Aug . 14, 2025 02:40 Back to list

Expert Cable Pulling Tools: Winches, Socks & Rollers

Navigating the Landscape of Cable Pulling Tools and Equipment

In the dynamic world of industrial infrastructure, the efficiency and safety of cable installation are paramount. This involves a specialized array of equipment collectively known as cable pulling tools. These innovative solutions are indispensable for laying power, telecommunications, and control cables across diverse environments, from congested urban conduits to sprawling industrial complexes. The demand for robust, reliable, and technologically advanced cable pulling solutions continues to grow, driven by global urbanization, digital transformation, and the expansion of renewable energy grids. Understanding the nuances of these tools, their manufacturing precision, and their strategic application is crucial for project managers and technical personnel aiming to optimize operational efficiency and ensure long-term system integrity.

The industry is currently experiencing significant trends, including a strong emphasis on automation, enhanced safety features, and the development of lightweight yet durable materials. Manufacturers are increasingly integrating smart technologies into their cable pulling equipment to provide real-time data on pulling forces, distances, and potential obstructions, thereby minimizing risks and maximizing productivity. Furthermore, there's a growing demand for eco-friendly and energy-efficient solutions that reduce the environmental footprint of large-scale cable installation projects. These trends collectively underscore a shift towards more sophisticated and user-centric cable pulling methodologies designed to meet the rigorous demands of modern infrastructure development.

Manufacturing Excellence: The Craft Behind Cable Pulling Tools

The production of high-performance cable pulling tools involves a meticulous multi-stage manufacturing process, ensuring durability, precision, and operational safety. Key components, such as those found in the Cable Drum Roller Jack, typically begin with the selection of premium materials like high-grade alloy steels (e.g., 40Cr, 45# steel) or robust aluminum alloys, chosen for their superior strength-to-weight ratio and corrosion resistance. The initial phase often involves precision casting or hot forging to achieve the basic structural integrity of components, forming complex geometries that would be difficult to machine directly from solid stock. This foundational step ensures optimal material grain structure and reduces internal stresses, which are critical for tools subjected to significant mechanical loads.

Following initial shaping, components undergo advanced CNC machining processes. Computer Numerical Control (CNC) ensures unparalleled dimensional accuracy and consistency, critical for the smooth operation and interoperability of moving parts like rollers and winches. Surface treatments, such as powder coating, galvanization, or electroplating, are then applied to enhance durability, provide anti-corrosion properties suitable for harsh environments (e.g., petrochemical and marine applications), and extend the product’s service life, often exceeding 10-15 years under typical operating conditions. Strict adherence to international standards like ISO 9001 for quality management and ANSI/ASME standards for mechanical components ensures that every tool meets rigorous performance and safety benchmarks, providing critical advantages in sectors such as metallurgy, mining, power transmission, and municipal water/drainage systems where reliability and safety are non-negotiable.

Technical Parameters and Performance Benchmarks

The performance of cable pulling equipment is defined by a range of critical technical parameters. These specifications are vital for engineers and procurement specialists to select the right tools for specific project demands, ensuring optimal efficiency and safety. Key parameters include maximum pulling force, applicable cable diameter range, drum capacity (for winches), material strength (e.g., yield strength, tensile strength), and operational speed. For instance, a high-capacity cable pulling winch might offer a continuous pulling force of 50 kN and a maximum speed of 20 meters per minute, making it suitable for heavy-duty power cable installations.

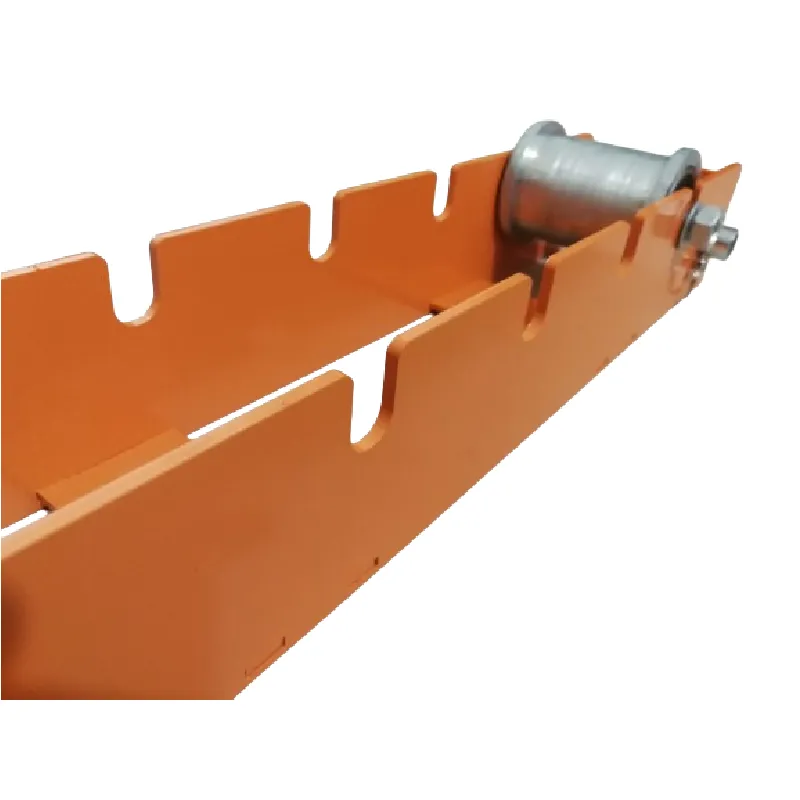

Specialized components like cable pulling sock (also known as cable grips or stockings) are engineered with specific breaking strengths, typically ranging from 2,000 kg to over 10,000 kg, depending on the cable size and pulling requirements. Similarly, cable tray rollers are designed with varying load capacities and roller widths to accommodate different cable types and weights, reducing friction and preventing damage during installation. Below is a comparative table illustrating common technical parameters across different categories of cable pulling tools, providing a consolidated view for technical evaluation.

Comparative Technical Parameters for Cable Pulling Tools

| Tool Type | Key Parameter 1 | Key Parameter 2 | Typical Range |

|---|---|---|---|

| Cable Pulling Winch | Max Pulling Force | Pulling Speed | 10-150 kN, 5-30 m/min |

| Cable Drum Roller Jack | Max Load Capacity | Drum Diameter Range | 5-20 tons, 800-2500 mm |

| Cable Pulling Sock | Breaking Strength | Cable Diameter Fit | 2-15 tons, 10-150 mm |

| Cable Tray Roller | Load Bearing Capacity | Roller Width | 200-500 kg, 50-200 mm |

These specifications are crucial for ensuring that the chosen cable pulling tools align with the specific demands of a project, preventing overloading, cable damage, or operational delays. The integration of high-strength components and advanced engineering principles allows for optimal force distribution and reduced friction, leading to significant energy savings during large-scale installations.

Diverse Applications and Key Advantages

The versatility of cable pulling tools makes them indispensable across a multitude of industries. In power transmission and distribution, they are critical for installing large-diameter underground cables, overhead lines, and substation wiring. The telecommunications sector relies heavily on them for deploying fiber optic networks and data cables in complex urban conduits. Beyond these, industries such as petrochemicals, metallurgy, mining, and railway infrastructure utilize these tools for installing control, instrumentation, and power cables in challenging, often corrosive, environments. For instance, the robust construction and anti-corrosion treatments of Cable Drum Roller Jacks make them ideal for outdoor use and in areas with high humidity or chemical exposure.

The technical advantages of modern cable pulling equipment are multifaceted. Firstly, they significantly reduce the manual labor required, enhancing worker safety and mitigating the risk of injuries associated with heavy lifting and strenuous pulling. Secondly, precise control over pulling force minimizes stress on the cable, preventing costly damage such as kinking, stretching, or insulation abrasion, which can lead to premature system failure. Thirdly, high-efficiency designs, such as low-friction cable tray rollers and geared cable pulling winches, contribute to notable energy savings during installation, particularly on long runs. This translates into lower operational costs and reduced environmental impact. Our clients frequently report a 30% reduction in installation time and a 15% decrease in associated energy consumption when using optimized tools.

