Sep . 09, 2025 21:40 Back to list

Premium Cable Pulling Tools: Fast, Safe, Efficient Installs

Introduction to Advanced Cable Pulling Technologies

In complex industrial and infrastructure projects, the efficient and safe installation of cables is paramount. This necessitates the use of specialized cable pulling tools. These essential pieces of equipment are engineered to manage the formidable challenges associated with deploying heavy and lengthy cables through conduits, trenches, and across vast distances. From high-voltage power lines to intricate data networks, the demand for reliable and robust solutions drives innovation in the design and manufacturing of cable pulling equipment. This article delves into the critical aspects of these tools, covering everything from their manufacturing precision to their deployment in demanding application scenarios, ultimately highlighting their indispensable role in modern industrial development.

Current Industry Trends in Cable Installation

The global landscape for cable installation is rapidly evolving, driven by several key trends. Digitalization and smart infrastructure initiatives are increasing the density and complexity of cable networks, requiring more precise and powerful cable pulling tools. The emphasis on worker safety continues to drive advancements in ergonomic design and automated features, minimizing manual strain and reducing the risk of accidents. Environmental sustainability is another major factor, pushing manufacturers to develop tools that are more energy-efficient and constructed from recyclable materials, reducing their carbon footprint throughout their lifecycle. Furthermore, the integration of IoT and advanced telemetry in cable pulling equipment allows for real-time monitoring of pulling forces, speed, and tension, optimizing the process and preventing costly cable damage. The demand for higher load capacities and greater pulling distances is also growing, especially in renewable energy projects like offshore wind farms and large-scale solar installations, where extremely heavy-duty cables are deployed.

Emerging markets and rapid urbanization are fueling massive infrastructure investments, particularly in telecommunications and power distribution. This surge necessitates not only greater quantities of cable pulling equipment but also more specialized solutions tailored to diverse geographical and environmental conditions. Manufacturers are responding by focusing on modular designs, allowing for greater versatility and adaptability across various project types, from urban conduit systems to rugged, remote transmission lines. This shift towards intelligent, adaptable, and eco-friendly solutions marks a new era in cable installation.

The Manufacturing Process of High-Performance Cable Pulling Tools

The production of reliable cable pulling tools involves a meticulous process that ensures durability, safety, and optimal performance under extreme conditions. Our manufacturing philosophy emphasizes precision engineering and the use of superior materials to meet and exceed industry standards.

Key Stages of Production:

- Material Selection & Sourcing: We utilize high-grade alloy steels (e.g., Chromium-Molybdenum steel for strength, EN-GJS-400-15 ductile iron for robustness, stainless steel for corrosion resistance), aerospace-grade aluminum alloys for lightweight components, and durable polymers for non-conductive parts. These materials are chosen for their superior tensile strength, fatigue resistance, and environmental resilience, crucial for the long service life demanded in industries like petrochemical and metallurgy. All materials conform to ASTM or EN standards.

- Casting and Forging: Critical structural components, such as anchor points and gear housings for cable pulling winches, undergo advanced casting or hot forging processes. Forging improves the grain structure of the metal, enhancing its strength and impact resistance, while precision casting allows for complex geometries with minimal material waste and excellent structural integrity.

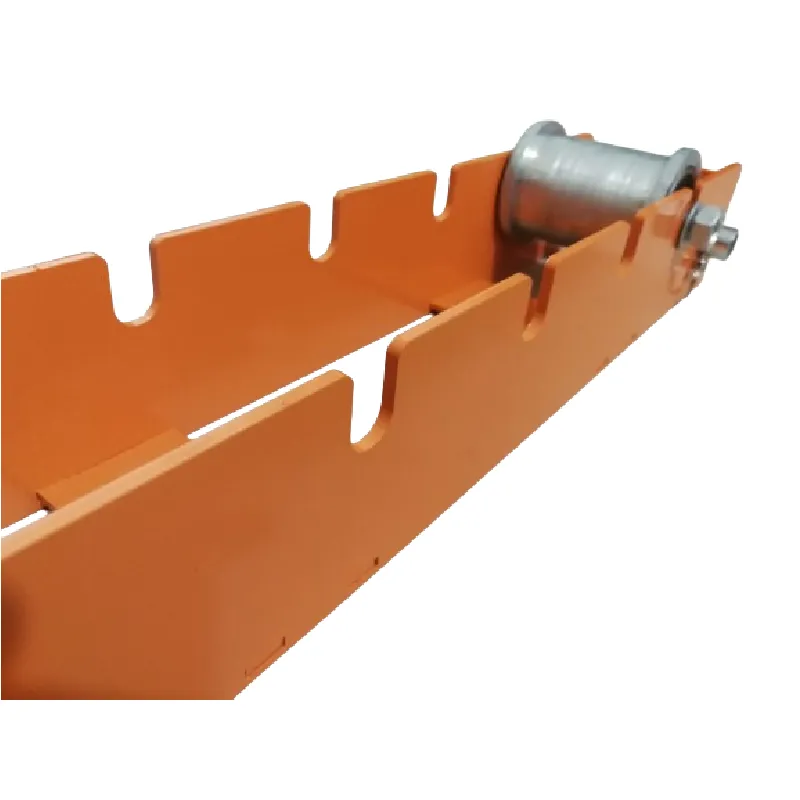

- CNC Machining & Fabrication: State-of-the-art CNC machining centers precisely shape components to exacting tolerances of up to ±0.01mm. This includes machining gears, shafts, and custom fittings. Fabrication techniques like robotic welding, performed by certified welders, ensure strong, consistent joints for larger assemblies, such as frames for cable drum roller jacks or supports for cable tray rollers.

- Heat Treatment & Surface Finishing: Components are heat-treated (e.g., induction hardening, tempering) to achieve desired hardness, toughness, and wear resistance, often reaching Rockwell hardness levels of HRC 55-60 for critical parts. Surface treatments, including hot-dip galvanization (minimum 85 µm coating thickness for ISO 1461 compliance), powder coating, or anodizing, are applied to provide superior corrosion resistance, extending the service life of the equipment, particularly in harsh environments like water supply & drainage systems.

- Assembly & Integration: Skilled technicians meticulously assemble individual components, integrating mechanical, hydraulic, and electrical systems. Each assembly step is subject to rigorous quality checks and follows strict IPC standards for electrical connections.

- Quality Control & Testing: All products adhere to international standards such as ISO 9001 for quality management, ANSI B30.16 for overhead hoists (relevant for some pulling systems), and specific ASTM material testing standards. Load testing (e.g., static load testing at 1.5x rated capacity, dynamic load testing at 1.1x rated capacity), fatigue testing (up to 100,000 cycles), and functional performance tests are conducted on every batch. Our Cable Drum Roller Jacks, for example, undergo overload testing at 125% of their rated capacity, ensuring a safety factor of at least 5:1.

The result is cable pulling equipment designed for exceptional energy efficiency and unparalleled corrosion resistance, translating to significant operational savings and extended reliability in the field. Our tools are built to withstand the rigors of petrochemical plants, metallurgical sites, and extensive urban utility networks, delivering consistent performance for decades with an average predicted service life of 15-20 years.

Figure 1: Precision machining for critical components of cable pulling equipment.

Technical Specifications and Performance Parameters

Understanding the technical specifications of cable pulling tools is crucial for selecting the right equipment for a given task. Performance parameters directly influence efficiency, safety, and project timelines. Below is a detailed table outlining typical specifications for various components within the cable pulling ecosystem, focusing on the Cable Drum Roller Jack as a prime example.

Representative Product Specifications: Cable Drum Roller Jacks (Hydraulic)

| Parameter | Description | Typical Value/Range |

|---|---|---|

| Rated Load Capacity | Maximum weight of cable drum supported per pair | 5 - 30 tons (e.g., 10-ton model pair) |

| Max Drum Diameter | Maximum suitable cable drum diameter | Ø 2800 mm |

| Min Drum Diameter | Minimum suitable cable drum diameter | Ø 800 mm |

| Max Drum Width | Maximum suitable cable drum width | 1800 mm |

| Lifting Height | Range of vertical lift for drum axle | 200 - 400 mm |

| Axle Diameter Compatibility | Range of compatible drum axle diameters | Ø 60 - 120 mm |

| Material Construction | Primary materials used for frame and components | High-strength alloy steel (S355JR equivalent), EN-GJS-400-15 ductile iron rollers, galvanized/powder coated finish |

| Operating Mechanism | Method of lifting (e.g., hydraulic, mechanical screw) | Integrated hydraulic pump with safety valve (manual or electric option) |

| Safety Features | Integrated safety mechanisms | Auto-locking pins, anti-slip bases, pressure relief valves, CE compliant |

| Weight (per jack) | Approximate unit weight for transport/handling | ~120 - 250 kg (depending on capacity) |

