-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Nov . 03, 2024 21:24 Back to list

1 2 inch ground rod

Understanding 1% 2% Inch Ground Rods Essential Components for Electrical Safety

In the realm of electrical installations, grounding systems play a critical role in ensuring safety and reliability. A key component of these systems is the ground rod, which provides a direct electrical connection to the earth. Among various types of ground rods, the 1% 2% inch ground rod stands out for its durability and effectiveness in dissipating electrical faults.

What is a Ground Rod?

A ground rod, often made of materials such as copper or galvanized steel, is a long, thin metal rod that is driven into the ground to establish a low-resistance path to the earth. This is crucial in protecting electrical systems from surges, lightning strikes, and equipment failures. The dimensions and material of the ground rod can significantly affect its performance, with the 1% 2% inch measurements being particularly popular due to their balance between ease of installation and performance.

Importance of 1% 2% Inch Ground Rods

The designation of 1% 2% inch typically refers to the thickness and diameter of the rod—values that contribute to the rod’s strength and conductivity. These rods are sufficiently robust to withstand harsh environmental conditions while maintaining a strong electrical connection to the ground. A robust ground rod minimizes the impedance, allowing for efficient dissipation of electrical faults.

One of the primary advantages of using a 1% 2% inch ground rod is its compatibility with various grounding systems. Electricians and engineers favor these rods for residential, commercial, and industrial applications because they can be easily integrated into existing frameworks. Whether it’s for preventing electrical shock, protecting equipment, or ensuring compliance with local electrical codes, these ground rods are a reliable choice.

1 2 inch ground rod

Installation Considerations

Proper installation is vital for maximizing the effectiveness of a ground rod. When installing a 1% 2% inch ground rod, it is essential to

1. Select the Right Location The chosen site should be free of obstructions like underground utilities, and away from sources of contamination that may affect conductivity. 2. Drive the Rod Deep Enough Typically, a ground rod should be driven at least 8 feet deep into the ground, but local regulations may dictate specific requirements. Deeper installation improves grounding efficiency.

3. Ensure Proper Connections All connections must be tightly secured to ensure a low-resistance path. Corrosion-resistant connectors are recommended for longevity.

4. Test the Grounding System After installation, testing the resistance of the grounding system is crucial. A well-grounded installation should ideally have less than 25 ohms of resistance.

Conclusion

The 1% 2% inch ground rod serves as an indispensable component of electrical grounding systems. By providing a reliable connection to the earth and ensuring safety against electrical faults, these rods play a crucial role in the overall health of electrical installations. By understanding their importance and adhering to proper installation practices, professionals can significantly enhance electrical safety and performance, safeguarding both people and equipment from potential dangers.

Latest news

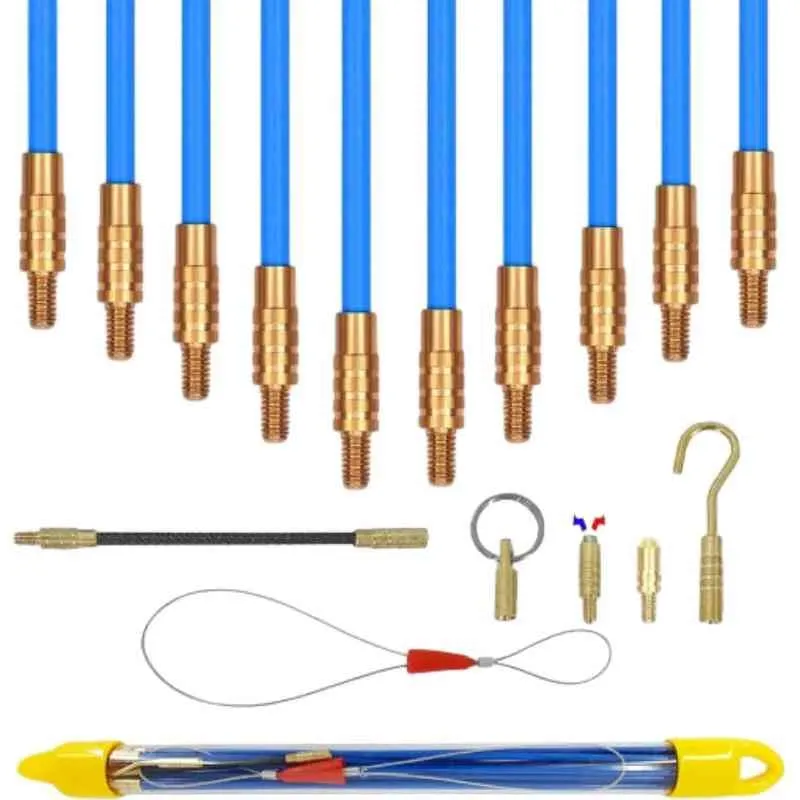

Your Best Choice for Duct Rodder and Fish Tape Wire Puller Tools

NewsAug.13,2025

Unlocking Efficiency and Precision with Premium Cable Tools and Equipment

NewsAug.13,2025

Smart Solutions with Precision: Cable Pulling Tools That Deliver

NewsAug.13,2025

Reliable Protection with Advanced Hot Stick Technology

NewsAug.13,2025

Reliable Cable Installation Tools at Your Fingertips

NewsAug.13,2025

Optimized Cable Laying with Heavy-Duty Solutions for Modern Projects

NewsAug.13,2025