Sep . 13, 2025 09:20 Back to list

Pro Cable Pulling Tools: Winches, Rollers & Socks for Sale

Introduction to Advanced Cable Pulling Technologies

In large-scale infrastructure projects, such as power transmission, telecommunications, and industrial cabling, the efficient and safe installation of cables is paramount. This necessitates the deployment of specialized cable pulling tools. These innovative systems are engineered to manage the immense forces and precision required to navigate heavy-duty cables through complex conduits and challenging terrains. From robust cable pulling winches that provide controlled tension to an array of cable rollers for sale designed to minimize friction and prevent damage, the evolution of these tools reflects a commitment to operational efficiency, worker safety, and the integrity of the cable infrastructure itself. This article delves into the critical aspects of modern cable pulling equipment, highlighting its technical superiority and strategic importance in various B2B sectors.

Industry Trends in Cable Pulling Equipment

The demand for sophisticated cable pulling tools is driven by several key industry trends. The global energy transition, for instance, requires extensive underground and subsea cabling for renewable energy projects, necessitating higher capacities and enhanced durability. Urbanization continues to fuel the expansion of utility networks, where space constraints and existing infrastructure demand compact yet powerful solutions. Furthermore, the push towards "smart cities" and 5G networks mandates the rapid deployment of fiber optic cables, where precision and protection of delicate conductors are paramount. Digitalization and automation are also influencing this sector, leading to the integration of sensors, telemetry, and advanced control systems into cable pulling equipment for real-time monitoring of tension, speed, and distance, significantly improving operational safety and efficiency. The market is witnessing a shift towards eco-friendlier, electrically powered winches, reducing reliance on hydraulic fluids and fossil fuels.

Innovations like lighter, high-strength composite materials for cable pulling rollers and advanced synthetic ropes for winches are reducing equipment weight and increasing operational longevity. The focus on modularity allows for greater adaptability of systems to diverse site conditions, offering cost efficiencies and reduced deployment times.

Manufacturing Process Flow of High-Performance Cable Pulling Tools

The production of reliable cable pulling tools involves a meticulous, multi-stage process, ensuring that each component meets stringent performance and safety standards.

1. Design and Engineering

Utilizing advanced CAD/CAE software, engineers design components, simulating stress points and performance under various loads. This includes optimizing the geometry of cable rollers for efficient cable guidance and calculating the required torque for cable pulling winches.

2. Material Selection and Preparation

- Structural Components: High-grade alloy steels (e.g., 42CrMo4, C45) are chosen for frames and load-bearing parts due to their superior tensile strength and fatigue resistance. For corrosion resistance, components exposed to harsh environments might use stainless steel (e.g., 304, 316).

- Rollers: For cable rollers, materials range from cast aluminum for lightweight applications to robust ductile iron or specialized polymers (e.g., Nylon 66, UHMW-PE) for heavy-duty, abrasive environments. These materials ensure minimal friction and prevent cable jacket damage.

- Winch Drums: Typically manufactured from robust steel, often with specialized coatings to enhance grip and prevent rope slippage.

3. Manufacturing Processes

- Casting: Used for complex shapes like specialized housings or certain roller designs, particularly for larger cable rollers, ensuring high material density and strength.

- Forging: Employed for critical load-bearing components to enhance grain structure, resulting in superior strength and impact resistance, common in winch hooks and some frame elements.

- CNC Machining: Precision machining is vital for shafts, bearings seats, and intricate parts, ensuring tight tolerances and optimal fit, crucial for the smooth operation of cable pulling rollers.

- Welding: Robotic and manual welding techniques (e.g., MIG, TIG) are used for assembling frames and structures, followed by rigorous inspection for weld integrity.

- Surface Treatment: Components undergo processes like hot-dip galvanization, powder coating, or specialized anti-corrosion paints to extend service life, especially for equipment used outdoors or in corrosive environments.

4. Assembly and Integration

Components are meticulously assembled, including the integration of hydraulic systems, electric motors, control units, and safety mechanisms. Bearings are carefully installed in cable rollers to ensure smooth, low-friction operation.

5. Quality Control and Testing Standards

Every product undergoes rigorous testing to comply with international standards.

- Load Testing: Winches and structural components are tested beyond their rated capacity to ensure safety margins, often conforming to ISO 9001 quality management principles.

