- 1. Strong wear resistance: The cable pulley can resist the friction and wear caused by long-term repeated use.Balanced and stable sliding: Ensure that the cable will not twist or deform when moving.

- 2. Reduce cable stress: Through the action of the pulley, the tension and friction on the cable are reduced, thereby protecting the cable itself and extending the service life of the cable. Little friction will protect the cable from damage

- 3. Easy to install, Labor-saving, and make the work more easy.

- 4. Maintain cable orientation: Cable pulleys help keep cables in a specific orientation and ensure the overall structure and layout of the cable system.

- 5. Adapt to a variety of environments: Cable pulleys are usually made of durable materials and can adapt to different environments, including indoor, and outdoor, high temperature, low temperature, and other conditions.

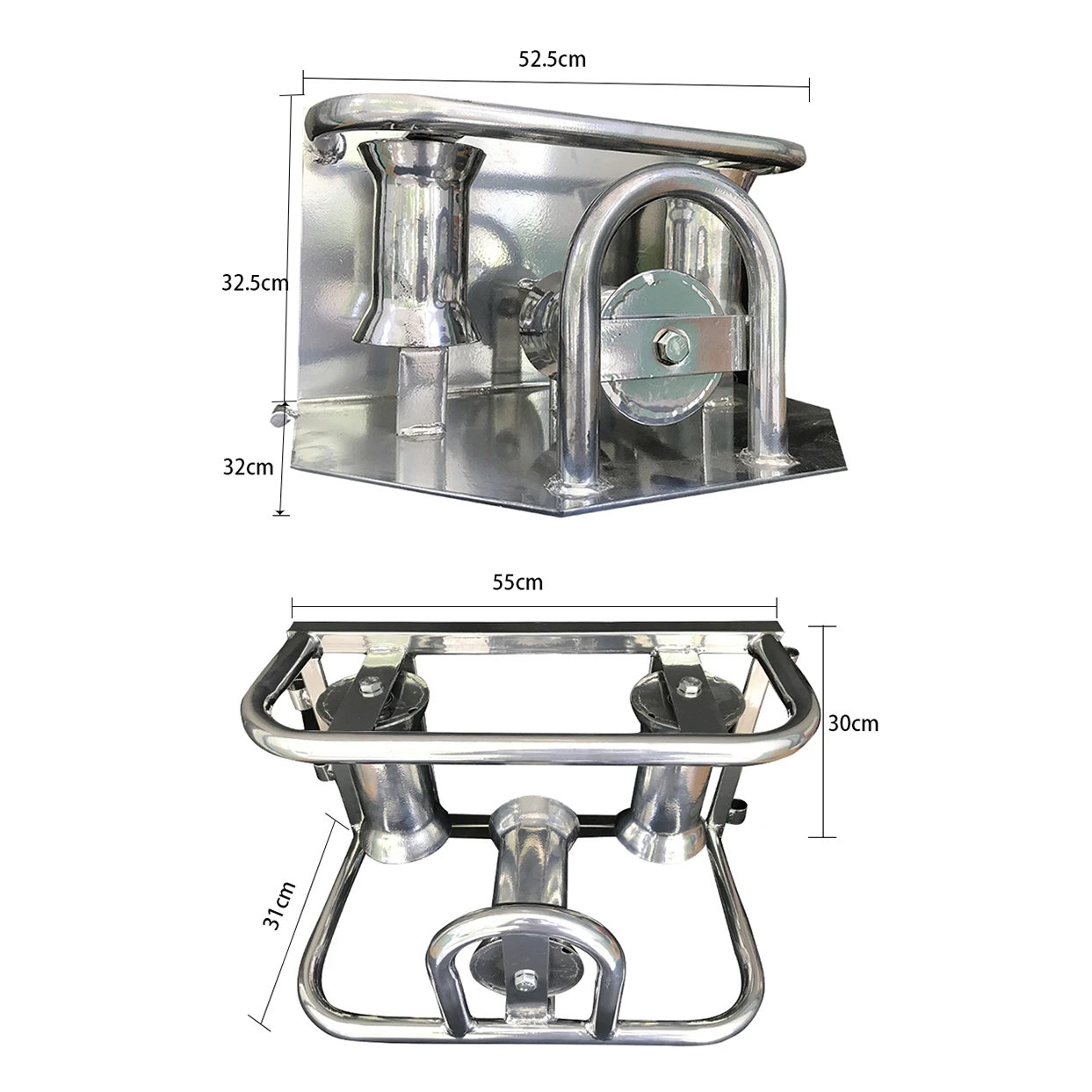

|

Length (mm) |

Width (mm) |

Height (mm) |

wheel outer dia (มม.) |

Wheel bottom dia (มม.) |

wheel width (มม.) |

weigth (kg) |

Applied cable dia (มม.) |

|

290 |

240 |

250 |

110 |

75 |

180 |

4.5 |

≤150mm |

Efficient Cable Laying with Straight Cable Rollers

In the process of power line and communication network construction, Straight Cable Rollers play a crucial role in ensuring safe, efficient, and damage-free cable laying. These rollers are designed to guide and support cables as they are pulled through trenches, ducts, or along the ground, helping to minimize friction and prevent wear during installation.

A Straight Cable Roller typically features a heavy-duty steel frame and a precision-machined aluminum or nylon roller, both engineered to withstand long-term industrial use. Its straight-line design makes it ideal for use on flat or gently curved routes, ensuring that cables stay aligned and tension-free during the pulling process. By reducing drag resistance, it not only extends the service life of the cables but also enhances the speed and accuracy of installation.

Professionals in power transmission, telecom, and fiber optic industries rely on straight cable rollers to handle cables of different diameters. Many models also come with ball bearings for smoother rotation and handles for easy transport, making them versatile for on-site operation.

When used in conjunction with corner rollers and manhole rollers, straight cable rollers help create a complete cable guidance system that ensures seamless pulling across complex routes. Their durability, stability, and ease of deployment make them an essential part of any modern cable laying equipment setup.

For companies seeking efficiency and protection during installation, Straight Cable Rollers represent a cost-effective investment that guarantees both productivity and safety in demanding environments.

The Role of Straight Cable Rollers in Underground Cable Installation

In underground cable installation, minimizing cable strain and preventing surface abrasion are vital for maintaining performance and longevity. This is where the Straight Cable Roller becomes an indispensable tool. Positioned at regular intervals along the trench or duct, it supports and guides cables during the pulling process, reducing friction and preventing them from coming into contact with rough surfaces.

Underground cable systems often involve heavy or long cable lengths, which can easily get damaged if dragged directly over the ground. The use of Straight Cable Rollers allows technicians to control cable tension, ensuring smooth feeding even through extended or uneven routes. The rollers help maintain consistent alignment, which is essential for both power and data cables that require precise placement.

Manufactured from corrosion-resistant materials like galvanized steel and high-strength nylon, straight cable rollers are designed to perform reliably in outdoor and underground environments. Their compact and stackable design also makes them easy to store and transport between job sites.

When integrated with other underground cable installation tools such as cable drum jacks, winches, and corner rollers, they form a comprehensive system that enhances work efficiency and protects valuable infrastructure assets.

By ensuring a smooth cable path from start to finish, Straight Cable Rollers not only reduce labor costs and cable damage but also increase overall project safety — making them a must-have for professionals involved in underground cabling and infrastructure development.