Oct . 27, 2025 13:55 Back to list

Cable Pulling Tools – Durable, Safe & Pro-Grade Kits

Why Cable Pulling Tools still make or break power jobs in 2025

On most sites I visit, the quiet heroes aren’t the flashy winches. It’s the drum handling gear that keeps the pull clean, straight, and safe. Case in point: the Cable Drum Roller Jack from China-based manufacturers—solid steel, sensible bearings, and (surprisingly) considerate ergonomics. Sounds simple, but the payoff is huge when reels spin freely and your tension stays predictable.

Product spotlight: Cable Drum Roller Jack

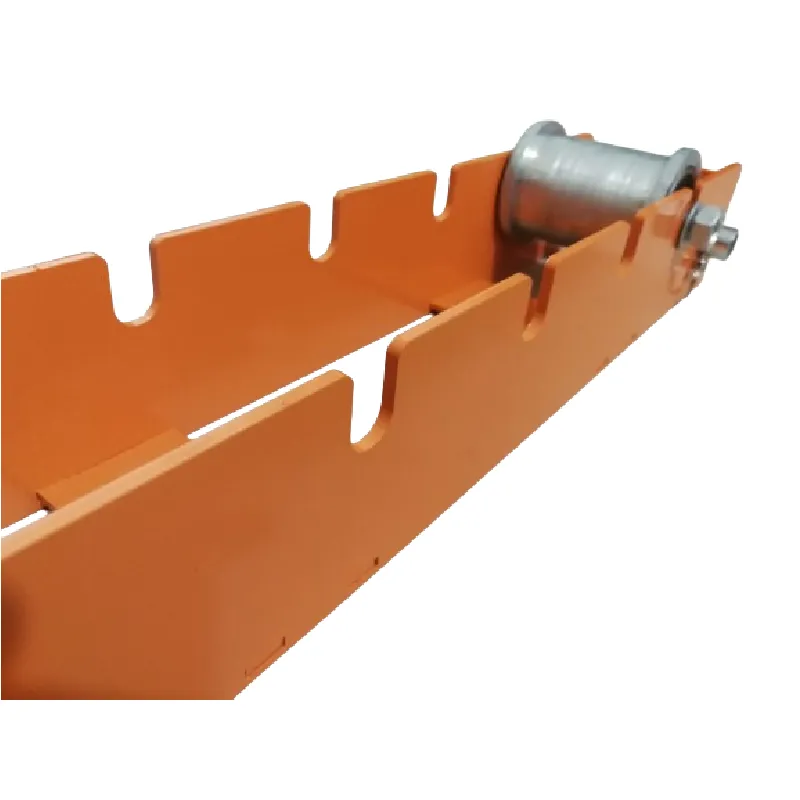

This jack supports and pays off wire from medium-to-large drums. It’s basically a turntable with rollers, a roller axis, and a locking fixture. The rollers ride on internal rolling bearings, so the reel turns with notably low friction—handy when you want steady payout without surges. In field notes, crews said the drum stays “surprisingly calm” even when the puller starts and stops.

Key specifications (typical configuration)

| Load rating | ≈ 3–5 t per pair (real-world use may vary) |

| Compatible drum diameter | 800–3000 mm (adjustable) |

| Roller/bearing set | Sealed rolling bearings, low-friction; radial runout < 0.5 mm |

| Frame material / finish | Q235 steel; powder-coat or hot-dip galvanized |

| Service temperature | -20°C to +55°C (typ.) |

| Origin | China |

Where it shines

- Utility distribution and substation builds (LV/MV/HV reels)

- Data center feeders and campus pulls where tension control matters

- Telecom backbones and fiber micro-duct reels

- Rail, mining, and offshore yards—anywhere steady payout reduces snags

Advantages I’ve seen repeatedly: smoother startup (less initial jerk), lower crew fatigue, and cleaner layer unwinding—which, in turn, reduces jacket scuffing and keeps installation tension under the limits recommended by IEEE and IEC guidance.

Process, materials, and testing

Materials: Q235 steel frame, heat-treated roller axis, sealed bearings (grease-packed). Methods: CNC cutting, MIG welding, dynamic balancing of rollers, and post-paint bake. Typical quality checks include:

- Static proof load: 125% rated capacity (10 min hold)

- Salt-spray corrosion test: 72 h per ASTM B117 (powder-coat) or 240 h for galvanized

- Run tests: 1000 revs under 50% load, temp rise ≤ 20°C

Service life: ≈ 5–8 years in typical utility use; more with proper storage and periodic bearing grease checks. Certifications: factory ISO 9001; CE Declaration and RoHS material statements available on request (varies by batch).

Quick vendor snapshot

| Vendor | Load rating | Finish | Bearings | Lead time | Notes |

|---|---|---|---|---|---|

| Bilopowtel (China) | ≈ 3–5 t | Powder / Galv. | Sealed, low-friction | 2–4 weeks | Good price-to-spec |

| Vendor A (EU) | ≈ 3 t | Galv. | Shielded | 3–5 weeks | Premium pricing |

| Vendor B (US) | ≈ 4 t | Powder | Sealed | Stock/2 weeks | Strong support |

Customization and integration

- Roller material: steel with polymer sleeve for delicate jackets

- Locking fixture options for sloped pads

- Grounding stud and anti-static strap kits for medium-voltage reels

- Accessory fit: line tension meters and brake bars play nicely

Many customers say the simplest add-on—a soft-start brake—pays for itself by keeping cable within max sidewall bearing pressure. That echoes what standards recommend anyway.

Mini case study (utility, APAC)

A 110 kV substation upgrade pulled 3×630 mm² cables over 240 m with two 90° bends. Using this jack set, the crew reported a 12–15% reduction in peak tension vs. their older stands (site logger, ambient 22°C). The foreman told me, “It just feeds cleaner—less babysitting.” That’s exactly what Cable Pulling Tools should do: stay out of the way and let the job flow.

Safety and standards, briefly

Align usage with IEEE guidance for pulling tensions and IEC wiring selection rules; verify proof-load marks, and keep drums chocked. Real-world site conditions vary, so—honestly—don’t skip a pre-pull test. That’s standard craft, but worth repeating for Cable Pulling Tools.

References

- IEEE Std 1185-2020, Guide for Installation of Cables in Generating Stations

- NECA/NEMA 120-2017, Standard for Installing Armored Cable

- IEC 60364-5-52: Selection and erection of electrical equipment—Wiring systems

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus

- ISO 9001:2015 Quality management systems—Requirements

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025