-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Nën . 15, 2024 03:22 Back to list

i beam winch

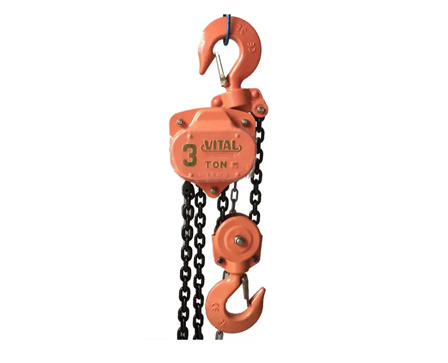

Understanding the I-Beam Winch An Essential Tool in Material Handling

When it comes to lifting heavy loads in industrial settings, the I-beam winch stands out as one of the most effective and reliable tools available. Commonly utilized in warehouses, construction sites, and factories, the I-beam winch is designed to provide efficient lifting solutions where conventional hoisting methods may fall short. This article will delve into the structure, versatility, and applications of the I-beam winch, elucidating why it is an essential component in material handling systems.

The Structure of an I-Beam Winch

The I-beam winch gets its name from its distinctive I-shaped beam, which serves as both the guide and support for the winch mechanism. The beam is typically made of high-strength steel, granting it the durability needed to handle heavy loads. The design of the I-beam allows for optimal load distribution, reducing the risk of deformation or failure under extreme weights.

At the heart of the winch mechanism is the drum where the lifting cable or chain is wound. When the winch is engaged, the drum rotates, allowing the cable to either unfurl or wind up, facilitating the lifting and lowering of loads. This system can be operated manually or powered by electric or pneumatic motors, depending on the specific application and the required lifting capacity.

Versatility in Applications

One of the key advantages of the I-beam winch is its versatility. These winches can be adapted for a variety of applications, making them valuable in numerous industries. In manufacturing environments, for instance, the I-beam winch is often employed to lift components during assembly or to transfer products along production lines. It can easily be integrated into overhead rail systems, allowing for seamless movement throughout the workspace.

i beam winch

In the construction industry, I-beam winches are indispensable for hoisting materials to elevated work areas. They can handle everything from steel beams and concrete blocks to tools and equipment, streamlining construction processes and improving safety. Additionally, their capability to be mounted on existing I-beams or girders makes them a perfect choice for temporary setups, thus enhancing their utility.

This winch type is also commonly found in maintenance and repair operations, where heavy equipment and machinery need to be lifted or repositioned. In these scenarios, the I-beam winch enhances operational efficiency by reducing manual lifting efforts and minimizing the risk of injury to workers.

Safety Features and Considerations

Safety is paramount in any lifting operation, and the I-beam winch is designed with numerous safety features to protect both the load and the operator. Many winches are equipped with overload protection systems that automatically disengage the mechanism when the load exceeds a predetermined limit. Other safety features may include brake systems that ensure the load remains stationary when not in motion.

However, proper training and adherence to safety protocols are crucial when operating an I-beam winch. Operators should be well-versed in weight capacities, load balancing, and rigging techniques to prevent accidents. Furthermore, regular maintenance checks are necessary to ensure the winch functions correctly and remains in optimal condition.

Conclusion

In conclusion, the I-beam winch is a powerful tool that enhances the efficiency and safety of material handling in various industrial applications. Its robust construction, versatile design, and array of safety features make it an indispensable asset for lifting heavy loads. As industries continue to evolve and adopt advanced technologies, the I-beam winch will undoubtedly remain a key component in shaping the landscape of material handling equipment. Whether on construction sites, in manufacturing plants, or in repair shops, the value of the I-beam winch cannot be overstated, making it a go-to solution for lifting challenges across the board.

Latest news

The Unique Design of Cable Socks

NewsJun.04,2025

Swivel Connectors in Industrial Automation

NewsJun.04,2025

Safety Features of Link Sticks

NewsJun.04,2025

How to choose the best cable pulling winch for sale

NewsJun.04,2025

Fish tape safety precautions

NewsJun.04,2025

Essential Maintenance Tips for Cable Pulling Tools

NewsJun.04,2025