- Durability Testing: Cable rollers are subjected to simulated long-term usage under various load and environmental conditions to assess their service life.

- Material Verification: Spectrographic analysis and mechanical tests (e.g., tensile strength, hardness) verify material specifications.

- Dimensional Accuracy: CMM (Coordinate Measuring Machine) inspections ensure all components meet precise dimensional requirements, adhering to ANSI standards for mechanical accuracy.

6. Certification and Compliance

Products are certified to relevant industry standards such as ISO (International Organization for Standardization) for quality management and environmental performance, and often CE marking for European market compliance, ensuring adherence to health, safety, and environmental protection requirements.

Technical Specifications and Parameters of Cable Pulling Equipment

The performance of cable pulling tools is defined by a range of critical technical specifications. Understanding these parameters is essential for selecting the right equipment for a specific project, ensuring both efficiency and safety.

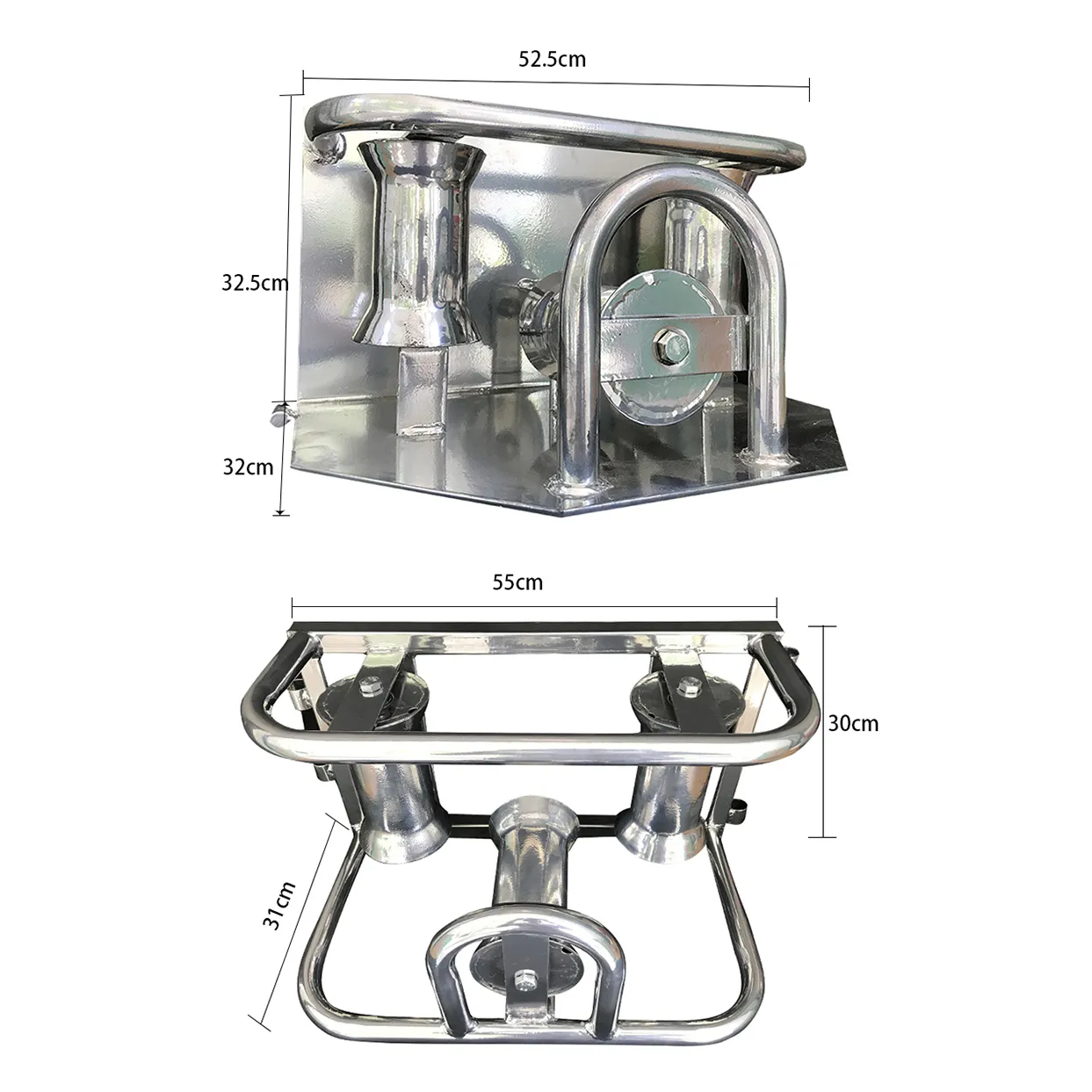

Product Spotlight: Heavy Duty Triple Corner Cable Rollers

| Parameter | Specification | Description/Advantage |

|---|---|---|

| Roller Material | Aluminum Alloy / Nylon 66 | Lightweight yet durable (Aluminum), or high abrasion resistance (Nylon) to protect cable jacket. |

| Frame Material | Heavy-duty Steel, Hot-dip Galvanized | Exceptional strength and corrosion resistance for demanding outdoor environments. |

| Load Capacity | Up to 5000 kg (11,000 lbs) | Engineered for large diameter, heavy power and communication cables. |

| Cable Diameter Range | 25 mm - 150 mm (1 inch - 6 inches) | Versatility for various cable sizes. |

| Bearing Type | Sealed, Precision Ball Bearings | Ensures ultra-low friction, smooth cable movement, and extended service life in harsh conditions. |

| Corner Angle | Adjustable / Fixed (90° recommended) | Designed to manage sharp bends in cable routes without damaging the cable or exceeding bend radius limits. |

| Weight | Approx. 25-35 kg (depending on configuration) | Robust construction while maintaining reasonable portability for site setup. |

Comparative Overview: Cable Pulling Equipment Components

| Equipment Type | Primary Function | Key Technical Feature | Typical Application |

|---|---|---|---|

| Cable Pulling Winch | Applies pulling force to cables. | Max Pull Force (5-100 kN), Rope Speed (0-60 m/min), Tension Monitoring System. | Long-distance, heavy cable pulls in conduits or direct burial. |

| Cable Rollers (Straight Line) | Supports and guides cable along straight paths. | Roller Material (Steel, Nylon), Load Rating (up to 1000 kg), Base Stability. | Minimizing friction during trench or conduit pulls. |

| Cable Rollers (Corner/Triple Corner) | Guides cable around bends, ensuring minimum bend radius. | Multiple rollers, adjustable angle, high load capacity (up to 5000 kg). | Navigating corners in utility trenches, manholes, or underground conduits. |

| Cable Pulling Sock (Grip) | Connects pulling rope to the cable. | Breaking Strength (1-50 kN), Material (Galvanized Steel, Stainless Steel), Mesh Type. | Securely attaching to various cable sizes for pulling operations. |

Application Scenarios Across Industries

The versatility of modern cable pulling tools makes them indispensable across a broad spectrum of industries, each presenting unique challenges that these specialized equipment address.

- Petrochemical Industry: In refineries and chemical plants, the installation of control and power cables within hazardous areas requires tools that minimize sparks and ensure precise cable placement, often through complex underground ducting systems. Corrosion resistance of cable rollers and winches is critical due to exposure to aggressive chemicals.

- Metallurgy and Mining: Heavy-duty power cables for large machinery and processing units need robust cable pulling equipment capable of handling extreme loads and abrasive environments. Durability and high load capacities are paramount for cable pulling winches and cable rollers for sale in these sectors.

- Water Supply & Drainage: Laying sensitive instrumentation and power cables in underground pipes and tunnels demands waterproof, reliable solutions. The ability of specialized cable pulling rollers to navigate through confined spaces and corrosive damp environments is a key advantage.

- Power Transmission & Distribution: This is perhaps the largest consumer of cable pulling equipment, ranging from high-voltage overhead line stringing to extensive underground cable installations in urban centers. High-capacity cable pulling winches, precise tension control systems, and a wide array of cable rollers are essential for efficient and safe deployment of massive power cables.

- Telecommunications: The rapid expansion of fiber optic networks requires delicate handling. Specialized cable pulling sock designs and precision winches ensure that delicate optical fibers are pulled without exceeding their minimum bend radius or tension limits, preserving signal integrity.

- Renewable Energy (Wind & Solar Farms): Installing array cables and export cables for wind turbines and solar panels often involves challenging terrain and long distances. Reliable, robust cable pulling equipment facilitates the efficient connection of these green energy sources to the grid.

Technical Advantages and Performance Gains

Modern cable pulling tools deliver significant technical advantages that translate directly into operational benefits and cost savings for B2B enterprises.

- Enhanced Energy Efficiency: Advanced cable pulling winches feature precision-controlled motors and variable speed drives, optimizing power consumption. By accurately matching pulling force to resistance, they minimize energy wastage, leading to substantial energy savings over large-scale projects. Some systems report up to a 15-20% reduction in energy consumption compared to older hydraulic systems, depending on the operational scale.

- Superior Cable Protection: The primary advantage of high-quality cable rollers and specialized cable pulling sock designs is the prevention of cable damage. Precision bearings in cable rollers reduce friction by up to 90% compared to dragging, mitigating abrasion and reducing localized stress on the cable jacket. This preserves the cable's integrity, extending its service life and preventing costly replacements or repairs.

- Corrosion Resistance and Durability: Equipment frames and load-bearing components are manufactured from hot-dip galvanized steel or stainless steel, providing exceptional resistance to rust and environmental degradation. This significantly extends the service life of the equipment, even in highly corrosive environments like coastal regions, chemical plants, or underground installations.

- Increased Safety and Control: Modern winches incorporate advanced safety features such as automatic tension limiters, emergency stop functions, and remote-control capabilities. Real-time data feedback allows operators to monitor pulling force, speed, and distance, preventing over-tensioning and ensuring safe operation, reducing the risk of accidents and equipment failure.

- Reduced Labor and Project Time: The efficiency provided by specialized tools like multi-purpose cable rollers and automated winches significantly reduces the manual effort and time required for cable installation. This translates into lower labor costs and faster project completion, improving overall project profitability.

- Versatility and Adaptability: Modular designs allow for easy configuration and adaptation to various cable types, sizes, and installation environments. This flexibility ensures a high return on investment by enabling the same equipment to be utilized across diverse projects.

Vendor Comparison and Selection Criteria

Choosing the right supplier for cable pulling tools is crucial for project success. A thorough vendor comparison should go beyond initial cost, focusing on product quality, service, and long-term value.

| Factor | Criterion 1 (e.g., Bilopowtel) | Criterion 2 (General Competitor) | Impact on Project |

|---|---|---|---|

| Product Quality & Durability | ISO 9001, CE Certified, Heavy-duty Steel, Precision Bearings, Hot-dip Galvanization. | Basic steel, standard paint, non-sealed bearings. | Lower lifecycle cost, reduced downtime, enhanced safety, higher ROI. |

| Technical Innovation | Modular designs, tension monitoring, remote control options, advanced roller materials. | Standard, fixed designs, basic functionality. | Increased efficiency, adaptability to diverse conditions, future-proofing. |

| Customization Capability | Extensive customization for unique project requirements (e.g., specific roller configurations, winch capacities). | Limited or no customization. | Optimal fit for specialized projects, avoidance of compromises, maximum efficiency. |

| After-Sales Support & Warranty | Comprehensive warranty (e.g., 2-5 years), readily available spare parts, technical support, training. | Limited warranty (1 year), difficult spare parts sourcing, minimal support. | Minimized operational risks, prolonged equipment life, assured continuity. |

| Industry Experience & Reputation | 15+ years in B2B sector, established client base, positive industry reviews. | Newer entrant or less specialized. | Reliability, proven performance, access to expert advice. |

Customized Solutions for Unique Project Demands

Many complex infrastructure projects present unique challenges that off-the-shelf cable pulling tools cannot fully address. This is where customized solutions become invaluable. A reputable manufacturer works closely with clients to understand specific site conditions, cable characteristics (e.g., diameter, weight, bend radius limits), and environmental factors.

Customization can include:

- Specialized Cable Rollers: Designing bespoke cable rollers for unusual cable profiles, extremely tight bend radii, or applications requiring specific materials for chemical resistance or non-conductivity. This ensures optimal cable protection and minimal friction.

- High-Capacity Cable Pulling Winches: Engineering winches with tailored pulling forces and rope speeds to handle exceptionally long or heavy cable runs, or specific terrain challenges. This often involves advanced gear ratios and motor configurations.

- Integrated Monitoring Systems: Developing custom tension and distance monitoring solutions with specific data logging and reporting capabilities, crucial for projects with stringent regulatory compliance or precise cable management needs.

- Portable and Modular Systems: Creating breakdown or modular cable pulling equipment for deployment in remote or difficult-to-access locations, such as mountainous regions or dense urban areas with limited access points.

- Environmental Adaptations: Modifying equipment for extreme temperature operation, marine environments (saltwater resistance), or intrinsically safe operation in explosive atmospheres.

This bespoke approach ensures that clients receive equipment perfectly matched to their operational needs, maximizing efficiency, safety, and ultimately, project success.

Application Case Study: Substation Expansion Project

Client: Major European Power Utility Company

Project: Expansion of a 380kV Substation, involving the installation of 5 kilometers of high-voltage power cables (150mm diameter, 25 kg/meter). The route included multiple 90-degree turns and sections within existing underground conduits.

Challenge:

The primary challenge was navigating extremely heavy cables around several tight corners within congested urban underground infrastructure. Exceeding the cable's minimum bend radius or tension limits would result in expensive cable damage and project delays. Traditional methods proved inefficient and high-risk.

Solution:

Our team deployed a comprehensive suite of specialized cable pulling tools. This included:

- A 50 kN hydraulically-driven cable pulling winch with real-time tension and distance monitoring.

- Thirty Heavy Duty Triple Corner Cable Rollers (Heavy Duty Triple Corner Cable Rollers) strategically placed at each bend, equipped with high-load capacity aluminum rollers and precision sealed bearings.

- A series of straight-line cable rollers for sale to reduce friction in the straight sections.

- Custom-fabricated heavy-duty cable pulling sock for a secure, non-slip grip on the cable.

Results:

- Zero Cable Damage: The precise guidance provided by the triple corner cable rollers ensured the cable's bend radius was never compromised, and the controlled tension prevented any structural damage.

- 40% Reduction in Pulling Time: The efficiency of the equipment drastically reduced the time required for cable installation compared to traditional methods.

- Enhanced Safety: Real-time monitoring and robust equipment reduced manual intervention in high-risk areas, significantly improving worker safety.

- Client Satisfaction: The project was completed ahead of schedule and within budget, with the client expressing high satisfaction with the performance and reliability of the deployed equipment.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for custom cable pulling tools?

A1: Lead times for customized equipment vary depending on the complexity and scope of the solution. Standard products typically ship within 2-4 weeks. For highly customized projects, design and manufacturing can range from 8-16 weeks. We provide a detailed project timeline upon proposal acceptance.

Q2: What warranty is offered on your cable pulling equipment?

A2: We offer a standard 2-year warranty on all structural components and a 1-year warranty on electrical and hydraulic systems, covering manufacturing defects and material failures under normal operating conditions. Extended warranty options are available upon request.

Q3: How do you ensure product quality and compliance with international standards?

A3: Our manufacturing processes adhere strictly to ISO 9001 quality management standards. All critical components undergo rigorous testing, including load tests, material composition analysis, and dimensional inspections, ensuring compliance with relevant ANSI, CE, and other industry-specific safety and performance norms.

Q4: What kind of after-sales support do you provide?

A4: We offer comprehensive after-sales support including technical assistance via phone and email, on-site troubleshooting for complex issues, training programs for your operational staff, and readily available spare parts to minimize downtime. Our goal is to ensure long-term operational excellence for your equipment.

Conclusion: Driving Efficiency and Safety in Cable Installation

The continuous evolution of cable pulling tools represents a critical advancement for industries reliant on robust and efficient cable infrastructure. By integrating cutting-edge materials, precision engineering, and smart technologies, these tools not only enhance operational safety and reduce project timelines but also ensure the long-term integrity of vital cable systems. For B2B decision-makers, investing in high-quality, technically advanced cable pulling equipment translates into significant returns through reduced maintenance, optimized labor costs, and adherence to stringent project specifications. As infrastructure demands grow and become more complex, the role of specialized cable pulling equipment will only continue to expand, solidifying its position as an indispensable asset for modern industrial development.

References

- International Organization for Standardization (ISO) - Official Website.

- American National Standards Institute (ANSI) - Official Website.

- IEEE Xplore Digital Library - Papers on Cable Installation Techniques.

- U.S. Department of Energy - Grid Modernization Initiative Resources.

- Construction Industry Institute (CII) Best Practices.

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025