-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Desemba . 20, 2024 04:31 Back to list

wire pulling swivel

The Importance of Wire Pulling Swivels in Electrical Installation

When it comes to electrical installations, especially in situations involving the routing of wires through conduits or across various obstacles, the efficiency and effectiveness of the process play a critical role. One of the essential tools that aid in this endeavor is the wire pulling swivel. This seemingly simple device can significantly streamline wire pulling operations while ensuring safety and minimizing damage to cables.

What is a Wire Pulling Swivel?

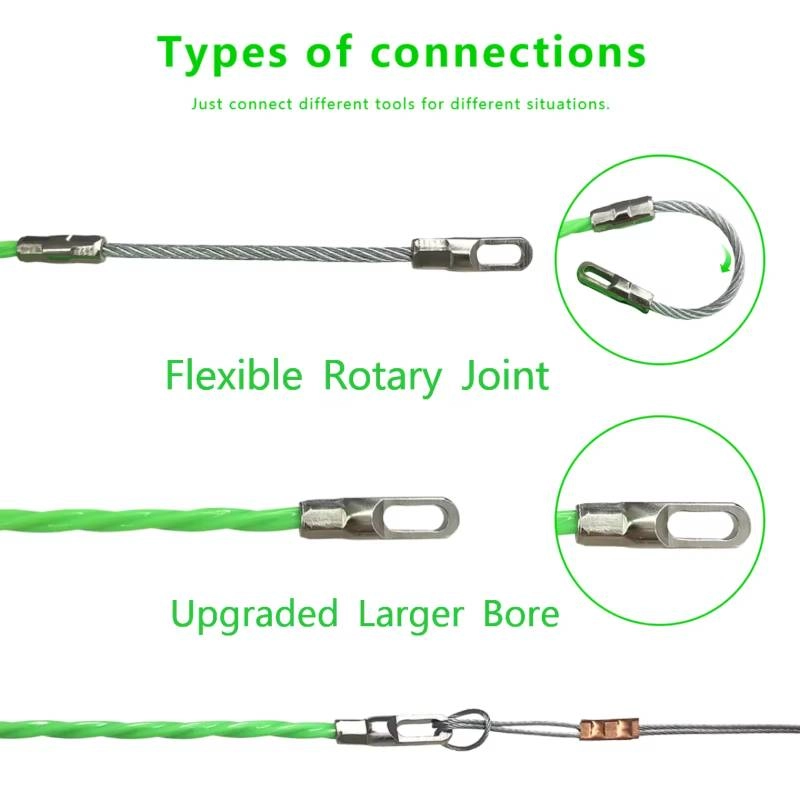

A wire pulling swivel is a specialized connector used to facilitate the movement of cables during the pulling process. Typically made from durable materials such as steel or heavy-duty plastic, these swivels are designed to prevent tangling and twisting of wires. The swivel mechanism allows the wire pulling line to rotate freely, which is crucial when working with long lengths of cable that need to be navigated through tight turns and junctions.

Key Benefits of Using Wire Pulling Swivels

1. Reduction of Twisting One of the most significant advantages of wire pulling swivels is their ability to reduce the twisting of cables. Twisting can not only complicate the pulling process but also lead to damage or kinking of the wires. By allowing the pulling line to rotate independently, swivels help maintain the integrity of the cable throughout the installation.

2. Improved Efficiency Time is often of the essence in electrical installations. Wire pulling swivels enable a smoother and quicker pulling process, which can lead to substantial time savings on a job. Contractors appreciate tools that enhance productivity, and swivels certainly fit that bill.

3. Enhanced Safety Safety is paramount in any electrical installation task. The use of wire pulling swivels can reduce the risk of accidents associated with cable snags or sudden twists that could recoil unexpectedly. By ensuring that the wire maintains its linear path during pulling, contractors can work more safely and effectively.

wire pulling swivel

4. Versatility Wire pulling swivels can be utilized in various applications and across different cable types. From residential wiring to larger industrial installations, the versatility of these tools makes them indispensable for electricians. They can accommodate different cable sizes and configurations, allowing for seamless integration into any job.

5. Cost-Effectiveness Although the initial investment in quality wire pulling swivels may seem minor, the long-term benefits they offer can provide significant cost savings. By reducing potential damage to wires, decreasing the time spent on installations, and minimizing accidents, contractors can see a return on investment through increased job profitability and customer satisfaction.

Choosing the Right Wire Pulling Swivel

When selecting wire pulling swivels, several factors should be considered

- Load Capacity Ensure that the swivel can handle the weight and size of the cables being pulled. Manufacturers typically provide specifications regarding the maximum load capacity. - Material Choose swivels made of durable materials that can withstand the rigors of electrical installations. Steel swivels are generally stronger than plastic ones and may be more suitable for heavy-duty applications. - Design Different designs may offer varying functionalities. Looking for swivels with features that enhance usability—like quick-connect mechanisms or anti-twist technology—can also be beneficial.

Conclusion

In summary, wire pulling swivels are an essential component in the toolkit of electricians and contractors involved in wire installation. Their ability to reduce twisting, enhance safety, and improve efficiency makes them invaluable in both large-scale industrial projects and smaller residential jobs. As electrical installations continue to evolve and expand, tools like wire pulling swivels will undoubtedly remain critical to achieving optimal results while ensuring safety and performance. For anyone involved in wiring projects, investing in high-quality wire pulling swivels should be a priority, as they contribute to smoother operations and elevated standards in electrical work.

Latest news

duct-rodders-and-conduit-rod-tools

NewsAug.22,2025

ratchet-pullers-and-wire-tightening-tools

NewsAug.22,2025

chain-ratchet-pullers-and-hoist-solutions

NewsAug.22,2025

telescopic-hot-stick-for-electrical-and-high-voltage-use

NewsAug.22,2025

cable-clamp-and-insulated-cable-clamp-systems

NewsAug.22,2025

duct-rodder-conduit-rodder-and-cable-solutions

NewsAug.22,2025