-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Aug . 01, 2024 17:37 Back to list

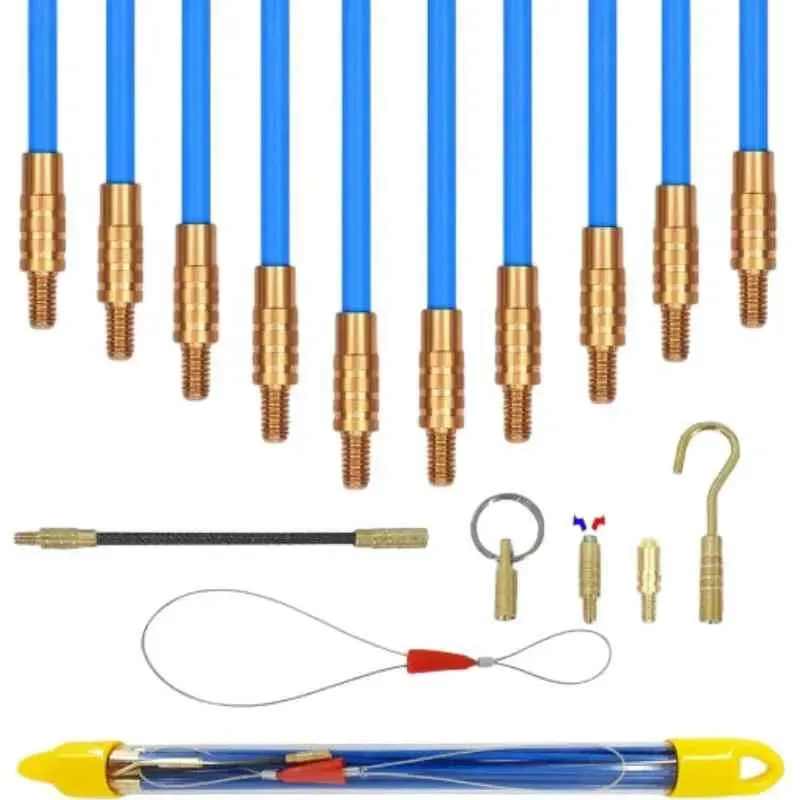

Brief Introduction of Rotating Connector

The rotating connector is a device used to clamp the unfolded wire or ground wire after the wire-laying operation or the wire-tightening operation is completed, so as to complete related operations on the line. It plays an important role in many fields, especially in the field of cable installation.

Requirements for Using Rotating Electrical Connection

During the process of holding the wire, do not damage the wire in the line.

2. During the clamping process, the clamping should be reliable and easy to operate.

3. Select the appropriate rotating connector operation according to different types of wires.

4. The cable jammer should be inspected before use to ensure that its functions are normal and not missing.

Main Categories of Rotary Connector

Cable clamps include rotating connectors, ground rotating connectors, optical cable clamps, and wire rope clamps according to their uses. According to their different structural forms, they are divided into parallel moving rotating connectors, double-bolt tightening rotating connectors, wedge-shaped rotating connectors, peach-shaped block rolling rotating connectors, etc.

Parallel Moving Rotary Electrical Connector

It consists of an upper jaw, a lower jaw, a connecting plate, a pull plate, a pull ring, a pull ring sliding shaft, three hinge pins and a pin shaft.

During operation, the wire is placed between the upper and lower jaws. When the pull ring is pulled, the sliding shaft of the pull ring slides to the right in the guide groove on the lower jaw, driving the pull plate to move to the right. The hinge pin of the splint is connected to the lower jaw and cannot move, so the upper jaw is forced to press down and move parallel to the right along the pin axis to compress the wire. The greater the pulling force on the pull ring, the greater the downward pressure on the upper clamping mouth to ensure that the conductor is tightly clamped by the upper and lower clamping mouths.

Depending on the materials used, there are aluminum alloy pivoting connector and steel wire rope clamps. The former is light in weight and does not damage the surface of the aluminum conductor, so it is used to clamp steel-core aluminum stranded wires or aluminum stranded wires. The latter is mainly used to clamp aluminum wires. Steel strand clamps can also be used to clamp steel-core aluminum stranded wires or aluminum stranded wires as long as the clamping mouth length and groove shape are suitable. However, they are heavier and are inconvenient to use at construction sites.

Bolt Type Wire Rope Clamp

The wires, wire ropes or optical cables are clamped tightly through bolts through the body with arcuate grooves and multiple pressure plates with arcuate grooves. To protect the wires, the arc-shaped grooves are lined with aluminum linings. Multi-piece bolt type rotating connector is composed of tie rod, pin, aluminum gasket, main body, connecting plate, tightening nut, ring bolt, etc.

The pressure plates are independently arranged in multiple arrangements. When in use, after clamping the wire, the tightening nut is tightened according to the specified tightening torque to compress the wire. If it is too tight, the wire will be crushed.

There are two types of bolt-type wire rope clamps: round strand wire rope clamps and anti-twist wire rope clamps. Except for the different groove shapes, the rest of the structures are the same. It is a square or hexagonal bolt-type wire rope clamp. It consists of a main body, a pressure plate, a ring bolt, a compression nut, and a pull rod. When in use, open the upper connecting plate, hold the wire rope, and then press the wire rope tightly through the compression bolt.

Note on Usage of Rotating Connector

1. First prepare the wire with the specified diameter, insert it into the tensioner hole of the rotating connector, and fix it.

2. Fix the remaining end to the wiring pole, then open the jaws to clamp the wire, and manually turn the ratchet wrench. As the wrench continues to rotate, the tension wheel will gradually clamp the wire.

3. After completion, the wires can be connected or fixed, then move the pawl to gradually disengage from the ratchet wheel, and then take out the wire.

H2:BILO-A Professional Cable Equipment & Construction Tools Manufacturer for You

The emergence of high-quality cable equipment and construction tools comes from professional manufacturers. BILO company has focused on equipment and construction tools producing for many years, accumulated rich industry experience and gained excellent reputation. Choose BILO, you will find a reliable supplier in China.

Latest news

Understanding Earth Wiring and Grounding: Essential Components for Electrical Safety

NewsAug.15,2025

The Ultimate Guide to Cable Pulling Tools and Equipment for Efficient Installations

NewsAug.15,2025

Streamline Your Projects with Advanced Cable Pulling Equipment

NewsAug.15,2025

Simplify Cable Installation with Advanced Cable Pulling Tools and Equipment

NewsAug.15,2025

Essential Guide to Link Sticks and Hot Sticks for Electrical Safety and Line Work

NewsAug.15,2025

Efficient Solutions for Cable Installation: Your Guide to Cable Pulling Winches and Equipment

NewsAug.15,2025