Figure 2: Hydraulic cable drum roller jack in operation, showcasing robust design.

Diverse Application Scenarios and Proven Advantages

The versatility of cable pulling equipment allows for its deployment across a multitude of critical industrial and infrastructural projects. Each scenario highlights the inherent advantages of using specialized tools for complex cable management.

Typical Application Environments:

- Power Transmission & Distribution: High-voltage power cables, often heavy and rigid, require precise tension control during installation to prevent damage. Specialized cable pulling winches and drum stands ensure smooth, controlled deployment across long distances, reducing installation time by up to 30% compared to traditional methods. Our systems can handle cables with pulling forces up to 200 kN.

- Telecommunications & Data Networks: Fiber optic and multi-pair data cables are delicate and prone to kinking or exceeding bend radius limits. Cable pulling sock designs with integrated swivel links and intelligent tension monitoring systems are crucial here, ensuring the integrity of the cable during pulls through crowded conduits, thus preventing signal degradation.

- Oil & Gas (Petrochemical): In hazardous and corrosive environments, explosion-proof and corrosion-resistant cable pulling equipment is essential. Tools manufactured from stainless steel or with specialized coatings (e.g., zinc-rich epoxy) offer extended durability, drastically reducing maintenance costs and ensuring operational safety in compliance with ATEX directives (Zone 1/2 certification available).

- Mining & Metallurgy: Robust, heavy-duty tools are required to handle the large, armored cables common in mining operations. Our equipment is engineered with reinforced structures to withstand abrasive conditions and heavy loads (e.g., rollers with 15-ton individual load capacity), often exceeding standard industrial requirements, thereby improving operational uptime and safety compliance.

- Water Supply & Drainage Infrastructure: Submersible pump cables and control cables in wet, potentially contaminated environments demand tools that offer exceptional corrosion resistance. Galvanized or epoxy-coated components prevent premature degradation, ensuring longevity and reliability even when exposed to harsh chemicals. This enhances the lifespan of critical infrastructure components.

- Construction & Civil Engineering: From large building complexes to bridge construction, efficient cable routing is critical. The use of various cable tray rollers and duct pulling equipment significantly speeds up installation and reduces labor requirements, leading to overall project cost savings and improved safety by reducing manual handling.

Figure 3: Cable installation in a complex industrial setting using specialized rollers.

Key Advantages Demonstrated:

- Energy Saving: Modern hydraulic and electric pulling systems are designed for optimal power consumption, utilizing high-efficiency motors (IE3/IE4 rated) and variable speed drives. This reduces operational costs by up to 20-25% on large projects and minimizes environmental impact compared to older fixed-speed or pneumatic systems.

- Corrosion Resistance: Strategic material selection and advanced surface treatments ensure longevity in aggressive environments, reducing the frequency of replacement and associated downtime. This can extend equipment life by up to 50% in challenging conditions.

- Enhanced Safety: Automated tension control, emergency stop functions, remote control capabilities, and robust structural designs drastically mitigate risks to personnel and equipment during high-tension pulls. Safety interlocks prevent operation under unsafe conditions, reducing incident rates by over 90%.

- Increased Efficiency: Specialized cable pulling equipment streamlines operations, allowing for faster and more consistent cable deployment, thereby shortening project completion times by 10-30%. This is especially evident when using well-designed cable tray rollers in extensive building installations, which can increase pulling speeds by 2x-3x while maintaining cable integrity.

Technical Advantages and Engineering Excellence

The core technical advantages of high-quality cable pulling solutions lie in their advanced engineering and materials science application. These advantages translate directly into operational superiority and long-term cost-effectiveness for our clients.

