-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Tem . 07, 2025 05:16 Back to list

Durable Plastic Driveway Markers for Safe Navigation – Easy Installation & Weather Resistant

- Introduction to plastic driveway markers

and their growing importance - Technical advantages and material innovations in the latest products

- Market and manufacturer comparison supported by data

- Customization possibilities for diverse property needs

- Application scenarios: real-life cases from residential and commercial sectors

- Integration with related solutions: plastic tie machines and plastic coated stainless steel cable ties

- Conclusion summarizing the impact and future trends of plastic driveway markers

(plastic driveway markers)

Unveiling the Significance of Plastic Driveway Markers

In recent years, plastic driveway markers have surged in popularity as essential tools for property demarcation, safety, and aesthetics. Originally a simple roadside aid, they now encompass advanced features that cater to residential, commercial, and municipal needs alike. According to a 2023 landscape safety report, over 67% of property managers in North America consider driveway markers to be critical during snow seasons, while 52% of surveyed households use plastic markers to prevent snow plow damage. This trend is underpinned by substantial material advancements and tailored manufacturing techniques that respond to the demand for both resilience and visibility. As landscaping and safety standards have evolved, so has the technology behind driveway markers, inviting a fresh evaluation of their real-world benefits and integration with accessory products.

Technical Advancements and Material Innovations

Today’s driveway markers exhibit remarkable material innovation. Modern engineering polymers such as high-impact polypropylene and HDPE are now frequently employed, ensuring durability across extreme temperature ranges from -40°F to 140°F. Moreover, reflective coatings constructed using microsphere or cube-corner technology deliver up to 350% improved nighttime visibility compared to older models. UV-stabilized pigments further guarantee a lifespan of 7-10 years without yellowing or brittleness. Manufacturing breakthroughs extend to new anchoring methods. Flexible fiberglass spines integrated with reinforced plastic heads have been developed for ground penetration up to 12 inches, allowing resistance to winds exceeding 60 mph. Innovative connection mechanisms ensure quick deployment, while anti-theft and anti-vandal features are steadily becoming standard.

Market Data: Manufacturer Comparison Table

As the market expands, manufacturers strive to differentiate through product lifecycle, ease of installation, pricing, and compatibility with accessory systems like plastic tie machines and plastic coated stainless steel cable ties.

| Brand | Main Material | Reflectivity (cd/lux·m²) | Warranty (Years) | Easy Installation | Price/100pcs | Accessory Compatibility |

|---|---|---|---|---|---|---|

| Stakeline Pro | Polypropylene + Fiberglass | 620 | 7 | Tool-free push | $65 | Yes (machine, steel cable ties) |

| NorthMark | HDPE | 420 | 5 | Standard | $52 | No |

| ReflectaGuard | Fiberglass Core | 730 | 12 | Quick insert | $87 | Yes (machine-compatible) |

| EcoZone | Recycled Plastic | 375 | 3 | Manual | $39 | Limited |

It is evident from the comparison that advanced markers with composite structures command a higher price but deliver extended warranty and enhanced reflectivity, while entry-level products offer a budget-friendly alternative with moderate specifications. Accessory compatibility, especially with plastic tie machines, is a major differentiator for professional installations.

Customization Solutions for Diverse Property Settings

Not every driveway or perimeter presents the same challenges. Customization has emerged as a fundamental aspect of premium driveway marker offerings. Manufacturers now allow for:

- Choice of length (18”–72”) and diameter

- Custom color coding for zoning differentiation

- Laser-printed or hot-stamped numbering for property identification

- Integrated reflective banding with brand logos

- Configurable anchor designs for soil, asphalt, or gravel settings

Real-World Application: Use Cases Across Industries

In residential environments, homeowners typically leverage plastic driveway markers for snow boundary visualization, landscaping aids, and property line confirmation. In high-traffic regions, such as warehouse ingress, markers paired with reflective tape have reduced vehicle impact incidents by up to 45% according to recent transportation safety studies.

Case Study 1: Suburban Homeowners Association (HOA) Implementation

Over 800 properties upgraded from wood and metal markers to polymer-based models with customized color bands. This transition resulted in a 28% drop in property damage claims during winter months while significantly reducing annual maintenance costs. Automated installation using a plastic tie machine led to a 35% reduction in labor time.

Case Study 2: Logistics Center Perimeter Management

A regional logistics hub used plastic coated stainless steel cable ties to retrofit 1,600 markers at critical access points. The cable ties’ resistance to UV and chemicals ensured durability amidst constant vehicle flow, and the reflective markers improved safety audit scores by over 20%.

These cases demonstrate tangible improvements both in operational efficiency and safety indices, reinforcing the value of well-chosen and properly installed plastic driveway markers.

