Sep . 19, 2025 10:30 Back to list

Professional Cable Pulling Tools & Equipment for Efficient Installs

Advancing Infrastructure with Precision Cable Pulling Solutions

In the intricate landscape of modern infrastructure development, the efficient and secure installation of cables is paramount. From high-voltage power lines to complex telecommunication networks and critical industrial cabling, the tools employed directly impact project timelines, safety, and long-term operational integrity. Our focus today is on critical cable pulling tools, essential components that facilitate the precise routing and installation of cables across diverse and challenging environments. These specialized devices, encompassing everything from sophisticated winches to durable guide rollers, are engineered to minimize friction, prevent cable damage, and enhance worker safety, thereby optimizing the entire installation process for B2B stakeholders.

The escalating demand for robust and reliable cabling infrastructure in sectors such as renewable energy, data centers, and urban development underscores the continuous evolution and importance of high-performance cable pulling tools. This article delves into the technical intricacies, application advantages, and strategic considerations for selecting and deploying these indispensable engineering assets.

Industry Trends in Cable Pulling Technology

The industry for cable pulling tools is undergoing significant transformation, driven by demands for increased efficiency, enhanced safety, and greater sustainability. Key trends shaping this sector include:

- Automation and Digitalization: The integration of smart controls, IoT sensors, and predictive maintenance capabilities into cable pulling equipment is becoming standard. This allows for real-time monitoring of pulling forces, speeds, and cable tension, preventing overstress and damage. For instance, advanced cable pulling winch systems now feature programmable logic controllers (PLCs) and remote operation functionalities, significantly improving operational precision and safety on site.

- Ergonomic Design and User Safety: A strong emphasis is placed on designing tools that reduce physical strain on operators and minimize accident risks. Lightweight, modular designs, and intuitive interfaces are becoming prevalent across all types of cable pulling tools, including sophisticated cable tray rollers and manual pulling devices.

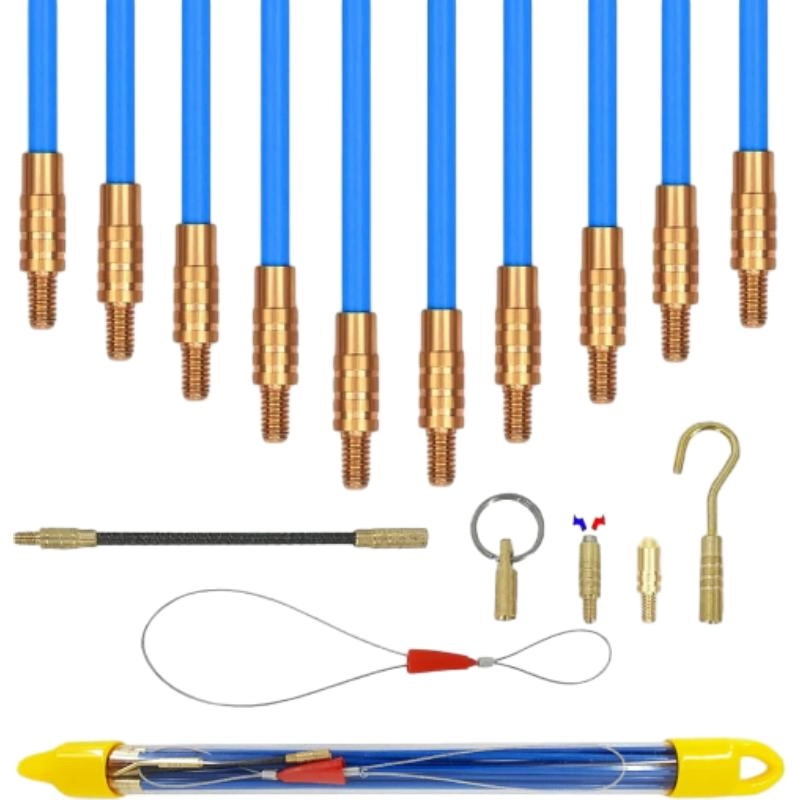

- Material Innovation: The use of advanced composites and high-strength alloys is leading to lighter yet more robust tools. For example, fiberglass or carbon fiber push-pull rods offer superior rigidity and reduced weight compared to traditional metallic options, improving maneuverability and reducing fatigue during long installations.

- Sustainability and Energy Efficiency: Manufacturers are developing tools with lower power consumption and longer service lives. Electric-powered winches, for example, are gaining favor over hydraulic systems due to their reduced environmental footprint and quieter operation.

- Versatility and Modularity: Tools designed for multi-purpose applications and easy configuration reduce the need for specialized equipment for every task, streamlining inventory and operational logistics. This includes adaptable pulling grips and cable pulling sock designs that accommodate a wider range of cable diameters.

The Manufacturing Process of Cable Pulling Tools

The production of high-quality cable pulling tools involves a meticulous multi-stage process, ensuring durability, precision, and adherence to stringent performance standards. A typical manufacturing flow for components like Push Pull Rods or high-strength pulling grips involves:

- Material Selection:

- High-Strength Steel Alloys: For components requiring extreme tensile strength and wear resistance (e.g., winch drums, grip jaws), specialized alloys like Cr-Mo (Chromium-Molybdenum) or heat-treated structural steels are chosen.

- Advanced Composites: For lighter-weight applications such as push-pull rods, materials like fiberglass reinforced polymer (FRP) or carbon fiber composites are utilized, offering excellent strength-to-weight ratios and electrical insulation properties.

- Corrosion-Resistant Materials: Stainless steel (e.g., 304, 316) is often used for outdoor or marine applications where exposure to corrosive elements is anticipated, ensuring extended service life.

- Primary Forming (Casting/Forging):

- Casting: Complex shapes or large components might undergo sand or investment casting, followed by stress relieving and initial machining.

- Forging: For critical components requiring superior strength and grain structure refinement, hot or cold forging processes are employed. This enhances mechanical properties and eliminates internal defects.

- Precision Machining (CNC Machining):

- Computer Numerical Control (CNC) machining centers are used to achieve tight tolerances and intricate geometries. This is critical for parts like gears, shafts, rollers, and connecting mechanisms, ensuring smooth operation and precise fit.

- Heat Treatment:

- Carburizing, nitriding, quenching, and tempering processes are applied to specific steel components to enhance surface hardness, wear resistance, and overall mechanical strength, extending the service life of cable pulling equipment.

- Surface Finishing and Coating:

- Protective coatings like galvanization, powder coating, or specialized anti-corrosion paints are applied to resist environmental degradation, UV exposure, and chemical attack, especially for tools used in petrochemical or water supply & drainage industries.

- Assembly and Integration:

- Components are carefully assembled, often involving sophisticated bearing systems, hydraulic or electric motor integration, and electronic controls for advanced winches.

- Quality Control & Testing Standards:

- Each batch and often individual units undergo rigorous testing, including tensile strength tests, fatigue tests, operational load tests, and material composition analysis. Adherence to international standards like ISO 9001 for quality management, ANSI/ASME standards for mechanical components, and specific industry norms (e.g., for electrical safety or ATEX for hazardous environments) is paramount.

- Non-destructive testing (NDT) methods such as ultrasonic testing and magnetic particle inspection ensure the absence of internal flaws.

This stringent process ensures an extended service life, typically ranging from 5 to 15 years or more depending on maintenance and usage intensity. Target industries include petrochemical, metallurgy, energy, telecommunications, and water supply & drainage. The advantages in these scenarios include energy saving through optimized friction reduction, exceptional corrosion resistance in harsh environments, and reduced downtime due to tool failure.

Technical Specifications and Parameters of Representative Cable Pulling Rods

Understanding the detailed technical parameters of cable pulling tools is crucial for project planning and execution. Below is a specification table for typical Push Pull Rods, which are fundamental for conduit and duct installation, highlighting key performance indicators:

These specifications highlight the engineered precision that goes into modern cable pulling tools, providing contractors and engineers with reliable solutions for challenging installation projects.

Application Scenarios Across Industries

The versatility of modern cable pulling tools makes them indispensable across a wide array of industrial and commercial applications:

- Telecommunications Infrastructure: Essential for installing fiber optic and copper cables in ducts and conduits, both underground and within buildings. Advanced tools ensure minimal signal loss by preventing cable stress and micro-bends.

- Power Distribution: Used for pulling medium and high-voltage power cables through underground conduits, overhead lines, and within substations. High-capacity cable pulling winch systems are critical here.

- Oil & Gas / Petrochemical: In hazardous and corrosive environments, specialized non-sparking and corrosion-resistant cable pulling tools are vital for laying control, instrumentation, and power cables.

- Water Treatment & Municipal Utilities: For installing electrical and data cables in often damp or confined spaces, ensuring reliable power to pumps, monitoring systems, and control units.

- Construction and Building Services: Facilitating the installation of electrical wiring, data cables, and security systems in commercial, industrial, and residential buildings, often navigating complex architectural layouts.

- Renewable Energy (Wind/Solar Farms): Deploying large-diameter power cables across vast distances and challenging terrains, connecting turbines or solar arrays to the grid.

Technical Advantages of Advanced Cable Pulling Tools

Investing in high-quality cable pulling equipment offers significant technical and operational advantages:

- Reduced Cable Damage: Precision-engineered rollers, such as robust cable tray rollers and specialized cable pulling sock designs, distribute pulling forces evenly and minimize friction, preventing costly damage to insulation, conductors, or fiber optics.

- Enhanced Safety: Automated systems, remote controls, and robust mechanical designs significantly reduce manual handling risks, protecting personnel from strain injuries and accidents. Tools designed to meet OSHA and other safety standards are paramount.

- Increased Efficiency: Faster setup times, smoother pulling operations, and reduced need for manual intervention translate directly into shortened project durations and labor cost savings. Efficient pulling can reduce installation time by up to 30% compared to traditional methods.

- Extended Tool Lifespan: High-grade materials and advanced manufacturing processes ensure longevity, even under heavy-duty usage and harsh environmental conditions. This translates to lower total cost of ownership (TCO) over the asset's lifecycle.

- Versatility and Adaptability: Modular and customizable tools can be adapted to various cable types, sizes, and installation environments, maximizing utility and return on investment.

Vendor Comparison: Key Differentiators in Cable Pulling Solutions

When selecting a supplier for cable pulling tools, B2B decision-makers must evaluate several critical factors beyond initial purchase price. A strategic vendor comparison table is essential:

Choosing a specialist vendor like Bilopowtel ensures access to advanced technologies, superior quality, and a partnership approach that delivers optimal performance and long-term value for complex projects involving cable pulling equipment.

Customized Solutions for Unique Project Demands

While standard cable pulling tools address a broad spectrum of requirements, many large-scale or niche projects necessitate tailored solutions. Recognizing this, leading manufacturers offer extensive customization capabilities:

- Bespoke Rod Lengths and Diameters: For conduits with unusual dimensions or exceptionally long runs, rods can be manufactured to specific lengths and diameters, ensuring optimal flexibility and pushing force.

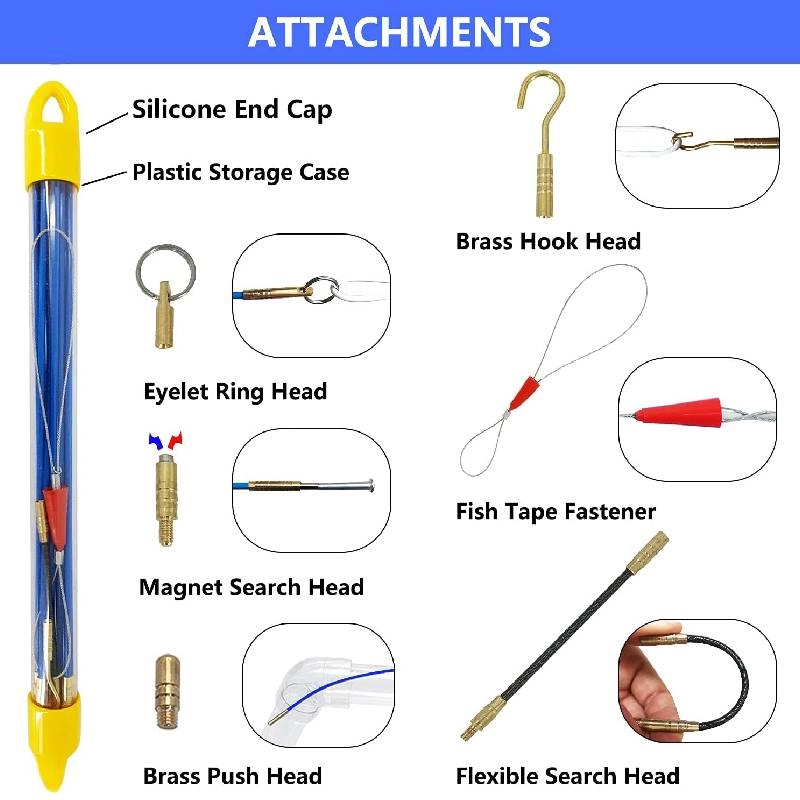

- Specialized Attachments: Custom guide heads, pulling eyes, or roller configurations can be designed to navigate highly complex duct routes or handle non-standard cable profiles.

- Material Adaptation: For extreme environments, such as those with high temperatures, aggressive chemicals, or specific electrical insulation requirements, alternative materials beyond standard FRP or steel can be engineered.

- Integrated Sensor Technology: Custom solutions can incorporate real-time tension sensors, inclinometers, or GPS tracking directly into cable pulling equipment for advanced data logging and process optimization.

This bespoke approach ensures that even the most challenging cable installation projects can be executed safely, efficiently, and with minimal risk of complications, demonstrating the manufacturer's expertise and commitment to solving complex engineering challenges.

Application Case Studies

Case Study 1: Urban Fiber Optic Network Expansion

Challenge: A major metropolitan telecommunications provider faced the challenge of deploying 50km of new fiber optic cable through existing, congested underground conduits in a dense urban environment. The conduits featured multiple bends and varied diameters, posing a high risk of cable damage and installation delays.

Solution: The project utilized a combination of high-flexibility FRP Push Pull Rods (11mm diameter, 1.5m sections) and a digitally controlled cable pulling winch equipped with tension monitoring. Specialized cable tray rollers were strategically placed at manholes to guide the cable smoothly.

Result: The robust yet flexible cable pulling tools facilitated successful cable deployment across 98% of the planned routes, minimizing manual effort and significantly reducing installation time by an estimated 25%. Cable integrity was maintained throughout, as verified by post-installation optical time-domain reflectometer (OTDR) tests, leading to immediate network activation.

Case Study 2: Offshore Wind Farm Power Cable Installation

Challenge: Installing subsea export cables from an offshore wind turbine to an onshore substation required pulling large diameter, heavy power cables through pre-laid protective ducts over several kilometers. The marine environment demanded highly durable and corrosion-resistant cable pulling equipment.

Solution: A high-tonnage, marine-grade cable pulling winch with synchronized pulling capabilities was employed. Custom-fabricated stainless steel cable pulling sock grips, designed for heavy loads and marine conditions, were used. Real-time tension monitoring ensured the cable's structural integrity during the critical pull-in phases.

Result: Despite challenging weather conditions, the cable was successfully pulled through the protective ducts with precise tension control, avoiding any damage to the expensive subsea asset. The project was completed ahead of schedule, showcasing the reliability and robustness of the specialized cable pulling tools in extreme environments.

Ensuring Trust and Authority: Our Commitment

Building lasting partnerships in the B2B sector requires unwavering trust and demonstrable authority. We uphold these principles through:

- Certifications and Compliance: Our manufacturing facilities are ISO 9001:2015 certified, guaranteeing robust quality management systems. Our products comply with relevant international safety and performance standards, including CE marking where applicable.

- Years of Service & Client Trust: With over a decade of dedicated service in the industry, we have cultivated a strong reputation for reliability and innovation, partnering with leading engineering firms and utility providers globally.

- Extensive Testing & Data Validation: All cable pulling tools undergo rigorous in-house and third-party testing. Performance data, including tensile strength, durability, and material integrity, is available upon request to validate specifications.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for customized cable pulling rods?

A: Standard products are typically shipped within 3-5 business days. For customized cable pulling tools, lead times vary based on complexity and material availability, generally ranging from 2 to 4 weeks after design confirmation. We provide precise estimates during the quotation process.

Q: What warranty is offered on your cable pulling equipment?

A: We offer a standard 12-month warranty on all manufacturing defects from the date of purchase. Extended warranty options are available for major systems like cable pulling winch units, ensuring peace of mind for our clients.

Q: How do you handle after-sales support and spare parts?

A: Our dedicated customer support team provides comprehensive after-sales assistance, including technical advice, troubleshooting, and expedited spare parts delivery. We maintain an extensive inventory of common components to minimize downtime for our partners.

Lead Time & Fulfillment

Our robust supply chain and efficient manufacturing processes enable us to offer competitive lead times. For standard components, orders are typically fulfilled within 2-7 business days, with expedited shipping options available. Complex or large-volume orders are managed with dedicated project managers to ensure timely delivery and seamless logistical coordination, directly supporting critical project schedules.

Warranty Commitments

All products are backed by a comprehensive warranty, covering manufacturing defects and ensuring materials and workmanship meet the highest industry standards. Specific warranty periods are detailed in product documentation, typically ranging from 1 to 5 years depending on the complexity and application of the cable pulling equipment.

Customer Support Information

Our global support network provides expert technical assistance, product training, and responsive service. Clients can reach our support team via dedicated hotlines, email, or through our online portal for prompt resolution of any inquiries or issues, ensuring operational continuity for your projects.

Conclusion

The evolving demands of modern infrastructure require increasingly sophisticated and reliable cable pulling tools. By embracing innovation, precision manufacturing, and rigorous quality control, manufacturers are delivering solutions that not only meet but exceed performance expectations. For B2B stakeholders, choosing the right tools and partners is a strategic decision that impacts project efficiency, safety, and overall profitability in an increasingly competitive global market.

References

- International Organization for Standardization (ISO). ISO 9001:2015 Quality management systems – Requirements.

- National Electrical Code (NEC). NFPA 70: Standard for Electrical Safety in the Workplace.

- Occupational Safety and Health Administration (OSHA). General Industry and Construction Standards.

- IEEE Std 80-2013, IEEE Guide for Safety in AC Substation Grounding.

- CENELEC. EN 50522:2010 Earthing of power installations exceeding 1 kV a.c.

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025