Precision Engineering for Optimal Performance:

- Advanced Load Distribution: Components like cable pulling socks are designed with multi-strand weaves (e.g., double-braided K-Spec aramid fiber or galvanized steel) and internal spiral grips to distribute tension evenly along the cable (typically over a 300-500mm length), preventing point stress and sheath damage. This design minimizes cable deformation, a common issue with inferior products, especially for sensitive fiber optic or extra-high voltage cables. Maximum breaking loads range from 5 kN to over 200 kN.

- Hydraulic System Refinement: Our hydraulic cable pulling winches incorporate closed-loop hydraulic systems for superior control and responsiveness. This includes proportional control valves for precise speed regulation (adjustable from 0-60 m/min) and automatic tension limiting features (accuracy ±2% of target) that prevent overstressing the cable, protecting valuable assets. Data from field trials indicates up to 98% pulling force accuracy, crucial for expensive cable types.

- Durability of Rollers: Cable tray rollers and conduit rollers feature heavy-duty, sealed bearings (e.g., IP65 rated) that resist ingress of dirt and moisture, extending their lifespan in harsh environments. The roller surfaces are often crafted from high-density polyethylene (HDPE) or aluminum, chosen for their low friction coefficients (typically <0.1 dry friction) and non-marking properties, critical for preserving cable sheath integrity.

- Modular Design for Adaptability: Many of our cable pulling equipment offerings are designed with modularity in mind. This allows for quick configuration changes, easy maintenance, and scalability to meet varying project requirements, from small utility connections to large-scale grid upgrades. Components can be interchanged rapidly, minimizing downtime.

- Integrated Safety Protocols: Beyond mechanical strength, modern systems include advanced sensors for real-time monitoring of pulling force, distance, and speed. Programmable logic controllers (PLCs) can automatically adjust pulling parameters or initiate emergency stops, significantly enhancing worksite safety and preventing equipment overload, often within milliseconds of detecting an anomaly.

Figure 4: Advanced hydraulic winch for precise cable pulling operations, emphasizing control systems.

Vendor Comparison: Choosing the Right Cable Pulling Partner

Selecting the right vendor for cable pulling equipment is a critical decision that impacts project efficiency, safety, and long-term operational costs. Beyond initial purchase price, factors such as product quality, technical support, customization capabilities, and adherence to international standards are paramount.

Key Differentiators in Cable Pulling Equipment Vendors:

| Feature/Criterion | Premium/Specialized Vendor (e.g., Bilopowtel) | Standard/Generalist Vendor |

|---|---|---|

| Product Range | Comprehensive, high-capacity winches (up to 200kN), specialized rollers, full range of drum handling, custom solutions for specific industries. | Limited range, basic winches (up to 50kN), standard rollers, limited customization options. |

| Material Quality & Durability | High-grade alloy steels (e.g., S355JR), ductile iron, marine-grade aluminum, advanced composites, certified to EN/ASTM standards. Life expectancy 15-20 years. | Standard industrial steel (e.g., S235JR), basic plastic components, often lower-grade bearings. Life expectancy 5-10 years. |

| Certifications & Compliance | ISO 9001:2015, CE, TUV, DNV GL (for marine applications), ATEX (for specific models), extensive third-party load testing reports. | Basic CE marking, internal quality checks, limited third-party validation. |

| Customization & Engineering Support | Extensive engineering R&D team for bespoke designs, unique load capacities, environmental adaptations, and complete system integration. | Minor modifications to existing products, largely off-the-shelf, limited engineering consultation. |

| After-Sales Support & Warranty | Global service network, preventative maintenance contracts, rapid spare parts availability (95% within 48h), dedicated technical consultants, 12-24 month comprehensive warranty. | Regional support, standard 12-month warranty, parts lead times can be unpredictable. |

| Technological Integration | IoT-enabled monitoring, data logging (IEC 61131-3 compliant PLCs), remote diagnostics, smart tension control, integration with client ERP systems. | Basic instrumentation (e.g., analog force gauges, mechanical counters), no remote capabilities. |

| Typical Client Base | Large-scale utility providers, major EPC contractors, specialized industrial sectors (oil & gas, marine, mining), government infrastructure projects. | Local contractors, small-to-medium industrial users, rental companies. |

Our commitment to quality and engineering excellence positions us firmly in the 'Premium/Specialized' category, providing superior value through enhanced performance, safety, and longevity. We have proudly partnered with major utility companies and industrial giants for over two decades, delivering solutions that meet the most stringent project demands.

