-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

Fev . 19, 2025 10:13 Back to list

Cable Pulling Swivel

The meticulous art of welding an earth wire is an often-overlooked yet essential aspect of ensuring electrical safety and integrity in a myriad of applications. As industries continue to expand and innovate, the importance of securely grounding electrical systems cannot be overstated. This article delves into the intricate process of welding earth wires, offering insights that blend technical expertise with practical experience.

In field applications, the expertise of the welder is paramount. Experienced welders can adapt to varying conditions, whether it be harsh weather, confined spaces, or challenging positions. They know how to manipulate their tools and materials with precision, ensuring that each weld is executed flawlessly. This adaptability is rooted in a deep understanding of both the theoretical and practical aspects of welding, cultivated through years of experience. Trustworthiness in the realm of earth wire welding also involves rigorous testing and inspection. After the welding process, the integrity of each weld must be verified through a series of tests, including visual inspections and electrical continuity tests. These assessments confirm that the earth wire is correctly integrated into the system, offering immediate feedback on the quality of the work done. Institutions and companies responsible for these systems often rely on certified professionals who demonstrate authoritative knowledge of industry standards and regulations. Professionalism in welding earth wires extends beyond technical skill and into the realm of accountability and safety. Certified welders adhere to strict safety protocols to protect themselves and others on-site. They wear appropriate protective gear, understand the hazards of working with high-temperature reactions, and are trained to respond to emergencies swiftly and effectively. In addition, the environmental impact of welding processes must be considered. Leading companies are now looking at eco-friendly options, such as low-emission fluxes and sustainable materials that do not sacrifice quality or performance. By doing so, they not only meet regulatory requirements but also contribute positively to environmental sustainability. In conclusion, the process of welding earth wires is a specialized skill that requires a balance of technical expertise, practical experience, and a commitment to safety and quality assurance. As industries advance, the demand for skilled professionals in this area grows, emphasizing the need for individuals who not only exhibit expertise and authority but also maintain the trust and confidence of their clients. Such dedication to excellence ensures that welding earth wires continues to be an indispensable part of maintaining the safety and integrity of electrical systems worldwide.

In field applications, the expertise of the welder is paramount. Experienced welders can adapt to varying conditions, whether it be harsh weather, confined spaces, or challenging positions. They know how to manipulate their tools and materials with precision, ensuring that each weld is executed flawlessly. This adaptability is rooted in a deep understanding of both the theoretical and practical aspects of welding, cultivated through years of experience. Trustworthiness in the realm of earth wire welding also involves rigorous testing and inspection. After the welding process, the integrity of each weld must be verified through a series of tests, including visual inspections and electrical continuity tests. These assessments confirm that the earth wire is correctly integrated into the system, offering immediate feedback on the quality of the work done. Institutions and companies responsible for these systems often rely on certified professionals who demonstrate authoritative knowledge of industry standards and regulations. Professionalism in welding earth wires extends beyond technical skill and into the realm of accountability and safety. Certified welders adhere to strict safety protocols to protect themselves and others on-site. They wear appropriate protective gear, understand the hazards of working with high-temperature reactions, and are trained to respond to emergencies swiftly and effectively. In addition, the environmental impact of welding processes must be considered. Leading companies are now looking at eco-friendly options, such as low-emission fluxes and sustainable materials that do not sacrifice quality or performance. By doing so, they not only meet regulatory requirements but also contribute positively to environmental sustainability. In conclusion, the process of welding earth wires is a specialized skill that requires a balance of technical expertise, practical experience, and a commitment to safety and quality assurance. As industries advance, the demand for skilled professionals in this area grows, emphasizing the need for individuals who not only exhibit expertise and authority but also maintain the trust and confidence of their clients. Such dedication to excellence ensures that welding earth wires continues to be an indispensable part of maintaining the safety and integrity of electrical systems worldwide.

Next:

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

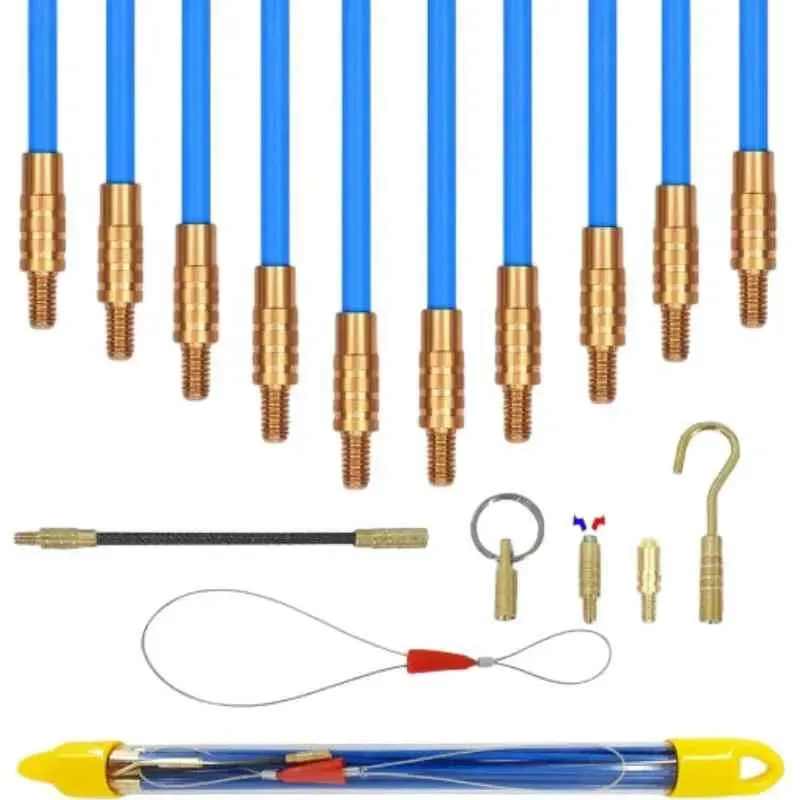

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy