-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

Jan . 29, 2025 03:45 Back to list

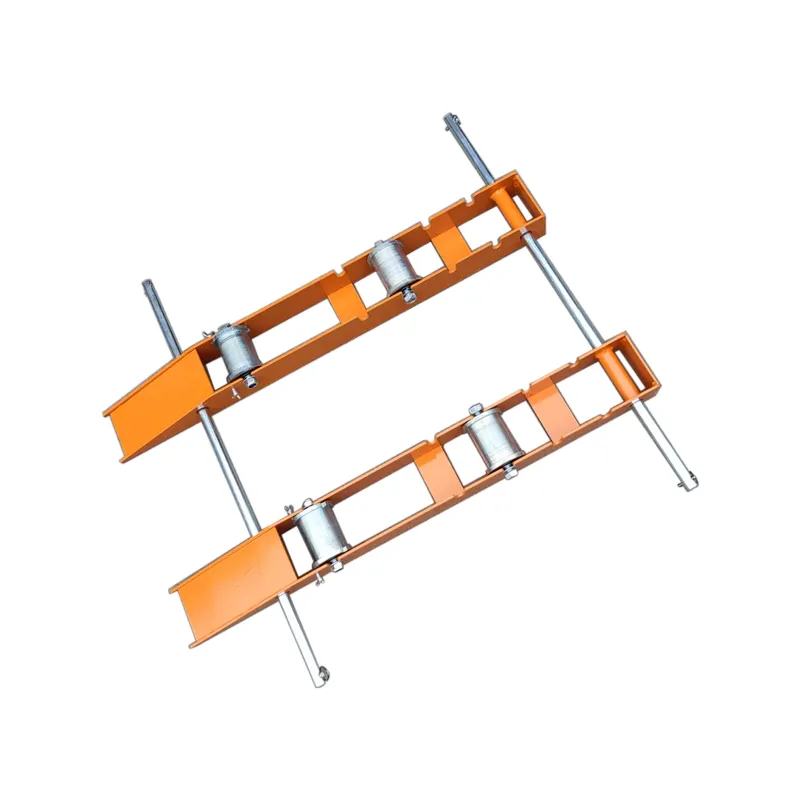

cable clamp

Wire rope tension clamps are an essential component in a myriad of industrial applications, providing vital support in ensuring the safety and efficiency of operations. These clamps are designed to secure wire ropes, which are critical in lifting, rigging, and various tension-related tasks. The importance of selecting the right wire rope tension clamp cannot be overstated, as it directly impacts the performance and longevity of your equipment.

A real-life example of the importance of using quality wire rope tension clamps can be seen in maritime applications. In shipping, the security of cargo during transit is paramount, and wire rope tension clamps play a crucial role in fastening containers and other equipment securely on deck. Inferior quality clamps can lead to disastrous outcomes, including cargo loss or severe damage, with potentially catastrophic financial and safety implications. In construction, particularly in high-rise projects, wire rope tension clamps are used extensively in elevators and hoisting systems. The failure of these clamps due to substandard materials or incorrect installation can put lives at risk and lead to significant operational disruptions. Thus, investing in certified, high-quality tension clamps not only ensures compliance with safety regulations but also protects workers and assets. It's also vital to incorporate regular maintenance checks and inspections to ensure the continued effectiveness of wire rope tension clamps. Scheduling periodic inspections, looking for signs of wear and tear, and replacing worn parts are necessary steps to maintain operational integrity and safety. In conclusion, wire rope tension clamps are a small yet indispensable part of industrial frameworks that demand careful selection based on practical insights and proven expertise. Working with reputable manufacturers, ensuring adherence to industry standards, and committing to regular maintenance are all practices that enhance their trustworthiness and effectiveness. This approach not only safeguards your operations but also optimizes them, reflecting prudent resource management and a proactive stance on safety.

A real-life example of the importance of using quality wire rope tension clamps can be seen in maritime applications. In shipping, the security of cargo during transit is paramount, and wire rope tension clamps play a crucial role in fastening containers and other equipment securely on deck. Inferior quality clamps can lead to disastrous outcomes, including cargo loss or severe damage, with potentially catastrophic financial and safety implications. In construction, particularly in high-rise projects, wire rope tension clamps are used extensively in elevators and hoisting systems. The failure of these clamps due to substandard materials or incorrect installation can put lives at risk and lead to significant operational disruptions. Thus, investing in certified, high-quality tension clamps not only ensures compliance with safety regulations but also protects workers and assets. It's also vital to incorporate regular maintenance checks and inspections to ensure the continued effectiveness of wire rope tension clamps. Scheduling periodic inspections, looking for signs of wear and tear, and replacing worn parts are necessary steps to maintain operational integrity and safety. In conclusion, wire rope tension clamps are a small yet indispensable part of industrial frameworks that demand careful selection based on practical insights and proven expertise. Working with reputable manufacturers, ensuring adherence to industry standards, and committing to regular maintenance are all practices that enhance their trustworthiness and effectiveness. This approach not only safeguards your operations but also optimizes them, reflecting prudent resource management and a proactive stance on safety.

Next:

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy