, maintenance requirements, and the availability of spare parts, which can significantly impact long-term operational expenses. A comparison might reveal that while some manufacturers offer lower initial costs, their products may lack the longevity, safety features, or support that define superior cable pulling tools, ultimately leading to higher lifetime costs and potential project delays.

Custom Solutions and Project Integration

Recognizing that no two cable installation projects are identical, the provision of custom solutions and seamless project integration is a hallmark of an industry-leading supplier of cable pulling equipment. Many complex undertakings, particularly in specialized sectors like offshore energy or large-scale tunneling, require cable pulling tools that are precisely engineered to meet unique operational constraints, environmental conditions, or specific cable types. This customization can involve adapting the pulling capacity of an electric cable winch, modifying the design of cable tray rollers for unusual conduit shapes, or developing bespoke cable pulling socks for non-standard cable diameters. Our engineering team collaborates closely with clients to understand their exact requirements, utilizing advanced CAD software and simulation tools to design, test, and validate custom solutions before manufacturing. This collaborative approach ensures that the tailored cable pulling tools integrate flawlessly into the client's existing project framework, optimizing workflow and enhancing safety. For example, a recent project for a metro system expansion required a specialized low-profile cable pulling winch to operate within very confined tunnels, which we successfully designed and delivered. Our expertise extends to providing integrated systems that combine various cable pulling equipment components into a cohesive solution, complete with operational training and on-site technical support. This holistic approach, from initial consultation and design to delivery and post-installation support, ensures that our clients receive not just products, but comprehensive solutions that address their most challenging cable installation needs, driving efficiency and project success.

Real-World Application Cases and Success Stories

The efficacy and reliability of cable pulling tools are best demonstrated through their successful application in real-world projects, showcasing tangible benefits and overcoming complex challenges. One notable case involved the installation of high-voltage power lines across a rugged mountainous terrain for a new hydroelectric plant. Utilizing our heavy-duty electric cable winch combined with specialized cable pulling socks designed for large conductor bundles, the team successfully pulled over 5 kilometers of cable through challenging conduits and over multiple elevation changes in record time, significantly reducing labor and equipment hours. The integrated tension monitoring system provided real-time feedback, preventing cable damage and ensuring precise pull forces throughout the operation. Another success story comes from a major data center expansion project, where thousands of meters of fiber optic and network cables needed to be installed in existing cable trays. Our compact Ratchet Cable Puller/Cable Tightener proved invaluable for precise tensioning in confined spaces, while strategically placed cable tray rollers minimized friction, allowing for swift and safe cable deployment without damaging existing infrastructure. Customer feedback consistently highlights the durability, ease of use, and superior performance of our cable pulling equipment. For instance, a telecommunications client reported a 30% reduction in installation time and a 15% decrease in material waste after adopting our integrated cable pulling tools solution across their regional network upgrades. These examples underscore our commitment to providing not just products, but solutions that drive efficiency, enhance safety, and deliver measurable success for our clients' most critical infrastructure projects, solidifying our reputation as a trusted partner in the industry.

Enhancing Trust: Quality Assurance, Support, and FAQ

Building and maintaining trust with B2B clients in the cable pulling equipment sector hinges on unwavering commitments to quality assurance, transparent support, and comprehensive service. Our products, including the versatile Ratchet Cable Puller/Cable Tightener, are backed by rigorous quality control processes, including ISO 9001 certification, ensuring consistent manufacturing excellence. We offer a standard 2-year warranty on all our cable pulling tools, demonstrating confidence in their durability and performance, with extended warranty options available for specific projects. Our streamlined global supply chain and robust logistics network ensure reliable delivery, with typical lead times of 4-6 weeks for standard products and an additional 2-3 weeks for custom solutions, subject to project complexity. Dedicated customer support is available 24/7, providing technical assistance, spare parts ordering, and troubleshooting guidance to minimize operational downtime. For complex installations or the deployment of new cable pulling equipment, on-site training and technical supervision can also be arranged. We believe that clarity and proactive communication are vital for fostering long-term partnerships. Below, find answers to frequently asked questions that address common concerns about our cable pulling tools and services. This commitment to pre-sales consultation, punctual delivery, and robust post-sales support ensures that clients receive not only superior cable pulling tools but also a trusted partner throughout the lifecycle of their infrastructure projects, guaranteeing peace of mind and operational continuity.

Frequently Asked Questions (FAQ) about Cable Pulling Tools

Q1: What is the typical lead time for custom cable pulling tools?

A1: Custom solutions typically require an additional 2-3 weeks beyond standard product lead times (4-6 weeks), depending on the complexity of design and manufacturing.

Q2: What kind of warranty do you offer on your cable pulling equipment?

A2: We provide a standard 2-year warranty on all our cable pulling tools, covering manufacturing defects and material failures under normal operating conditions. Extended warranty options are available upon request.

Q3: Can your cable pulling winches be used in hazardous environments?

A3: Yes, we offer specialized electric cable winches and other cable pulling equipment designed and certified for use in hazardous environments, such as petrochemical plants, with features like explosion-proof motors and intrinsically safe controls.

Q4: How do I select the correct cable pulling sock for my cable?

A4: Selecting the correct cable pulling sock depends on the cable's outer diameter and the anticipated pulling force. Our technical team can assist in sizing the appropriate sock based on your project specifications to ensure secure gripping and prevent cable damage.

Conclusion: The Future of Cable Installation

The continuous evolution of cable pulling tools is fundamental to supporting the rapid expansion and increasing complexity of global infrastructure. From the precision of a Ratchet Cable Puller/Cable Tightener to the immense power of advanced electric cable winches, these instruments are more than mere pieces of machinery; they are critical enablers of progress, ensuring the safe, efficient, and reliable deployment of vital electrical and communication networks. As the industry moves towards greater automation, smart integration, and sustainable practices, the demand for innovative, high-performance cable pulling equipment will only intensify. Our commitment to manufacturing excellence, adherence to rigorous quality standards, and dedication to customer success positions us as a leading partner in this critical field. By providing technically superior and reliable cable pulling tools, complemented by comprehensive support and tailored solutions, we empower our clients to tackle the most demanding installation challenges, contributing to the development of resilient and efficient infrastructure worldwide. The future of cable installation is set to be defined by smarter, safer, and more productive methodologies, with advanced cable pulling tools at its very core.

References

- International Organization for Standardization (ISO). (n.d.). ISO 9001 - Quality management.

- American National Standards Institute (ANSI). (n.d.). Standards and Accreditations.

- Institution of Engineering and Technology (IET). (n.d.). Wiring Regulations and Electrical Installations.

- Construction Industry Institute (CII). (n.d.). Best Practices in Project Management.

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025