Sep . 12, 2025 09:20 Back to list

Heavy-Duty Cable Tray Pulley - Smooth & Efficient Cable Installation

The Indispensable Role of the Cable Tray Pulley in Modern Industrial Infrastructure

In the intricate landscape of industrial infrastructure, efficient and safe cable management is paramount. The Cable Tray Pulley stands as a critical component, facilitating the smooth and damage-free installation of power, control, and communication cables across diverse applications. These specialized pulleys are engineered to support and guide cables during installation in cable tray systems, preventing kinks, abrasions, and excessive tension that can compromise cable integrity and performance. As a B2B decision-maker or engineering professional, understanding the technical nuances, application benefits, and strategic advantages of high-quality Cable Tray Pulleys is essential for optimizing project timelines, ensuring operational safety, and maximizing the longevity of your cabling investments.

This article delves into the core aspects of Cable Tray Pulleys, from their manufacturing excellence and technical specifications to their vital role in various industries, aiming to provide a comprehensive overview for informed procurement and implementation decisions.

Industry Trends and Market Evolution

The demand for robust and efficient cable management solutions is continuously evolving, driven by several key industry trends. There's a growing emphasis on high-performance materials capable of withstanding extreme environmental conditions, such as corrosive atmospheres in petrochemical facilities or fluctuating temperatures in renewable energy projects. Automation in construction and maintenance further necessitates Cable Tray Pulleys with advanced bearing systems that reduce friction and allow for faster, more precise cable pulls. Sustainability is also a driving factor, with manufacturers increasingly focusing on designs that extend product service life, minimize waste, and contribute to energy efficiency by reducing the power required for cable installation.

The integration of smart technologies, though nascent, is also emerging, with possibilities for real-time load monitoring and predictive maintenance for heavy-duty systems. These trends highlight the shift towards more intelligent, durable, and environmentally conscious solutions in cable installation.

Technical Specifications and Parameters

The performance of a Cable Tray Pulley is defined by a meticulous set of technical specifications. These parameters ensure compatibility, safety, and operational efficiency for specific project requirements. Key considerations include the sheave diameter, which influences the minimum bending radius of the cable; the Safe Working Load (SWL), indicating the maximum load the pulley can safely bear; and the material composition, dictating its resistance to corrosion, wear, and environmental factors. Below is a representative table outlining critical product specifications:

| Parameter | Specification/Value | Technical Details |

|---|---|---|

| Material | High-Tensile Aluminum Alloy (6061-T6), Stainless Steel (304/316), Engineered Polymer (HDPE/Nylon) | Lightweight, corrosion-resistant, high strength-to-weight ratio. Suitable for varied environments. |

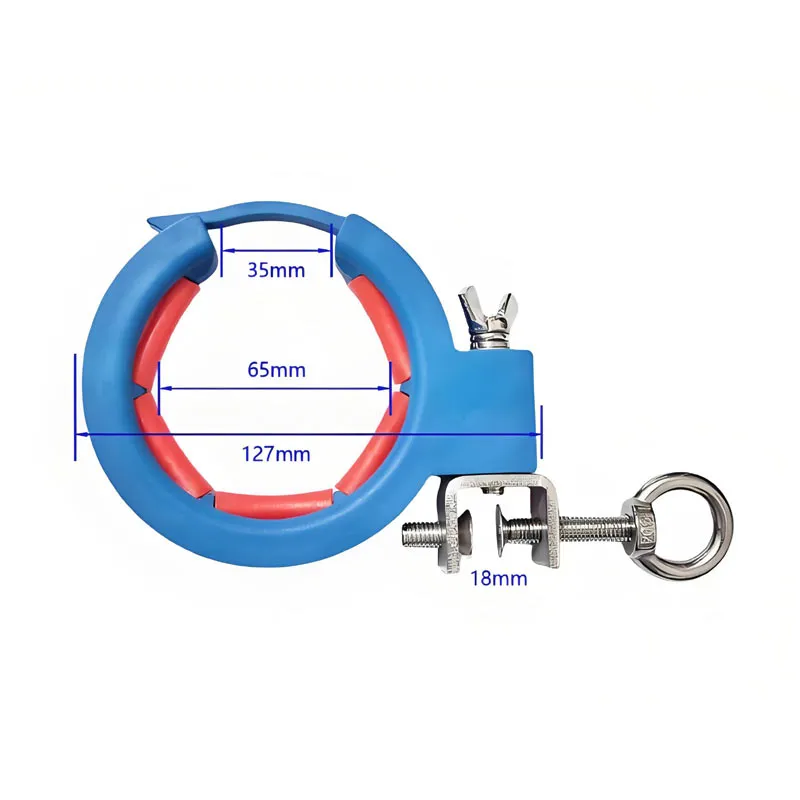

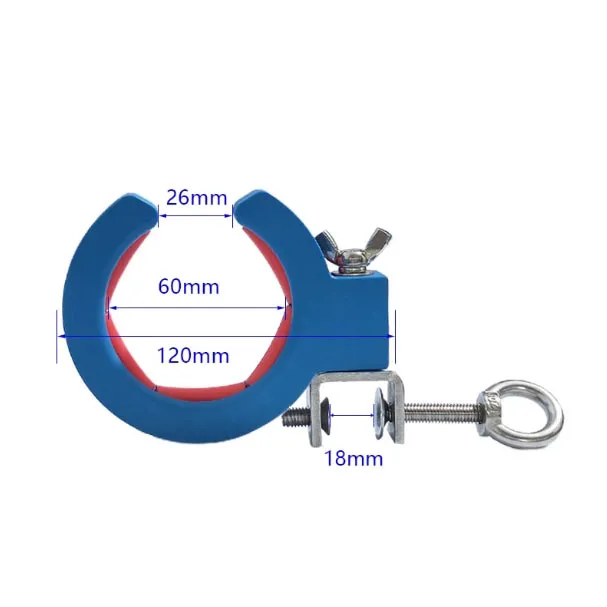

| Sheave Diameter | 75mm to 300mm (3" to 12") | Optimized for various cable bending radii, preventing internal damage and stress. |

| Safe Working Load (SWL) | 200 kg to 2000 kg (440 lbs to 4400 lbs) | Critical safety parameter, typically with a 4:1 safety factor for Ultimate Breaking Strength (UBS). |

| Bearing Type | Precision Sealed Ball Bearings (e.g., ABEC-5) | Minimizes friction, ensures smooth operation, requires minimal maintenance, extends service life. |

| Operating Temperature | -40°C to +80°C (-40°F to +176°F) | Ensures reliable performance in extreme industrial environments. |

| Surface Finish | Anodized, Galvanized, Powder Coated | Enhances corrosion resistance and durability, protects against environmental degradation. |

| Mounting Options | Clamp-on, Bolt-on, Magnetic Base | Versatility for various cable tray types and installation scenarios. |

| Compliance Standards | ISO 9001:2015, CE, ANSI B30.20 | Ensures adherence to international quality management and safety standards. |

A thorough understanding of these specifications is vital for selecting the appropriate Cable Tray Pulley for any given project, ensuring optimal performance and safety.

Diverse Application Scenarios

The utility of the Cable Tray Pulley extends across a broad spectrum of heavy industries, reflecting its adaptability and critical function in complex cabling operations. From the extreme conditions of offshore oil rigs to the precision demands of data centers, these pulleys are indispensable. They are routinely deployed in:

- Petrochemical and Oil & Gas Facilities: Handling large diameter, heavy-duty armored cables in environments prone to corrosion and hazardous conditions.

- Power Generation Plants (Nuclear, Thermal, Renewable): Facilitating the installation of critical power transmission and control cables with minimal disruption.

- Mining Operations: Guiding robust cables through challenging underground or open-pit terrains, minimizing wear and tear.

- Shipbuilding and Marine Applications: Employing specialized marine-grade pulleys for cable runs in corrosive saltwater environments.

- Data Centers and Telecommunications: Ensuring delicate fiber optic and network cables are installed without micro-bends or tensile stress.

- Heavy Construction and Infrastructure Projects: Supporting the deployment of extensive cabling networks for tunnels, bridges, and large commercial complexes.

- Water Supply & Drainage Systems: For control and power cabling in damp or subterranean environments.

Each scenario underscores the need for application-specific pulley designs that guarantee operational continuity and adherence to stringent safety protocols.

Technical Advantages and Performance Benefits

Investing in high-quality Cable Tray Pulley systems yields significant returns in terms of efficiency, safety, and asset protection. The primary advantages include:

- Reduced Cable Damage: Precision-engineered sheaves and smooth-running bearings prevent kinks, abrasions, and excessive tension, thereby extending the service life of expensive cables.

- Enhanced Installation Efficiency: By minimizing friction and enabling smoother pulls, Cable Tray Pulleys significantly reduce installation time and labor costs, especially for long cable runs or heavy cables.

- Improved Safety: Controlled cable pulling reduces the risk of accidents from uncontrolled cable movement or manual strain, contributing to a safer work environment.

- Corrosion Resistance: Utilizing materials like galvanized steel, anodized aluminum, or marine-grade stainless steel ensures longevity and reliable performance even in harsh, corrosive industrial settings.

- Energy Saving: The reduction in friction during cable pulling translates to lower power consumption for pulling equipment, leading to tangible energy savings over large-scale projects.

- Optimal Cable Routing: Strategic placement of pulleys ensures cables are laid correctly within the tray, adhering to design specifications and preventing future maintenance issues.

These advantages collectively underscore the strategic importance of specifying the right Cable Tray Pulley for any industrial cabling project.

Manufacturing Process Flow for Superior Quality

The production of a high-performance Cable Tray Pulley involves a series of meticulously controlled stages, ensuring durability, precision, and compliance with international standards. Our process emphasizes advanced manufacturing techniques and rigorous quality control:

- Material Selection: Begins with sourcing premium-grade materials, typically high-tensile aluminum alloys (e.g., 6061-T6 for lightweight strength), stainless steel (e.g., 304 or 316 for superior corrosion resistance), or specialized engineered polymers (e.g., ultra-high molecular weight polyethylene, UHMW-PE, for excellent wear resistance and low friction). Material certificates confirming chemical composition and mechanical properties are mandatory.

- Component Forming (Casting/Forging/Extrusion): Depending on the material and design, sheave and frame components undergo processes such as precision casting for complex shapes, forging for enhanced strength and grain structure, or extrusion for aluminum profiles. This ensures initial structural integrity.

- CNC Machining: State-of-the-art CNC (Computer Numerical Control) machining centers are employed for high-precision finishing. This includes machining the sheave groove to exact radii, creating precise bearing seats, and detailing mounting points on the frame. Tolerances are typically held to ±0.05mm to ensure optimal fit and smooth operation.

- Surface Treatment: Components undergo surface treatment to enhance durability and corrosion resistance. Options include hot-dip galvanization for steel, anodizing for aluminum to create a protective oxide layer, or powder coating for added chemical resistance and aesthetics. This step significantly contributes to the pulley's service life, especially in harsh environments.

- Bearing Integration: High-quality, sealed ball bearings (e.g., deep groove, radial) are carefully integrated into the sheave. These bearings are chosen for their low friction coefficient and ability to withstand significant radial and axial loads, ensuring frictionless cable travel and long-term reliability. Lubrication is typically factory-sealed for maintenance-free operation.

- Assembly: The frame, sheave, bearings, and axle are meticulously assembled by skilled technicians. All fasteners are torqued to specifications, and moving parts are checked for smooth, unhindered movement.

- Quality Control & Testing: Each Cable Tray Pulley undergoes a multi-stage quality control process. This includes dimensional inspection, material composition verification (e.g., XRF analysis), non-destructive testing (NDT) such as ultrasonic or magnetic particle inspection for critical components, and functional testing. Load testing is performed to verify the Safe Working Load (SWL) and Ultimate Breaking Strength (UBS), typically to a 4:1 safety factor. Operational smoothness, deflection angles under load, and bearing friction are also assessed.

- Packaging & Certification: Products are securely packaged to prevent transit damage and accompanied by certifications of compliance (e.g., ISO 9001:2015, CE marking, ASTM F2276 for cable tray supports).

Our Cable Tray Pulley products are designed for an extended service life, typically exceeding 5-10 years under normal operating conditions, primarily targeting industries like petrochemical, metallurgy, power generation, and water supply & drainage where reliability is paramount. The emphasis on corrosion resistance and energy-saving design directly translates into lower operational costs and enhanced project safety in typical application scenarios.

Vendor Comparison: Choosing the Right Partner

Selecting the right supplier for Cable Tray Pulley systems is a strategic decision that impacts project efficiency, safety, and long-term operational costs. Key differentiators among vendors often include material quality, manufacturing precision, adherence to international standards, and post-sales support. Below is a comparative overview of typical vendor offerings:

| Feature | Bilopowtel (Our Offerings) | Global Cable Solutions (Competitor A) | Industrial Pulley Innovations (Competitor B) |

|---|---|---|---|

| Material Quality | Premium Aluminum (6061-T6), SS316, UHMW-PE. Full material traceability. | Standard Aluminum (6063), SS304. Limited traceability. | Galvanized Steel, Nylon. Basic material certifications. |

| Load Capacity Range | SWL up to 2000 kg. Exceeds industry safety factors. | SWL up to 1500 kg. Meets standard safety factors. | SWL up to 1000 kg. Basic safety compliance. |

| Certifications | ISO 9001:2015, CE, ANSI B30.20, DNV (Marine options). | ISO 9001, CE. | ISO 9001. |

| Customization Options | Full bespoke design, material, finish, load rating adjustments. | Limited modifications to standard products. | Standard catalogue items only. |

| Warranty | Comprehensive 5-year warranty. | 2-year standard warranty. | 1-year limited warranty. |

| After-Sales Support | Dedicated technical support, on-site assistance available. | Email/phone support during business hours. | Basic online support. |

This comparison highlights the benefits of partnering with a manufacturer that prioritizes superior materials, stringent quality control, and comprehensive customer support, ensuring that your investment in a Cable Tray Pulley system delivers maximum value.

Customized Solutions for Unique Challenges

Recognizing that no two industrial projects are identical, Bilopowtel offers highly customized Cable Tray Pulley solutions. Our engineering team collaborates closely with clients to understand specific project parameters, environmental conditions, and cable types. This enables the design and manufacture of bespoke pulleys that precisely meet unique requirements, rather than relying on off-the-shelf components that may compromise performance or safety.

- Material Adaptation: Custom alloys or polymers for extreme temperatures, chemical exposure, or specific non-conductive requirements.

- Load & Size Modifications: Pulleys designed for exceptionally heavy cables or unusually tight bend radii.

- Specialized Coatings & Finishes: Coatings for marine applications, UV resistance, or specific aesthetic requirements.

- Unique Mounting Systems: Bespoke clamps or fixtures for non-standard cable tray designs or structural interfaces.

- Integrated Sensing: For projects requiring real-time tension monitoring or automated cable feeding.

Our expertise in engineering and manufacturing allows us to deliver optimized solutions that address the most challenging cable installation scenarios, ensuring seamless integration and superior performance.

Application Case Studies: Proven Performance

Our commitment to quality and technical excellence is demonstrated through successful deployments in demanding industrial environments:

Case Study 1: Petrochemical Plant Expansion (Middle East)

Challenge: Installation of 33kV power cables, each weighing over 15 kg/meter, across 2km of complex cable trays with multiple bends within an active petrochemical facility. The corrosive atmosphere demanded highly resilient equipment, and safety regulations required minimal manual handling and absolute prevention of cable damage.

Solution: Bilopowtel supplied custom-designed Cable Tray Pulley systems featuring SS316 frames, UHMW-PE sheaves (for optimal chemical resistance and low friction), and heavy-duty sealed bearings. These pulleys were rated for an SWL of 1000 kg per unit and designed with quick-release clamping mechanisms for efficient deployment.

Result: The client reported a 35% reduction in installation time compared to previous projects and zero instances of cable jacket damage or internal conductor stress. The corrosion-resistant design ensured long-term reliability in the aggressive environment, validating the choice of specialized materials and precision engineering.

Case Study 2: Offshore Wind Farm Inter-Array Cabling (North Sea)

Challenge: Laying heavy-duty subsea inter-array cables (200mm diameter) into transition piece cable trays on offshore wind turbines. The project faced severe weather conditions, tight installation windows, and an extremely corrosive marine environment, necessitating equipment capable of extreme resilience and high load capacity.

Solution: Bilopowtel engineered a series of large-diameter, marine-grade Cable Tray Pulley units constructed from duplex stainless steel with oversized, triple-sealed ceramic bearings. Each unit was designed with an SWL of 2500 kg and integrated with specialized anti-rotation features to manage dynamic loads during offshore operations.

Result: The custom pulleys facilitated the successful deployment of over 50km of inter-array cables, significantly reducing the risk of fatigue damage to the cables during handling. The robust design withstood the harsh marine environment, contributing to the project's adherence to stringent safety and environmental standards. The client specifically praised the pulleys' smooth operation, which saved critical hours during the limited weather windows.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Establishing trust with our B2B partners is fundamental. Bilopowtel is committed to transparency and reliable service delivery.

Frequently Asked Questions (FAQ)

- Q1: How do I select the correct Cable Tray Pulley for my project?

A1: Selection depends on cable diameter and weight, required bend radius, environmental conditions (e.g., corrosive, temperature extremes), and the specific cable tray system. Our technical sales team can provide expert guidance based on your project specifications. - Q2: What maintenance is required for your Cable Tray Pulleys?

A2: Our pulleys are designed for minimal maintenance. Key steps include periodic visual inspection for wear, damage, or corrosion, and ensuring bearings remain free of debris. Sealed bearings typically require no lubrication for their service life. - Q3: Are your pulleys certified for use in hazardous environments (e.g., ATEX zones)?

A3: Yes, we offer specific models and custom solutions that comply with ATEX/IECEx directives for use in explosive atmospheres. Please specify your zone requirements during inquiry. - Q4: What is the typical lifespan of a Bilopowtel Cable Tray Pulley?

A4: With proper selection, installation, and minimal maintenance, our Cable Tray Pulley products are engineered for a service life exceeding 5-10 years, even under demanding industrial use.

Lead Time & Fulfillment

For standard Cable Tray Pulley models, our typical lead time is 2-4 weeks, depending on order volume and current stock. Customized solutions may require 6-10 weeks for design, prototyping, manufacturing, and testing. We maintain transparent communication regarding order status and shipment schedules, ensuring timely project execution.

Warranty Commitments

Bilopowtel stands behind the quality of its products with a comprehensive 5-year warranty against manufacturing defects and material failures under normal operating conditions. This commitment reflects our confidence in our engineering and production processes, providing our clients with peace of mind and long-term assurance.

Customer Support

Our dedicated customer support team and technical experts are available to assist with product selection, installation guidance, troubleshooting, and any post-sales inquiries. We offer multi-channel support via phone, email, and live chat, ensuring prompt and effective resolution to maintain your operational continuity. For complex projects, on-site technical assistance can also be arranged.

Conclusion

The Cable Tray Pulley is far more than a simple accessory; it is a meticulously engineered component that underpins the safety, efficiency, and longevity of critical industrial cabling infrastructure. From material selection and precision manufacturing to rigorous testing and versatile application, every aspect of a high-quality pulley system is designed to meet the exacting demands of modern industrial environments. By understanding the detailed technical specifications, leveraging customized solutions, and partnering with a trusted vendor like Bilopowtel, B2B decision-makers and engineers can ensure optimal cable installation, minimize operational risks, and achieve superior long-term performance for their projects.

Our commitment to innovation, quality, and comprehensive customer support positions us as a leader in providing advanced cable management solutions, contributing to the successful and sustainable development of global industrial infrastructure.

References

- ISO.org - International Organization for Standardization. ISO 9001:2015 Quality management systems — Requirements.

- ANSI.org - American National Standards Institute. ANSI B30.20: Below-the-Hook Lifting Devices.

- ASTM.org - ASTM International. ASTM F2276: Standard Specification for Cable Tray Supports.

- DNV.com - DNV GL. Rules for Classification of Ships.

- NACE.org - NACE International (now AMPP). Standards for corrosion prevention and control.

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025