-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

පෙබ. . 16, 2025 04:51 Back to list

hot stick for electrical work

The evolution of electrical work safety tools has been profound, yet there's one indispensable device that remains at the forefront of the industry the hot stick. For those immersed in electrical work, especially in high-voltage environments, understanding the intricacies and benefits of using this tool is crucial in ensuring both personal safety and work efficiency.

Cutting-edge Technology Integration Some of the latest innovations in hot stick technology include integrated digital readings that provide real-time feedback on line voltage. These enhancements significantly mitigate the potential for human error. Furthermore, the implementation of intuitive modular design allows for quicker attachment swaps, enhancing efficiency and safety on-site. Real-world Application and Scenarios In a recent deployment for storm damage repair, utility workers utilized hot sticks to safely manage downed power lines, an application demonstrating the tool’s necessity in emergency scenarios. Reports noted that the ergonomic design of the new model hot sticks resulted in a notable reduction in fatigue for the workers over extended shifts, thereby enhancing productivity while maintaining safety. Building Trust through Quality Assurance Reputable manufacturers of hot sticks undergo extensive testing phases, often exceeding industry standards, to guarantee the utmost reliability of their products. Certifications from independent testing bodies provide an additional layer of assurance that these tools will perform reliably under duress. This commitment to quality and safety is paramount, as the slightest flaw in design can lead to catastrophic consequences. Conclusion An Indispensable Tool for Electrical Safety The hot stick remains an irreplaceable component of any professional electrical worker’s arsenal. With continued advancements in technology and design, this tool has not only revolutionized safety practices but also enhanced operational efficiency. For those committed to excellence in electrical work, investing in a high-quality hot stick is not just an option—it's an imperative, underscoring a commitment to safety, precision, and professionalism in every task undertaken.

Cutting-edge Technology Integration Some of the latest innovations in hot stick technology include integrated digital readings that provide real-time feedback on line voltage. These enhancements significantly mitigate the potential for human error. Furthermore, the implementation of intuitive modular design allows for quicker attachment swaps, enhancing efficiency and safety on-site. Real-world Application and Scenarios In a recent deployment for storm damage repair, utility workers utilized hot sticks to safely manage downed power lines, an application demonstrating the tool’s necessity in emergency scenarios. Reports noted that the ergonomic design of the new model hot sticks resulted in a notable reduction in fatigue for the workers over extended shifts, thereby enhancing productivity while maintaining safety. Building Trust through Quality Assurance Reputable manufacturers of hot sticks undergo extensive testing phases, often exceeding industry standards, to guarantee the utmost reliability of their products. Certifications from independent testing bodies provide an additional layer of assurance that these tools will perform reliably under duress. This commitment to quality and safety is paramount, as the slightest flaw in design can lead to catastrophic consequences. Conclusion An Indispensable Tool for Electrical Safety The hot stick remains an irreplaceable component of any professional electrical worker’s arsenal. With continued advancements in technology and design, this tool has not only revolutionized safety practices but also enhanced operational efficiency. For those committed to excellence in electrical work, investing in a high-quality hot stick is not just an option—it's an imperative, underscoring a commitment to safety, precision, and professionalism in every task undertaken.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

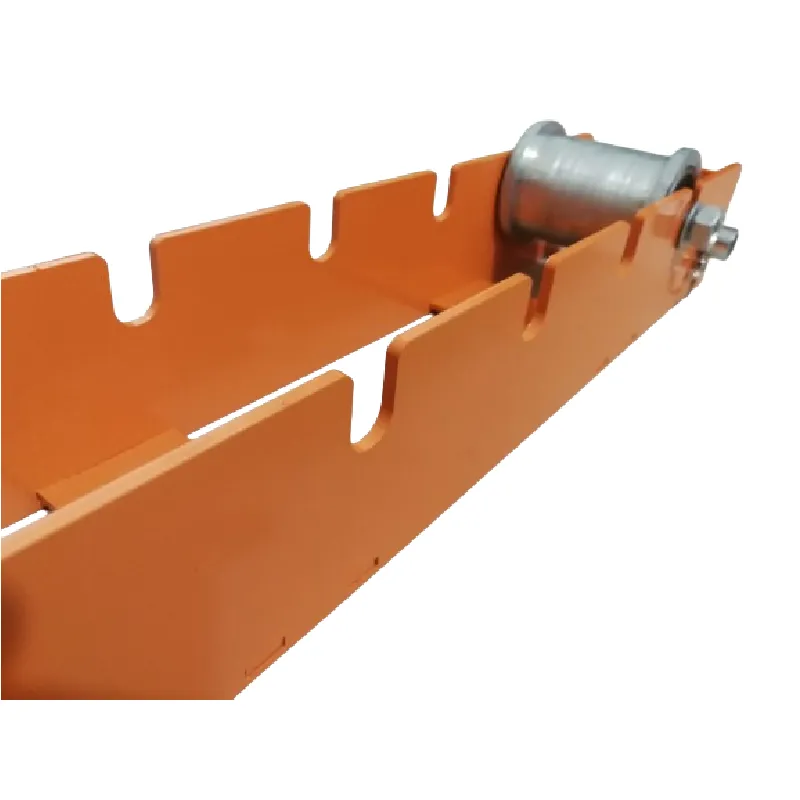

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy