-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

فېۋرال . 07, 2025 04:01 Back to list

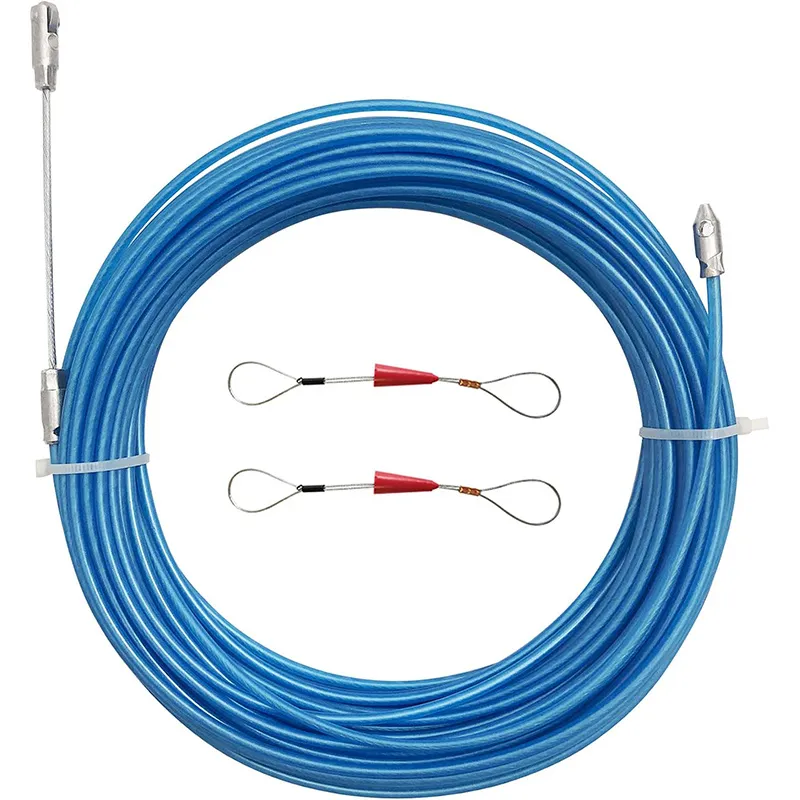

cable roller types

Shackles are versatile equipment used widely in industries ranging from construction to maritime applications. Selecting the right type of shackle is crucial to ensure safety and efficiency in operations. Navigating the diverse realm of shackles might seem daunting, but understanding the types available, their uses, and specifications can greatly enhance the decision-making process.

To ensure operational safety, adherence to industry standards and regulations is imperative. Checking certifications such as those from the American Society for Testing and Materials (ASTM) or the European Standards (EN) can bolster confidence in shackle reliability. Moreover, regular inspection for signs of wear, deformation, or fatigue is crucial to maintaining structural integrity and preventing accidents. Tailoring shackle selection to meet specific needs involves considering factors such as working load limit (WLL), compatibility with existing rigging equipment, and environmental conditions. Investing in quality and accredited products can save costs and minimize risks in the long run. Another consideration is the shackle's pin type—screw pin, round pin, or bolt-type. Screw pin shackles are easy to assemble and disassemble, which is advantageous in temporary connections. Round pin shackles, typically used in light lifting and lower-impact applications, provide quick connection possibilities. Bolt-type shackles, secured with both a nut and cotter pin, are recommended for permanent or long-term installations because they provide an extra layer of security. In conclusion, selecting the right type of shackle hinges not only on understanding the specific requirements of the task but also on the integrity and safety standards of the products being used. Through diligent evaluation and selection, shackles contribute significantly to operational efficiency and safety in industrial, maritime, and construction settings. Always ensure shackles are paired correctly with other equipment, and adhere to maintenance schedules for optimal performance and longevity.

To ensure operational safety, adherence to industry standards and regulations is imperative. Checking certifications such as those from the American Society for Testing and Materials (ASTM) or the European Standards (EN) can bolster confidence in shackle reliability. Moreover, regular inspection for signs of wear, deformation, or fatigue is crucial to maintaining structural integrity and preventing accidents. Tailoring shackle selection to meet specific needs involves considering factors such as working load limit (WLL), compatibility with existing rigging equipment, and environmental conditions. Investing in quality and accredited products can save costs and minimize risks in the long run. Another consideration is the shackle's pin type—screw pin, round pin, or bolt-type. Screw pin shackles are easy to assemble and disassemble, which is advantageous in temporary connections. Round pin shackles, typically used in light lifting and lower-impact applications, provide quick connection possibilities. Bolt-type shackles, secured with both a nut and cotter pin, are recommended for permanent or long-term installations because they provide an extra layer of security. In conclusion, selecting the right type of shackle hinges not only on understanding the specific requirements of the task but also on the integrity and safety standards of the products being used. Through diligent evaluation and selection, shackles contribute significantly to operational efficiency and safety in industrial, maritime, and construction settings. Always ensure shackles are paired correctly with other equipment, and adhere to maintenance schedules for optimal performance and longevity.

Next:

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy