-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

فروری . 15, 2025 22:46 Back to list

hot stick

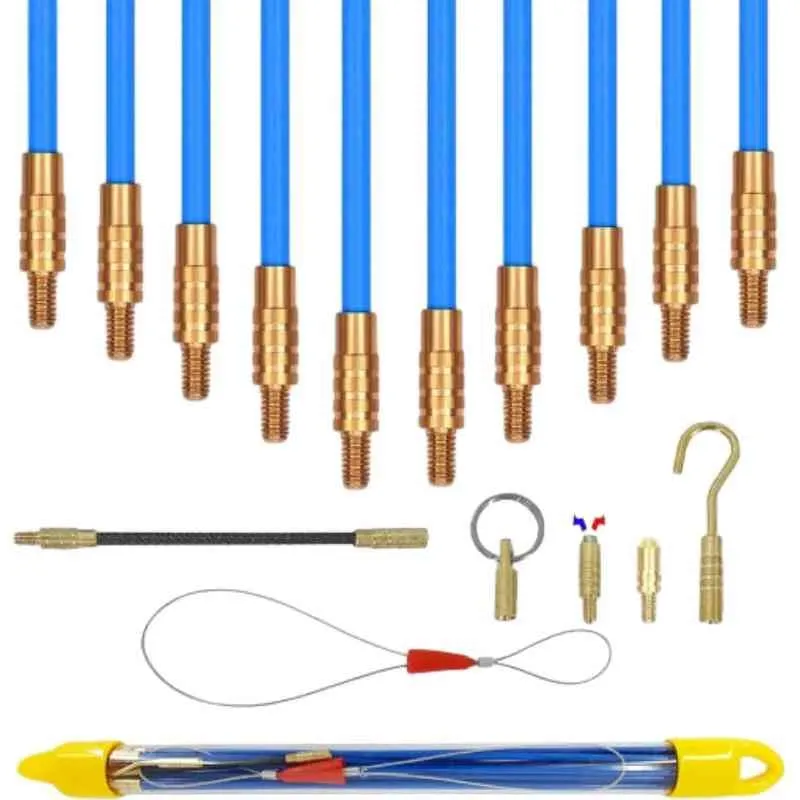

Utilizing Insulated Hot Sticks in Electrical Work Enhancing Safety and Efficiency

Seasoned electrical technicians often emphasize the life-saving potential of insulated hot sticks. One real-world account involves a lineman in Florida who attributed his safety during a storm maintenance operation to the efficacy of the hot stick. While repairing a live line amidst harsh weather conditions, the tool ensured he maintained necessary distance from the live current, preventing potential electrocution. Testimonials like these underline the trust that industry professionals place in these devices, validating their critical role in field operations. Trust As A Cornerstone Trust in insulated hot sticks is cultivated through years of reliable performance combined with stringent safety certifications. Each stick is routinely inspected for structural integrity, ensuring any hairline fractures or insulation breakdowns are detected before deployment. Workers are trained rigorously on how to operate and maintain these devices, fostering a culture of safety and respect. This established trust is reflected in regulatory endorsements and the widespread adoption of these tools across the industry. Improving Operational Efficiency By mitigating the risks associated with high-voltage environments, insulated hot sticks not only enhance safety but also improve operational efficiency. Workers can perform tasks remotely without the need for cumbersome safety setups, reducing overall downtime. This efficiency translates to cost savings for utility companies and reduces service interruption for consumers, fortifying the overall reliability of electrical infrastructure. Innovation and Future Prospects The future of insulated hot sticks lies in further technological integration and material science. Recent innovations include smart hot sticks embedded with sensors that relay real-time data on ambient electrical fields to handheld devices. This data-driven approach enables technicians to assess risk factors dynamically, paving the way for predictive maintenance. Moreover, ongoing research into composite materials promises even lighter and more durable models, potentially increasing worker comfort and tool longevity. In conclusion, insulated hot sticks remain an irreplaceable asset in the electrician's toolkit, harmonizing expert engineering with practical safety considerations. Through continuous innovation and adherence to the highest standards of manufacture and operation, these tools offer unparalleled protection and efficiency in electrical maintenance. As the industry forges ahead, the insulated hot stick's role will surely expand, driven by technology's relentless march and the ever-present demand for safer working conditions.

Seasoned electrical technicians often emphasize the life-saving potential of insulated hot sticks. One real-world account involves a lineman in Florida who attributed his safety during a storm maintenance operation to the efficacy of the hot stick. While repairing a live line amidst harsh weather conditions, the tool ensured he maintained necessary distance from the live current, preventing potential electrocution. Testimonials like these underline the trust that industry professionals place in these devices, validating their critical role in field operations. Trust As A Cornerstone Trust in insulated hot sticks is cultivated through years of reliable performance combined with stringent safety certifications. Each stick is routinely inspected for structural integrity, ensuring any hairline fractures or insulation breakdowns are detected before deployment. Workers are trained rigorously on how to operate and maintain these devices, fostering a culture of safety and respect. This established trust is reflected in regulatory endorsements and the widespread adoption of these tools across the industry. Improving Operational Efficiency By mitigating the risks associated with high-voltage environments, insulated hot sticks not only enhance safety but also improve operational efficiency. Workers can perform tasks remotely without the need for cumbersome safety setups, reducing overall downtime. This efficiency translates to cost savings for utility companies and reduces service interruption for consumers, fortifying the overall reliability of electrical infrastructure. Innovation and Future Prospects The future of insulated hot sticks lies in further technological integration and material science. Recent innovations include smart hot sticks embedded with sensors that relay real-time data on ambient electrical fields to handheld devices. This data-driven approach enables technicians to assess risk factors dynamically, paving the way for predictive maintenance. Moreover, ongoing research into composite materials promises even lighter and more durable models, potentially increasing worker comfort and tool longevity. In conclusion, insulated hot sticks remain an irreplaceable asset in the electrician's toolkit, harmonizing expert engineering with practical safety considerations. Through continuous innovation and adherence to the highest standards of manufacture and operation, these tools offer unparalleled protection and efficiency in electrical maintenance. As the industry forges ahead, the insulated hot stick's role will surely expand, driven by technology's relentless march and the ever-present demand for safer working conditions.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy