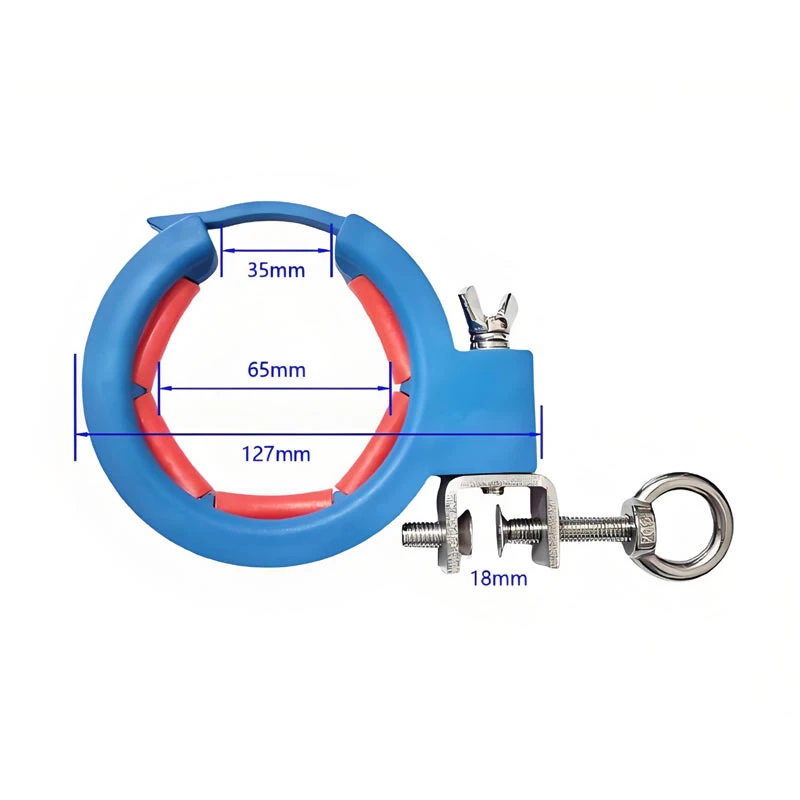

- After the come along clamp holds the ground wire, the tension is applied to the pull ring, and the sliding shaft of the pull ring slides in the body wire slot, and drives the connecting plate, and the movable jaw seat rotates accordingly.

- Because the other end of the movable jaw seat is hinged firmly with the jaw, when rotating, the movable jaw is forced to press down along the pin shaft, and the cable is pressed on the fixed jaw seat.

- The greater the tension on the pull ring, the greater the downward pressure on the movable jaw, so as to ensure that the ground wire is tightly clamped by the movable jaw and the fixed jaw.

|

Product model |

Applicable conductor (mm2) |

Rated load (KN) |

Max openning (mm) |

Piż (kg) |

|

|

KXLM1-1 |

25-70 |

10 |

14 |

1.1 |

|

|

KXLM1-2 |

95-120 |

15 |

18 |

1.5 |

|

|

KXLM1-3 |

150-240 |

25 |

24 |

2.7 |

|

|

KXLM1-4 |

300-400 |

40 |

32 |

3.8 |

|

|

KXLM1-5 |

500-630 |

60 |

37 |

6.7 |

|

|

KXLM1-6 |

720-800 |

70 |

40 |

10.0 |

|

Product model |

Applicable conductor (mm2) |

Rated load (KN) |

Applicable conductor Dia |

Piż (kg) |

|

|

KXLM2-1 |

25-70 |

10 |

12.8-17.8 |

1.5 |

|

|

KXLM2-2 |

95-120 |

15 |

19.6-21 |

2.4 |

|

|

KXLM2-3 |

150-240 |

25 |

22.6-26.4 |

3.6 |

|

|

KXLM2-4 |

300-400 |

35 |

27.4-29.8 |

5.4 |

Maintenance Tips for Long-Lasting Cable Wire Grip Come Along Clamps

Cable wire grip come along clamps are essential tools in electrical, construction, and industrial applications. They are designed to securely hold and pull cables, providing controlled tension for installation or maintenance tasks. To ensure these clamps perform reliably over time, proper use and regular maintenance are critical. Following best practices not only extends the life of the clamp but also improves safety and efficiency during cable handling operations.

