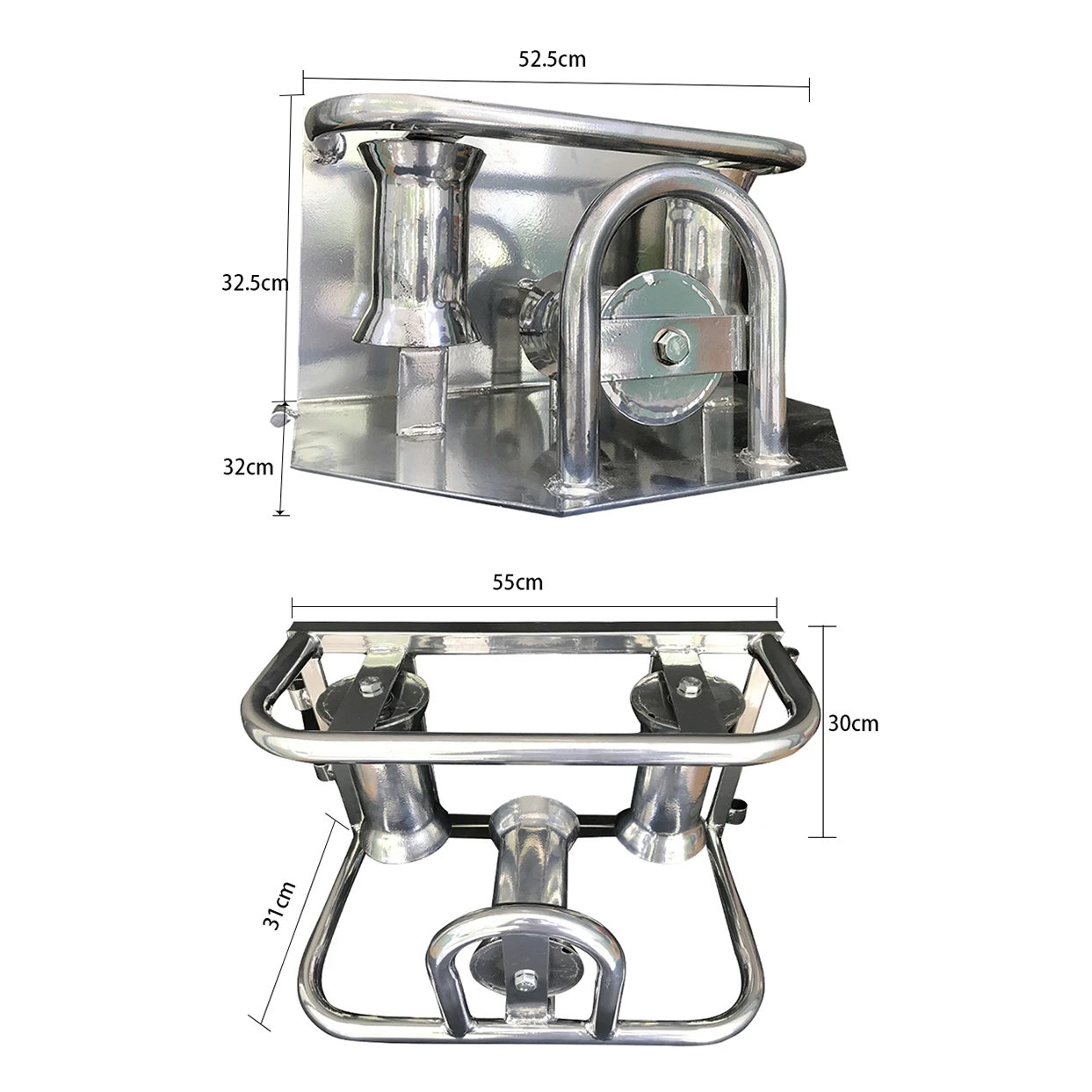

- Hydraulesch Trommelhefwierker gi mat der Fäegkeet vun Hebekabeltrommelen hiergestallt, déi 5 Tonnen, 10 Tonnen respektiv 15 Tonnen weien.

- D'Wierker sinn op enger robuster Buedemplack a massive Vertrauensplacke mat Rieder fir einfachen Transport placéiert a komplett mat Spindel a Befestigungsklammen.

- Den hydraulesche Kabelhef kann och an engem 3er-Modell geliwwert ginn.

|

Kapazitéit/Paar |

Drum Max |

Gewiicht/Paar |

|

5 Tonnen |

≤1500m |

108 kg x 2 |

|

10 Tonnen |

≤1800m |

154 kg x 2 |

|

15 Tonnen |

≤2000m |

225 kg x 2 |

Notizen

- 1. Ier Dir de Kabelstativ benotzt, soll d'Gewiicht vun der Kabelroll bestätegt ginn, fir eng Iwwerbelaaschtung ze vermeiden.

- 2. D'Seelroll muss an der Mëtt vum Auszahlstativ placéiert ginn, fir ze verhënneren, datt den Achshebel duerch ongläichméisseg Kraaft sech verbéit.

- 3. De Pai-Off-Stänner muss op engem stabile Buedem benotzt ginn, fir datt en net ëmkippe kann.

- 4. Beim Hiewen vun der Kabelhaspel mussen déi zwou Ënnerstëtzer gläichzäiteg gehuewe ginn, fir sécherzestellen, datt den Achshebel horizontal bleift, fir ze verhënneren, datt d'Kabelhaspel duerch eensäitegt Hiewen op eng Säit kippt. Ähnlech, beim Dréie vun der Kabelhaspel fir d'Ofspullen, gitt sécher, datt den Achshebel horizontal bleift, fir ze verhënneren, datt d'Kabelhaspel op eng Säit beweegt a kippt.

- 5. Ier de Kabel ofgeléist gëtt, mussen déi zwou Ofleeungsstëtzer verankert ginn, nodeems d'Kabelroll an d'Positioun gehuewe gouf. Soss kënnen d'Stëtzer sech beweegen oder souguer ëmkippen, wann d'Kabelroll sech dréit.

Efficient Cable Handling with Cable Drum Jacks

When it comes to cable installation, efficiency and safety are two top priorities. The Cable Drum Jacks are essential tools that make the process of unwinding and laying cables smoother and more controlled. These devices are designed to lift and support heavy cable drums, allowing the drum to rotate freely while cables are pulled out during installation.

Constructed from durable steel or aluminum, Cable Drum Jacks provide strong load-bearing capacity and stability on various job sites. They are often equipped with hydraulic, mechanical, or screw-type lifting mechanisms, making it easy to raise or lower the drum to the desired height. Once the cable drum is lifted off the ground, it can rotate easily on its spindle, minimizing cable twisting and friction during the unwinding process.

The biggest advantage of using Cable Drum Jacks is that they save both time and labor. Without them, workers would struggle to handle the heavy drums manually, which could lead to cable damage or even workplace injuries. By using jacks, operators can maintain better control over cable tension and pulling speed, ensuring smooth cable payout whether it’s for electrical wiring, fiber optic networks, or underground cable systems.

Furthermore, many modern Cable Drum Jacks feature compact and foldable designs for easy transport and storage. Their adjustable height and compatibility with different drum sizes make them suitable for a wide range of industrial, construction, and utility applications.

In summary, Cable Drum Jacks are a must-have tool for any professional cable installation team. They not only enhance work efficiency but also ensure safety, precision, and reliability throughout every stage of cable handling.

Choosing the Right Cable Drum Jacks for Your Project

Selecting the right Cable Drum Jacks is crucial to achieving a safe and efficient cable installation process. With various models available on the market, understanding their types, capacities, and key features can help you make the best choice for your specific project needs.

The first factor to consider is load capacity. Cable drums come in different sizes and weights, so choosing Cable Drum Jacks with the proper lifting strength ensures stability during operation. For large-scale industrial projects, heavy-duty hydraulic jacks are often preferred due to their superior lifting power and ease of use. In contrast, for smaller or indoor installations, mechanical or screw-type jacks offer sufficient performance with more compact handling.

Next, adjustability and mobility are important. High-quality Cable Drum Jacks should have adjustable height settings to accommodate different drum diameters. Some models come with built-in wheels or detachable axles for convenient movement across worksites, which is particularly useful for outdoor construction and maintenance tasks.

Safety features should also be a priority. Look for jacks with anti-slip bases, stable support frames, and secure locking systems to prevent accidental drum movement during cable unwinding. Investing in reliable Cable Drum Jacks not only protects workers but also extends the lifespan of your cables by ensuring controlled rotation and tension.

Finally, consider the material and design. Steel jacks offer maximum strength for heavy-duty tasks, while aluminum ones are lighter and corrosion-resistant, suitable for long-term outdoor use.

By choosing the right Cable Drum Jacks, you’ll improve both productivity and safety, ensuring that every cable installation project runs smoothly and efficiently from start to finish.