-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

дец . 26, 2024 21:46 Back to list

heavy duty hydraulic crimping tool

Heavy Duty Hydraulic Crimping Tools Essential for Industrial Applications

In the world of industrial manufacturing and electrical work, the importance of reliable tools cannot be overstated. Among the essential equipment that professionals rely on, heavy-duty hydraulic crimping tools stand out as indispensable devices for a variety of applications. These tools facilitate the joining of cables and connectors in a seamless and efficient manner, ensuring the integrity and longevity of electrical connections. This article explores the features, benefits, applications, and maintenance of heavy-duty hydraulic crimping tools.

Understanding Hydraulic Crimping Tools

Hydraulic crimping tools utilize hydraulic pressure to change the shape of a connector, allowing it to grip wires firmly and securely. The mechanism involves a hydraulic cylinder that generates immense force, enabling the tool to apply consistent pressure and achieve a high-quality crimp. This process is crucial for creating reliable electrical connections, particularly in high-stress environments where vibration and movement can lead to failure.

Features That Set Them Apart

1. High Capacity Heavy-duty hydraulic crimping tools are designed to handle larger cables and connectors, typically ranging from 6 mm² to 400 mm². This capacity makes them suitable for industrial settings, where thick cables are often the norm.

2. Versatile Crimping Dies Most hydraulic crimping tools come with interchangeable crimping dies, allowing users to work with various connector sizes and types. This versatility ensures that a single tool can cater to multiple needs, enhancing productivity.

3. Durable Construction These tools are often made from high-strength materials such as steel, ensuring durability and resistance to wear and tear. Many models also feature ergonomic handles designed for comfort and to reduce operator fatigue during extended use.

4. Precise Crimping The hydraulic mechanism allows for consistent and precise crimping results. This precision is vital in ensuring that electrical connections are secure and able to withstand operational stresses.

Benefits of Using Hydraulic Crimping Tools

1. Efficiency One of the most significant advantages of hydraulic crimping tools is their ability to complete crimping tasks quickly. The hydraulic system reduces the amount of manual force required, allowing professionals to finish projects faster and move on to the next task.

2. Quality Connections Crimping done with hydraulic tools is often more reliable than manual crimping, as it ensures an even distribution of pressure across the connector. This quality is critical in preventing future failures, which can lead to costly downtime in industrial applications.

heavy duty hydraulic crimping tool

3. Safety Properly crimped connections reduce the risk of electrical faults, which can pose safety hazards in the workplace. By investing in heavy-duty hydraulic crimping tools, companies can enhance workplace safety and reduce liability concerns.

4. Cost-Effective While the initial investment in a hydraulic crimping tool may be higher than traditional manual crimpers, the long-term savings associated with reduced downtime, fewer failures, and increased productivity make them a wise investment.

Applications Across Industries

Heavy-duty hydraulic crimping tools find applications in various sectors, including

- Electrical Utilities Used to join thick cables in power distribution and grid connections, ensuring that electrical flow remains uninterrupted. - Construction Employed in the installation of heavy machinery, where durable electrical connections are essential for operational safety and efficiency. - Automotive Utilized in auto manufacturing for wiring harnesses and connections in electric and hybrid vehicles.

- Telecommunications Critical for crimping cables in network infrastructure, ensuring that data transmission remains stable and reliable.

Maintenance Tips for Longevity

To ensure the longevity and performance of hydraulic crimping tools, regular maintenance is necessary

- Clean After Use Remove any debris or metal shavings after each use to prevent wear and tear.

- Regular Inspections Check the hydraulic fluid levels and inspect the tool for any signs of damage or wear.

- Proper Storage Store the tool in a dry and stable environment to avoid exposure to elements that could cause rust or degradation.

In conclusion, heavy-duty hydraulic crimping tools are vital assets in various industries, providing efficiency, safety, and reliability in cable and connector applications. By understanding their functionality and maintaining them properly, professionals can ensure that they achieve the best performance from their tools, leading to excellent results in their electrical projects. Whether you are a seasoned professional or someone new to the industry, investing in a quality hydraulic crimping tool is a step towards achieving better productivity and quality in your work.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

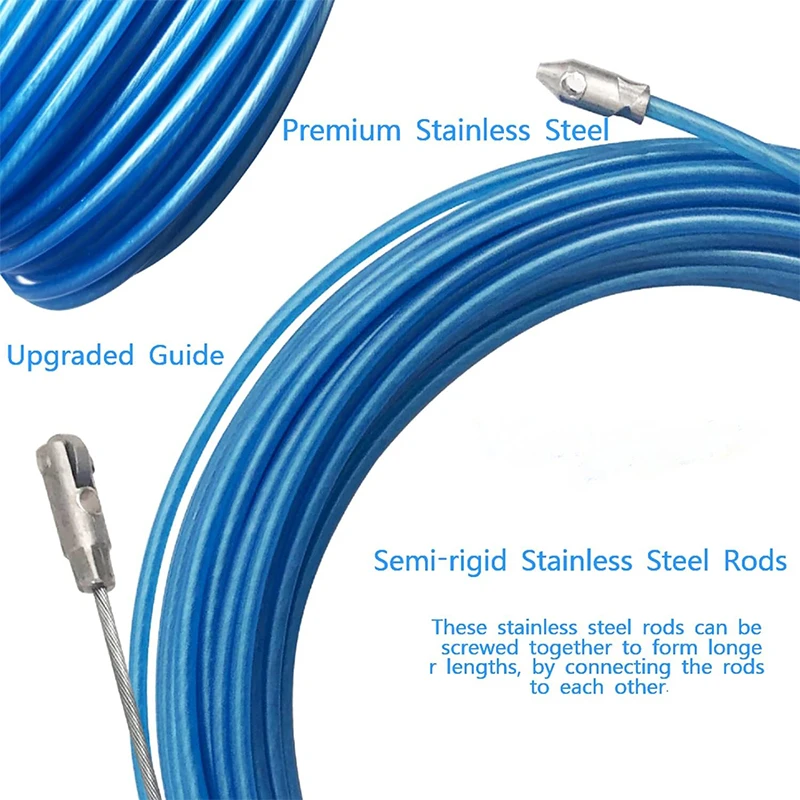

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025