Oct . 16, 2025 09:15 Back to list

Hot Stick - Insulated Fiberglass, ANSI/IEC Rated Telescopic

High Voltage Telescoping Triangle hot stick — field notes from the line

If you’re comparing hot stick options for distribution and transmission work, here’s the short version: the triangle telescoping profile is still the smart choice for control, speed, and ergonomics. I’ve watched crews switch over, and—surprisingly—the most common feedback isn’t “lighter,” it’s “less twisty.” That matters when you’re opening a stubborn disconnect at dawn with a storm front rolling in.

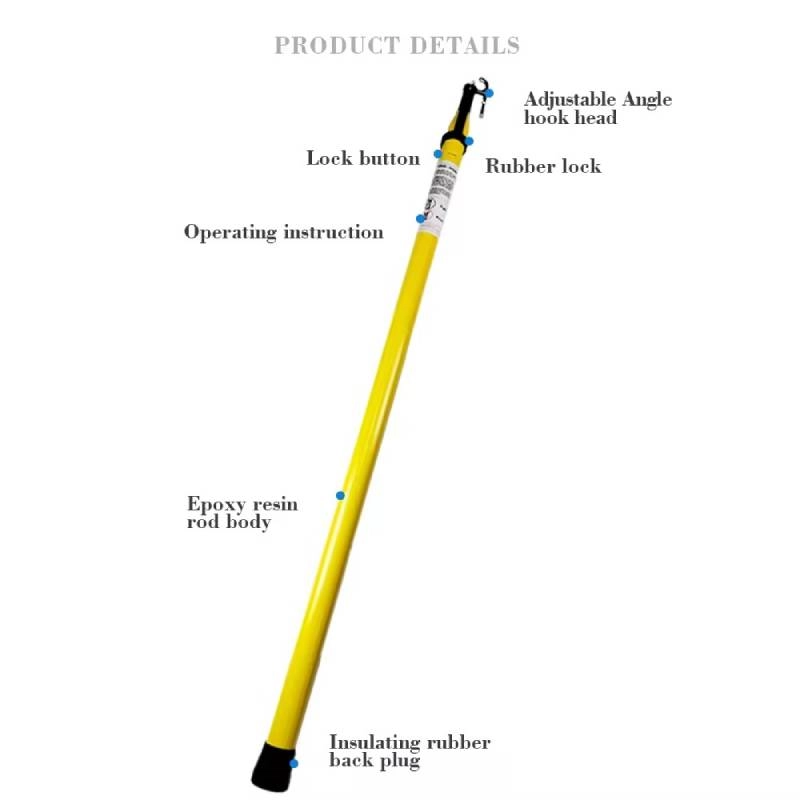

What this tool is, in plain words

Bilopowtel’s High Voltage Telescoping Triangle hot stick is pultruded fiberglass reinforced with epoxy resin, made in China, designed for energized work up to utility-class voltages. With a universal head, you can mount detectors, sockets, fuse pullers, tie-wire tools—you know the drill. The surface is UV-stable with a hydrophobic gloss, so wet-line performance stays predictable.

Industry trends (quick snapshot)

- Triangle anti-rotation tubes are now the default for precision switching.

- More utilities require documented dielectric tests per ASTM/IEC each inspection cycle.

- Growth in wind/solar interconnects is pushing demand for compact, long-reach hot stick kits.

Key specifications (typical)

| Material | Fiberglass (FRP) + epoxy resin, UV-stable varnish |

| Profile | Telescoping triangle, anti-rotation |

| Length (collapsed / extended) | ≈ 1.6 m / 6.4 m (options available) |

| Sections | 4–7 sections (customizable) |

| Dielectric withstand | ≥ 100 kV/ft dry; ≥ 75 kV/ft wet (typ., ASTM F711 test method) |

| Leakage current | |

| Head | Universal spline (fits common utility attachments) |

| Operating temp | -40 °C to +55 °C |

| Origin | China; ISO 9001 factory |

| Standards | ASTM F711, IEC 61235; use per IEEE 516, OSHA 1910.269 |

How it’s made and tested (process flow)

- Materials: E-glass fiber + tough epoxy resin system.

- Method: Pultrusion of triangular tubes; precision machining of joints; universal head fitting.

- Finish: UV-resistant clear coat; hydrophobic polish for wet-line behavior.

- Testing: Dimensional check; dielectric per ASTM F711/IEC 61235; bending/torque; surface contamination index (as needed).

- Traceability: Batch ID, date of test, inspector stamp.

- Service life: ≈ 10–15 years with cleaning, wax, and annual dielectric tests [2][3].

Applications and feedback

Distribution switching, fuse replacement, reclosers, capacitor banks, tie wires, insulating sleeve placement—plus substation tasks where long reach is sanity-saving. Many customers say the triangle hot stick reduces hand fatigue and “wandering” torque. One foreman told me it cut their switching time on a coastal feeder by about 15%—not lab grade data, but it tracks with what I’ve seen.

Vendor comparison (indicative)

| Feature | Bilopowtel | Hastings | Hubbell Chance |

|---|---|---|---|

| Triangle anti-rotation | Yes | Yes | Yes |

| Dielectric spec (dry) | ≥ 100 kV/ft | ≈ 100 kV/ft | ≈ 100 kV/ft |

| Lead time | ≈ 2–4 weeks | ≈ 3–6 weeks | ≈ 3–6 weeks |

| Price band | $–$$ | $$–$$$ | $$–$$$ |

| Customization | Length/sections, color, logos | Length/attachments | Length/attachments |

Customization & attachments

- Lengths from compact patrol sticks to substation long-reach.

- Universal head for voltage indicators, socket heads, fuse pullers, tie tools.

- Logo and color options for fleet ID; serialized labels for audits.

A quick case study

A Southeast utility deployed 40 triangle hot stick sets for feeder switching and cutouts. After retraining per IEEE 516 procedures, they reported fewer re-position attempts on disconnect blades and improved wet-weather control. The maintenance shop logged higher pass rates at annual dielectric checks—likely due to more consistent cleaning/wax routines baked into the new SOP.

Safety, compliance, and care

- Use per OSHA 1910.269 and utility work methods (live-line, barehand, or URD).

- Clean and wax regularly; inspect for nicks, gloss loss, contamination.

- Document dielectric/bend tests per ASTM F711 and IEC 61235; keep certificates on file.

Authoritative citations

- ASTM F711 – Standard Specification for Fiberglass-Reinforced Plastic (FRP) Rod and Tube Used in Live-Line Tools. https://www.astm.org/f0711

- IEC 61235 – Live working – Insulating rods and foam-filled tubes. https://webstore.iec.ch

- IEEE 516 – Guide for Maintenance Methods on Energized Power Lines. https://standards.ieee.org

- OSHA 1910.269 – Electric Power Generation, Transmission, and Distribution. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.269

- EPRI Live Working Reference Guide (overview). https://www.epri.com

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025