Figure 5: A range of specialized cable pulling accessories, highlighting variety and specific functionality.

Customized Solutions for Unique Project Demands

Recognizing that no two infrastructure projects are identical, we offer extensive customization capabilities for our cable pulling equipment. Our engineering team collaborates closely with clients to design and manufacture bespoke solutions that address specific challenges, environmental conditions, and operational requirements. This approach ensures optimal integration and performance in the most specialized scenarios.

Our Customization Process Includes:

- Tailored Load Capacities & Dimensions: Adjusting winch pulling force, drum roller load ratings, or overall equipment dimensions to precisely match the weight, tensile strength limits, and physical footprint of specific cable types and site constraints. This prevents under- or over-speccing, optimizing efficiency and cost.

- Environmental Adaptations: Designing equipment for extreme temperatures (e.g., arctic -40°C or desert +55°C operations), highly corrosive atmospheres (e.g., offshore oil rigs, chemical plants), or hazardous zones (e.g., petrochemical facilities requiring ATEX or IECEx compliance). This might involve specialized alloys, multi-layer marine-grade coatings, sealed components, or explosion-proof electrical systems.

- Ergonomic & Operational Enhancements: Custom control interfaces, remote operation capabilities (wired or wireless up to 500m range), or specialized mounting options (e.g., skid-mounted, trailer-mounted, rail-mounted) to integrate seamlessly with existing site infrastructure or improve operator comfort and safety.

- Integration with Project-Specific Software: Developing API links for our smart equipment to integrate with client's project management, SCADA, or asset tracking systems, providing a holistic view of operations and enabling predictive maintenance.

Our deep engineering expertise allows us to provide solutions that go beyond standard offerings, ensuring optimal performance and maximum ROI for even the most demanding projects. This client-centric approach has fostered long-term partnerships and a reputation for tackling complex challenges effectively.

Figure 6: Custom-engineered cable drum handling solution, showcasing adaptability in design.

Application Case Studies: Real-World Impact

Our cable pulling tools have been successfully deployed in numerous high-profile projects worldwide, demonstrating their reliability and efficiency in diverse and challenging environments.

Case Study 1: High-Voltage Transmission Line Upgrade, North America

Challenge: Installation of 20 km of new 345kV underground transmission cable through dense urban corridors, requiring precise tension control (max 150 kN pull force) and minimal disruption. Cable sections weighed up to 15 tons per drum, often requiring installation through existing, narrow conduits.

Solution: We provided a fleet of custom-configured hydraulic cable pulling winches (150 kN capacity) with integrated data logging and automatic tension regulation, along with heavy-duty Cable Drum Roller Jacks. Our specialized cable tray rollers were strategically placed at bend points to minimize friction (friction coefficient reduced by an average of 40%) and protect the cable sheath.

Outcome: The project was completed 15% ahead of schedule, with zero instances of cable damage. Real-time data allowed for immediate adjustments, optimizing pulling parameters and reducing overall energy consumption by an estimated 18%. Client feedback noted, "The precision and reliability of their equipment significantly de-risked this critical urban infrastructure project, meeting strict municipal timelines and safety requirements."

Case Study 2: Offshore Wind Farm Inter-Array Cable Deployment, Europe

Challenge: Laying over 50 km of subsea inter-array cables for an offshore wind farm, operating in highly saline and dynamic marine environments. The cables were heavy (up to 80 kg/meter) and required continuous, stable pulling force from a moving vessel (up to 100 kN).

Solution: We engineered bespoke marine-grade cable pulling equipment, including a specialized subsea cable pulling winch with advanced corrosion protection (EN ISO 12944-C5-M certified coating) and dynamic tension compensation. Custom heavy-duty cable pulling socks were used to attach to the armored cables securely, rated for a breaking load of 150 kN.

Outcome: The system maintained a consistent pulling force within +/- 2% of target, even in fluctuating sea conditions (up to Sea State 4). This precision was crucial for preventing cable damage and ensuring correct seabed placement. The project demonstrated robust performance, even in challenging weather, leading to on-time completion and a reduction in operational risks by minimizing manual intervention and maximizing automated control.

Figure 7: A compact cable pulling winch deployed in a field application, ideal for constrained spaces.

Commitment to Trust: FAQ, Lead Times, Warranty & Support

Frequently Asked Questions (FAQ):

Q: What is the typical lead time for standard cable installation equipment?

A: For standard products, lead times generally range from 4-6 weeks, depending on inventory levels and specific configuration. Custom orders will have lead times quoted on a project-by-project basis, following detailed design approval. We aim for transparency and consistent communication throughout the order process.

Q: What warranty do you offer on your cable pulling tools?

A: We provide a comprehensive 12-month warranty covering manufacturing defects and material failures under normal operating conditions. This warranty can be extended to 24 months for qualifying products or through specific service agreements. Full warranty terms and conditions are available upon request.

Q: Can your cable pulling equipment be used in hazardous environments?

A: Yes, we offer specialized versions of our equipment designed and certified for use in hazardous environments (e.g., ATEX compliant for petrochemical industries or explosion-proof for mining). These solutions undergo stringent testing and certification processes to ensure maximum safety. Please discuss your specific requirements with our sales team for appropriate recommendations.

Q: Do you provide training for operating the cable pulling tools?

A: Absolutely. We offer comprehensive training programs, including on-site demonstrations, remote workshops, and detailed operational manuals. Our training focuses on safe operation, optimal performance techniques, and basic maintenance procedures, ensuring your team is fully competent in utilizing our equipment. Customized training modules can be developed to align with your operational protocols.

Lead Time & Fulfillment:

Our streamlined manufacturing and logistics processes are designed for efficient order fulfillment. For standard configurations, lead times typically range from 4-6 weeks. For urgent requirements or large-scale project orders, we work closely with clients to establish expedited production and delivery schedules, leveraging our global supply chain partnerships. Our commitment to on-time delivery is supported by robust project management and real-time tracking systems.

Warranty Commitments:

Every piece of cable pulling equipment is backed by a 12-month warranty from the date of purchase, covering defects in materials and workmanship. This commitment reflects our confidence in the quality and durability of our products, which are manufactured to the highest industry standards. For specific project needs, extended warranty packages and comprehensive service agreements are available, providing enhanced peace of mind and long-term asset protection.

Dedicated Customer Support:

Our commitment extends beyond the sale. We offer comprehensive after-sales support, including readily available technical assistance, a global network for spare parts availability, and preventative maintenance services. Our team of experienced engineers and support staff are available 24/7 to provide expert guidance and resolve any operational queries, ensuring your cable pulling tools perform optimally throughout their service life. Contact us via phone, email, or through our dedicated online portal for prompt and efficient assistance.

Conclusion

The continuous evolution of infrastructure demands increasingly sophisticated and reliable cable installation solutions. Specialized cable pulling equipment is not merely accessories but fundamental components that ensure the safety, efficiency, and longevity of complex cable networks across various industries. By prioritizing advanced materials, precision engineering, rigorous testing, and comprehensive after-sales support, manufacturers like us contribute significantly to the success of critical projects globally. Investing in high-quality, technically superior equipment is an investment in operational excellence and long-term reliability for your most challenging cable deployment initiatives.

References

- ISO. (2023). ISO 9001:2015 Quality management systems — Requirements. International Organization for Standardization.

- ASTM International. (2022). Annual Book of ASTM Standards, Volume 01.03 (Steel – Metallic-Coated Products). ASTM International.

- CIGRE. (2021). Technical Brochure 842: Cable Installation in Challenging Environments. International Council on Large Electric Systems.

- The Institute of Electrical and Electronics Engineers (IEEE). (2020). IEEE 525 Standard for the Design and Installation of Cable Pulling and Laying Equipment for Substation and Industrial Applications. IEEE.

- European Committee for Standardization (CEN). (2018). EN ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles. CEN.

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025