-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Dec . 05, 2024 15:12 Back to list

'welding cable rollers - measuring wheel'

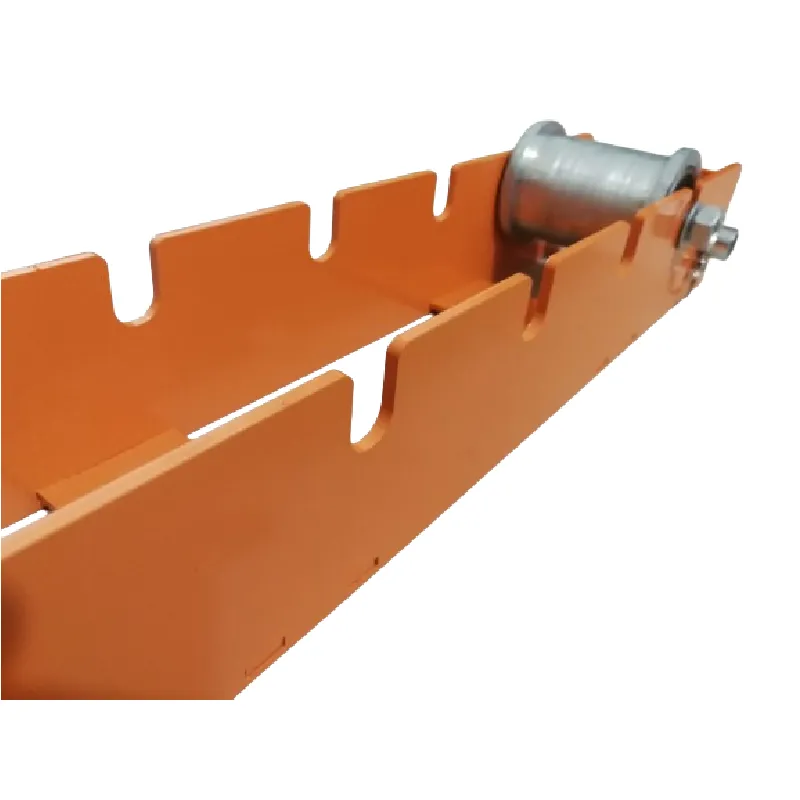

Welding Cable Rollers - Measuring Wheel An Essential Tool in the Welding Industry

In the world of welding, efficiency and precision are paramount. From construction sites to manufacturing plants, the demand for reliable welding operations never ceases. Among the many tools used to enhance welding procedures, welding cable rollers, particularly those with measuring wheels, have become essential equipment for professionals in the field. This article explores the role of welding cable rollers, their design and functionality, and how they contribute to the overall efficiency of welding projects.

Understanding Welding Cable Rollers

Welding cable rollers are specifically designed to manage and guide welding cables, ensuring they remain organized and tangle-free during operations. These rollers enable seamless movement of welding cables, reducing wear and tear and thus prolonging the lifespan of the equipment. The design of these rollers varies, but they are generally made from durable materials that can withstand the harsh conditions typically found in welding environments.

One of the noteworthy features of some welding cable rollers is the incorporation of a measuring wheel. This addition transforms a simple cable roller into a multifunctional tool that not only guides cables but also aids in precise measurement during welding tasks. The measuring wheel is often calibrated, allowing welders to take accurate measurements of distance or layout directly from the rollers themselves.

Benefits of Using Welding Cable Rollers with Measuring Wheels

1. Efficiency in Operations The primary advantage of utilizing cable rollers with measuring wheels is the significant increase in efficiency they bring to welding projects. By allowing welders to measure distances directly from the roller, time and effort are saved. This streamlined operation means that professionals can focus more on the actual welding process rather than on the logistics of handling cables and measuring distances separately.

'welding cable rollers - measuring wheel'

2. Precision In welding, precision is crucial. Any discrepancies in measurements can lead to faulty welds, requiring rework and additional costs. The measuring wheel integrated into the roller provides accurate readings that help ensure precise gaps and lengths are maintained throughout the welding process.

3. Reduced Cable Damage Welding cables are susceptible to damage if not managed properly. The rollers keep the cables off the ground and prevent them from being tripped over, reducing the chances of abrasion or cuts that can compromise their integrity. This ensures a safer working environment and minimizes the need for frequent replacements of damaged cables.

4. Versatility The versatility of cable rollers with measuring wheels makes them suitable for a wide range of applications. Whether in industrial settings, construction sites, or remote locations, these tools can adapt to various welding scenarios, making them an indispensable asset for welders everywhere.

5. Improved Safety Safety is always a priority in welding environments. Using cable rollers helps organize the work area by keeping cables in check, reducing tripping hazards. Additionally, having accurate measurements readily available decreases the risk of errors that could lead to accidents or injuries.

Conclusion

In summary, welding cable rollers equipped with measuring wheels represent a significant advancement in welding technology. They streamline operations, enhance precision, protect cables, and improve safety within the workspace. As the welding industry continues to evolve, the importance of such multifunctional tools cannot be overstated. Professionals looking to optimize their welding processes should consider investing in high-quality welding cable rollers with measuring wheels to better manage their operations and achieve superior results.

By incorporating this innovative tool into their workflows, welders can significantly improve their productivity and the quality of their work, paving the way for successful and efficient projects that meet the rigorous demands of modern industry. As we look to the future, it is clear that tools that combine functionality and efficiency will remain at the forefront of welding technology advancements.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025