Manufacturer Comparison and Customization Solutions

When selecting cable pulling tools, discerning the differences between manufacturers is crucial. While many offer standard equipment, leading providers distinguish themselves through material quality, precision engineering, adherence to international safety standards (e.g., CE, RoHS compliance), and comprehensive after-sales support. Established manufacturers often have a longer service history and robust R&D capabilities, enabling them to innovate and adapt to evolving industry needs. For instance, a company with over 15 years of experience in the field will typically offer a broader range of specialized products and a deeper understanding of complex installation challenges, as evidenced by their portfolio of successful application cases.

For unique project requirements, customized solutions in cable pulling equipment are increasingly common. This can involve modifying standard tools to handle specific cable dimensions, unusual pulling paths, or extreme environmental conditions. Customization might include bespoke designs for cable pulling sock to grip irregular cable shapes, or designing specialized cable tray rollers for confined spaces. A dedicated engineering team can work closely with clients to develop tailor-made tools that precisely meet their operational needs, ensuring optimal performance and safety where off-the-shelf solutions fall short. This collaborative approach ensures that even the most challenging cable installation projects can be executed efficiently and securely.

Real-World Application Cases and Client Feedback

The efficacy of cable pulling tools is best demonstrated through successful real-world applications. Consider a recent project involving the installation of 33kV power cables across a 5km underground duct network in a major metropolitan area. Utilizing a high-capacity cable pulling winch along with series of self-aligning cable tray rollers, the project team was able to pull heavy power cables through multiple bends with minimal friction and consistent tension. The use of precisely matched cable pulling sock ensured secure gripping without damaging the cable's outer sheath. This streamlined approach resulted in the completion of the pulling phase 25% ahead of schedule, showcasing the immense operational benefits of integrated, high-quality cable pulling solutions.

Another notable case involved a petrochemical facility upgrading its control system, requiring the installation of thousands of meters of multi-core instrumentation cables through existing, often challenging, conduit runs. The deployment of compact yet powerful cable pulling tools, including specialized Cable Drum Roller Jacks for managing large cable reels in tight spaces, proved invaluable. Feedback from the site engineers highlighted the ease of setup and the robust performance under continuous operation, significantly reducing downtime. "The precision and durability of these cable pulling equipment were instrumental in our ability to meet stringent deadlines in a high-risk environment," commented the lead engineer from the petrochemical project. These testimonials reinforce the trust and reliability our products offer.

Frequently Asked Questions (FAQs)

Q1: What is the typical lead time for custom cable pulling tools?

A1: The lead time for customized cable pulling tools depends on the complexity of the design and specific material requirements. Generally, after the design approval, manufacturing and delivery can range from 4 to 8 weeks. For standard cable pulling equipment, the delivery cycle is typically 1-2 weeks, subject to stock availability and shipping logistics. Our dedicated customer support team provides real-time updates on order status and estimated delivery dates.

Q2: What warranty and after-sales support are offered for these products?

A2: All our cable pulling tools come with a standard 12-month warranty covering manufacturing defects and material failures under normal operating conditions. We are committed to providing comprehensive after-sales support, including technical assistance, spare parts availability, and maintenance guidance. Our technical support team is available via phone and email to address any operational queries or troubleshooting needs, ensuring uninterrupted performance and longevity of your cable pulling equipment.

Q3: How do these tools contribute to energy saving and anti-corrosion?

A3: Our cable pulling tools are designed with features that contribute to both energy efficiency and corrosion resistance. Components like cable tray rollers and winches incorporate high-efficiency bearings and optimized gear ratios, reducing friction and the power required for pulling, thus saving energy. For anti-corrosion, critical parts are often made from marine-grade aluminum or stainless steel, and surfaces are treated with advanced powder coatings or galvanization processes. These measures significantly extend the service life of the tools, even in highly corrosive industrial or outdoor environments, ensuring long-term reliability and reducing the need for frequent replacements.

References

- IEEE. (2022). "Standards for Cable Installation and Management in Industrial Environments."

- Journal of Construction Engineering and Management. (2023). "Advancements in Mechanized Cable Laying Technologies."

- National Electrical Code (NEC) Handbook. (2020). "Guidelines for Cable Pulling Tensions and Radii."

- Materials Science and Engineering: A. (2021). "Corrosion Resistance of Alloy Steels in Industrial Applications."

- Power Engineering International. (2023). "Optimizing Cable Installation for Renewable Energy Projects."

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025