-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Oct . 02, 2024 23:25 Back to list

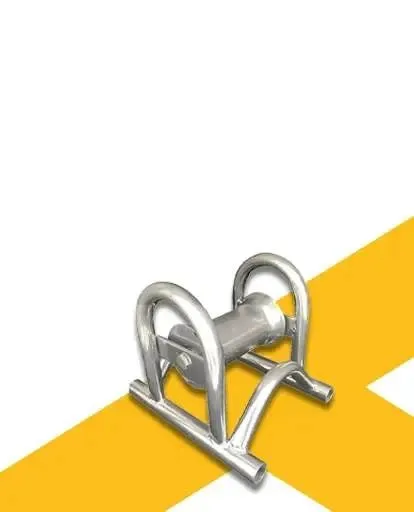

Durable Stainless Steel Wire Ties for Versatile Applications and Secure Binding Solutions

The Versatility of Stainless Steel Wire Ties

Stainless steel wire ties are an invaluable tool in a variety of industries and applications, thanks to their robust properties and versatile functionality. Unlike traditional wire ties made from other materials, stainless steel offers superior strength, corrosion resistance, and longevity, making it an ideal choice for both indoor and outdoor use.

The Versatility of Stainless Steel Wire Ties

In the realm of construction and engineering, stainless steel wire ties are essential for bundling and securing various materials. They provide reliable fastening solutions for cables, pipes, and other structural elements. Their high tensile strength ensures that they can withstand significant tension and pressure without snapping, making them a preferred choice for heavy-duty applications.

stainless wire ties

Moreover, stainless steel wire ties are easy to manipulate. They can be bent, twisted, and shaped to accommodate numerous applications. This flexibility allows users to create custom solutions for their specific needs, whether it’s securing equipment on a job site or bundling electrical wires in an industrial setting. Various gauges and configurations are available, allowing users to select the appropriate type of wire tie based on the particular requirements of their project.

In addition to their practical benefits, stainless steel wire ties can also contribute to sustainability efforts. By choosing durable materials that last longer and require less frequent replacement, businesses can reduce waste in their operations. Furthermore, stainless steel is 100% recyclable, making it an environmentally friendly option for various applications.

In conclusion, stainless steel wire ties are an essential tool that combines strength, longevity, and versatility. Their ability to perform in challenging environments and their ease of use make them a go-to choice across multiple sectors. As industries continue to seek reliable and durable solutions, the demand for stainless steel wire ties is likely to increase, solidifying their place as a key component in modern manufacturing and engineering practices.

Latest news

Upgrade Your Cable Installation with the Right Rodder Tools

NewsMay.28,2025

Maximize Efficiency with the Right Cable Laying Tools

NewsMay.28,2025

Mastering Cable Installation: Tools That Make the Difference

NewsMay.28,2025

Solutions for Heavy-Duty Cable Handling: Choosing the Right Cable Roller

NewsMay.28,2025

Efficient Cable Installation Starts with the Right Rodder Tools

NewsMay.28,2025

Choosing the Right Cable Pulling Tools for Your Project

NewsMay.28,2025