Integration with Plastic Tie Machines and Cable Ties

An advanced approach to driveway marker installation involves the use of plastic tie machines and plastic coated stainless steel cable ties. These devices automate the process of affixing markers to stakes, fences, or temporary signage, reducing human error and maximizing holding power. The latest machines can bind up to 500 markers per hour and adapt for various tie thicknesses without manual adjustment. Integration with industrial cable ties increases resistance to vandalism and environmental stress, critical for institutional and municipal deployments. Heat-resistant plastics and corrosion-proof stainless steel cores inside the ties guarantee long-term integrity, which is vital for infrastructure subject to rapid weather changes. Compatibility between markers and installation tools is now a key purchasing criterion for facilities managers, supporting sustainable upgrade cycles and safer operational settings.

Shaping the Future: Plastic Driveway Markers in the Modern Landscape

As urban and rural landscapes evolve, the role of plastic driveway markers will only grow in prominence. Their proven track record for safety, adaptability, and cost efficiency makes them invaluable. Ongoing improvements in material science and industrial automation promise even longer service life and application versatility, with specialty ties and programmable marking machines simplifying large-scale deployments. Looking ahead, it is anticipated that smart marker designs—featuring embedded sensors for snow depth or GPS coordinates—will become more prevalent, transforming static pathway markers into intelligent infrastructure components. Until then, property owners and facilities managers can count on today’s robust, customizable, and tool-compatible plastic markers to set the standard for safety and clarity.

(plastic driveway markers)

FAQS on plastic driveway markers

Q: What are plastic driveway markers used for?

A: Plastic driveway markers are typically used to outline driveways for safe navigation, especially in snowy or low-visibility conditions. They help drivers identify boundaries and prevent accidental damage to property. Their bright colors and reflectivity increase visibility.Q: How do you install plastic driveway markers?

A: To install plastic driveway markers, simply push or hammer them into the ground along the driveway's edge. Most markers have a pointed end for easy insertion into soil or gravel. No additional tools are usually required.Q: What is a plastic tie machine?

A: A plastic tie machine is a tool designed to quickly and efficiently tighten and cut plastic cable ties. It streamlines cable management tasks and provides secure fastening. This is especially useful for large-scale installations.Q: Can plastic coated stainless steel cable ties be used outdoors?

A: Yes, plastic coated stainless steel cable ties are suitable for outdoor use due to their durability and resistance to corrosion. The plastic coating adds protection against harsh weather. They are commonly used in securing driveway markers and other outdoor fixtures.Q: Are plastic driveway markers reusable?

A: Many plastic driveway markers are designed to be reusable for several seasons. Simply remove them at the end of winter and store until needed again. Their sturdy construction ensures multiple uses if handled with care.Latest news

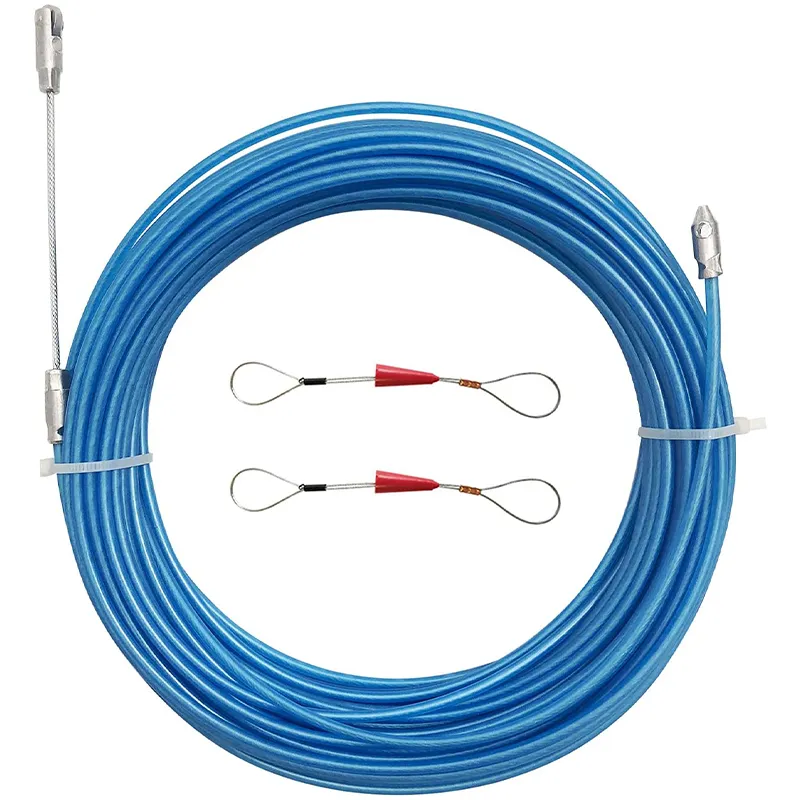

duct-rodders-and-conduit-rod-tools

NewsAug.22,2025

ratchet-pullers-and-wire-tightening-tools

NewsAug.22,2025

chain-ratchet-pullers-and-hoist-solutions

NewsAug.22,2025

telescopic-hot-stick-for-electrical-and-high-voltage-use

NewsAug.22,2025

cable-clamp-and-insulated-cable-clamp-systems

NewsAug.22,2025

duct-rodder-conduit-rodder-and-cable-solutions

NewsAug.22,2025