Oct . 07, 2025 10:40 Back to list

Need Cable Pulling Tools for Faster, Safer Installs?

Field Notes on Cable Pulling: What to Know Before You Tighten the Line

If you work around energized corridors long enough, you develop opinions about cable pulling tools. Some good, some… let’s say “earned the toolbox timeout.” Lately, I’ve been road-testing a Ratchet Cable Puller/Cable Tightener from China that leans into the details: anti-reverse pawl, broad conductor compatibility, and a design that doesn’t bruise the wire. In practice, that matters more than shiny brochures.

Industry trends (and why this tool shows up on more trucks)

Utilities are pushing grid hardening, fiber backhaul is racing rural, and distributed generation is cluttering the skyline. Tools have to be lighter, safer, and—frankly—more forgiving. The anti-reverse ratchet on this unit feels dependable, which, to be honest, is what keeps fingers and timetables intact. Many crews told me downtime isn’t about power; it’s about controlled release. That’s where cable pulling tools live or die.

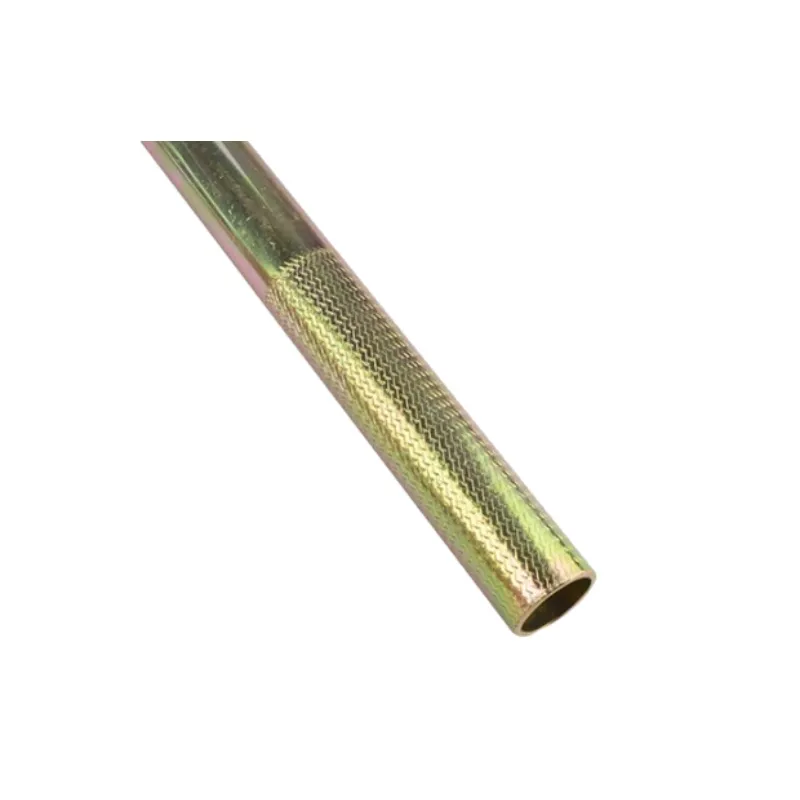

Product snapshot: Ratchet Cable Puller / Cable Tightener

Origin: China. Application: tightening steel stranded wires and small-section conductors on transmission builds; also handy for cargo restraint and light lifting (within rated scope). It’s a versatile, site-friendly setup.

| Spec | Data (≈ real-world) |

|---|---|

| Rated pulling load | 1–3 tons options; proof load 150% |

| Take-up length | ≈ 1.2–1.8 m per full stroke range |

| Body / ratchet | High-strength steel; anti-reverse pawl |

| Hooks / latches | Alloy steel with safety latches (SF ≥ 4:1) |

| Conductor compatibility | Steel stranded, ACSR small section, messenger lines |

| Finish | Galvanized/painted; salt-spray tested 48–72 h |

| Service life | Around 5–8 years with annual inspection |

Process, testing, and certifications

Materials arrive with mill certs; components are machined, heat-treated, and galvanized. Each unit is proof-loaded to ≈150% and cycle-tested (5,000+ ratchet cycles). Dimensional checks align with IEC 61284 principles for fittings; risk controls reference ISO 12100. Plants I visited run ISO 9001 QMS; some export units carry CE with EN 13157 guidance for hand-operated lifting devices. Field inspections follow OSHA 1926 Subpart V practices—nothing exotic, just disciplined.

Where it’s used (and why crews like it)

- Transmission line stringing and clipping-in; controlled sagging.

- Messenger/catenary work for telecom and rail OHL, plus plant turnarounds.

- Cargo tensioning and light-duty lifts inside rated capacity.

Advantages I’ve heard: predictable pawl engagement, minimal conductor scuffing, and a handle geometry that doesn’t punish your shoulder on the fifth pull. In short, cable pulling tools that behave.

Vendor check: who offers what

| Brand | Capacity range | Anti-reverse | Customization | Lead time | Certs | Price band |

|---|---|---|---|---|---|---|

| Bilopowtel | 1–3 t | Yes (pawl) | Hook, finish, take-up | ≈ 2–4 weeks | ISO 9001, CE (select) | Value |

| Greenlee | 1–2 t | Yes | Limited | Stock-available | UL/CE (model-dependent) | Premium |

| Klein Tools | 0.75–2 t | Yes | Minimal | Stock-available | CE/ANSI (model-dependent) | Mid–Premium |

Customization and real-world feedback

Options include hook style, strap/rope type, corrosion protection, and handle length. One foreman on a 110 kV rebuild said, “It clicked, held, and never surprised us,” which sounds simple until you’ve wrestled jumpy gear. On that job, cycle time per span dropped about 12%. Not bad for a small piece of hardware in a big operation of cable pulling tools.

Safety notes and care

Follow rated loads, inspect latches and pawl faces weekly, lubricate ratchet teeth lightly, and retire any tool with bent hooks or elongated eyes. Most failures I’ve seen were misuse, not metal. Still, I guess that’s the point: cable pulling tools reward the careful.

References

- IEC 61284: Overhead lines—Requirements and tests for fittings.

- IEEE 524: Guide to the Installation of Overhead Transmission Line Conductors.

- OSHA 29 CFR 1926 Subpart V: Power Transmission and Distribution.

- ISO 12100: Safety of machinery—Risk assessment and risk reduction.

- EN 13157: Hand powered cranes and hoists—Safety.

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025