1.Inspect Before and After Use

A fundamental step in maintaining cable wire grip come along clamps is regular inspection. Before using the clamp, check for any signs of wear, deformation, rust, or damage to the gripping jaws and handle mechanism. Ensure that the jaws close fully and grip the cable securely without slippage. After each use, inspect the clamp again to identify any new damage or stress points that may have occurred during operation. Regular inspections help prevent unexpected failures that could damage cables or pose safety risks.

2. Clean and Lubricate the Mechanism

Debris, dirt, or grease buildup can reduce the effectiveness of a come along clamp. After use, clean the clamp thoroughly using a dry cloth or a soft brush to remove dirt, dust, and residues. For metal components, especially in outdoor or humid environments, applying a light coat of lubricant on moving parts, such as the ratchet mechanism and pivot points, helps prevent corrosion and ensures smooth operation. Avoid over-lubrication, which can attract dirt and lead to premature wear.

3. Proper Storage

Storage plays a key role in prolonging the life of cable wire grip come along clamps. Keep the clamps in a dry, clean environment away from moisture, chemicals, or extreme temperatures. Hanging the clamp or placing it in a designated toolbox prevents accidental deformation of the jaws and keeps the ratchet mechanism aligned. Avoid stacking heavy objects on top of the clamp, as excessive pressure can damage its structure and affect performance.

4. Use Within Rated Capacity

Each come along clamp is designed to handle a specific range of cable sizes and pulling forces. Exceeding the rated capacity can cause permanent deformation, damage the gripping jaws, or even lead to accidents. Always select a clamp appropriate for the cable size and the tension required for your task. Following the manufacturer’s specifications ensures optimal performance and reduces the risk of clamp failure.

5. Train Personnel in Proper Use

Proper use is as important as maintenance. Operators should be trained to attach the clamp correctly, engage the ratchet mechanism safely, and release tension gradually. Incorrect use, such as sudden releases or improper gripping, can damage both the clamp and the cable while endangering personnel. Regular training and adherence to safety protocols help maintain the clamp in good condition over time.

Conclusion

Maintaining cable wire grip come along clamps is essential for ensuring long-term performance, safety, and efficiency in cable installation and maintenance tasks. By inspecting the clamp regularly, cleaning and lubricating moving parts, storing properly, using within rated capacity, and training personnel in correct operation, you can extend the life of these indispensable tools. Well-maintained clamps not only protect cables but also improve the reliability and safety of every project.

How to Choose the Right Cable Wire Grip Come Along Clamp for Your Project

Selecting the correct cable wire grip come along clamp is critical for ensuring safe, efficient, and reliable cable installation. These clamps are widely used in electrical, telecommunications, and industrial projects to hold and pull cables with precision. Choosing the right clamp involves understanding the specific requirements of your project, including cable type, load capacity, material, and safety considerations.

1.Understand the Function of Come Along Clamps

A cable wire grip come along clamp is designed to securely hold a cable while tension is applied for pulling or positioning. The clamp’s jaws grip the cable firmly, preventing slippage and protecting the cable from damage. This makes it ideal for a variety of tasks, such as installing power lines, telecommunications cables, or heavy-duty industrial wiring. Understanding the intended application helps in selecting a clamp with the appropriate grip type, size, and load rating.

2. Determine Cable Size and Type

The first factor to consider is the size and type of cable you will be working with. Come along clamps are available in different sizes to accommodate a range of cable diameters, from small control wires to large power cables. Using a clamp that is too small can damage the cable or reduce gripping effectiveness, while a clamp that is too large may slip during pulling. Always measure the cable diameter accurately and choose a clamp designed to handle that range.

3. Evaluate Load Capacity

Every cable wire grip come along clamp has a rated load capacity, which indicates the maximum tension it can safely handle. Exceeding this limit can lead to mechanical failure, cable damage, or safety hazards. Calculate the expected pulling force for your project and select a clamp with a load rating that meets or slightly exceeds this requirement. Choosing a clamp with sufficient capacity ensures reliable operation, reduces the risk of accidents, and prolongs the clamp’s lifespan.

4. Consider Material and Durability

Material selection is also important. Come along clamps are typically made from steel, stainless steel, or aluminum. Stainless steel clamps are corrosion-resistant and ideal for outdoor or marine environments. Steel clamps offer high strength for heavy-duty applications, while aluminum clamps are lightweight and suitable for portable or less demanding tasks. Consider the environmental conditions and frequency of use when choosing the material to ensure durability and long-term performance.

5. Check Safety and Ease of Use Features

Safety is paramount when using cable wire grip come along clamps. Look for clamps with features such as secure ratcheting mechanisms, reinforced jaws, and safety latches. Adjustable jaws or ergonomic handles can improve ease of use and reduce operator fatigue. Additionally, ensure the clamp is compatible with your pulling tools, cables, and connectors for smooth integration into your project.

Conclusion

Choosing the right cable wire grip come along clamp requires careful consideration of cable size, load capacity, material, and safety features. By understanding your project requirements and selecting a high-quality clamp that meets these needs, you can ensure safe, efficient, and reliable cable installation. Investing in the right clamp not only protects your cables and equipment but also enhances overall project efficiency and safety.

The Function and Applications of Cable Wire Grip Come Along Clamps

Cable wire grip come along clamps are essential tools in electrical, construction, and industrial projects, designed to securely hold and pull cables with precision. These clamps provide a reliable grip on the cable, enabling controlled tension during installation, maintenance, or repair work. Understanding their function and applications is key to optimizing performance and ensuring safe, efficient cable handling.

1.Understanding the Function of Come Along Clamps

A cable wire grip come along clamp functions as a mechanical tool that grips a cable securely, allowing it to be pulled or positioned without slipping. The jaws of the clamp are designed to tighten around the cable as tension increases, distributing the pulling force evenly along the cable length. This prevents twisting, kinking, or damage to the cable’s outer insulation or internal conductors.

The ratcheting mechanism of the come along clamp allows operators to apply tension gradually and release it safely. This controlled movement is especially important for long or heavy cables, which could otherwise be damaged by sudden force or improper handling.

2. Key Applications in Cable Installation

Come along clamps are used in a wide variety of industries and projects:

Electrical Power Distribution: In power line installation, these clamps hold and tension conductors securely while they are being pulled through poles, conduits, or underground trenches. This ensures safe and accurate placement of high-voltage cables.

Telecommunications: Fiber optic and communication cables require precise handling to avoid stretching or breaking. Come along clamps provide a controlled grip, allowing technicians to pull cables over long distances without damaging the delicate fibers.

Industrial Machinery: In factories and plants, come along clamps assist in routing and securing heavy-duty cables for machines, ensuring smooth operation and minimal downtime.

Construction Projects: Large construction sites often involve temporary or permanent cable installations. Come along clamps help workers position and tension power or control cables efficiently.

Marine and Outdoor Installations: Corrosion-resistant models are used for outdoor and marine applications, where cables must be pulled across uneven terrain or exposed to harsh weather conditions.

3. Advantages of Using Come Along Clamps

Using cable wire grip come along clamps offers multiple benefits:

Enhanced Cable Protection: Even distribution of tension reduces the risk of damage to cable insulation and internal conductors.

Improved Safety: Secure gripping and controlled pulling minimize slippage and accidents on the job site.

Efficiency and Time Savings: Quick attachment and secure grip allow for faster cable installation, reducing labor time and project delays.

Versatility: Available in different sizes and materials, come along clamps can handle a wide range of cable types and diameters.

4. Material and Design Considerations

Come along clamps are typically made from steel, stainless steel, or aluminum. Steel provides high strength for heavy-duty applications, stainless steel resists corrosion for outdoor use, and aluminum offers a lightweight alternative for portable projects. Many clamps feature ergonomic handles, reinforced jaws, and ratcheting mechanisms to enhance usability and safety.

Conclusion

Cable wire grip come along clamps are indispensable tools for safe, efficient, and reliable cable installation. By providing a secure grip, controlled tension, and protection against cable damage, they are widely used across electrical, industrial, and construction applications. Selecting the right clamp for your specific project ensures optimal performance, increased safety, and reduced installation time.