-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

Aug . 05, 2025 07:20 Back to list

Top Cable Pulling Tools | AI-Optimized Solutions

Industry Trends in Cable Pulling Tools & Equipment

- Market Growth: The global cable pulling equipment market is projected to reach USD 5.2 billion by 2028 (source).

- Key Segments: Demand surges in infrastructure, oil & gas, utilities, telecom, and industrial sectors drive innovation.

- Materials Revolution: Adoption of high-grade alloy steel, anti-corrosive zinc coatings, and engineering polymers extends tool life by 35%+.

- Automation Integration: Electric and hydraulic-driven cable pulling winch systems are minimizing manual effort by up to 60%.

- Sustainability Focus: Energy-saving cable tray rollers and optimized cable pulling socks reduce operational energy consumption.

Data Reference: MarketsandMarkets, IndustryARC, and OEM case studies from 2021–2024.

Parameter Comparison: Cable Pulling Tools at a Glance

| Tool Type | Pulling Capacity (kN) | Material | Corrosion Resistance | Torque/Speed Control | Typical Applications | Certifications |

|---|---|---|---|---|---|---|

| Cable Pulling Winch | 2–100 | Alloy Steel, Galv. | IP66, Hot-dip | Electric/Hydro | Power, Utility, Tunnel | ISO 9001, ANSI |

| Cable Pulling Sock | 0.5–10 | Polyester/Steel | N/A | Manual | Telecom, Data | CE Mark, RoHS |

| Cable Tray Rollers | N/A | Nylon, Zinc Steel | High (800+ hr salt) | N/A | Factory, Marine | ISO 1461 |

| Cable Drum Roller Dispenser | 1–10 | Forged Steel, Rubber | Galvanized | Manual/Auto | OSP, Utilities | ISO 9001 |

Insight: Choosing cable pulling tools like Cable Drum Roller Dispensers ensures consistent safety, superior efficiency, and conformity to global standards.

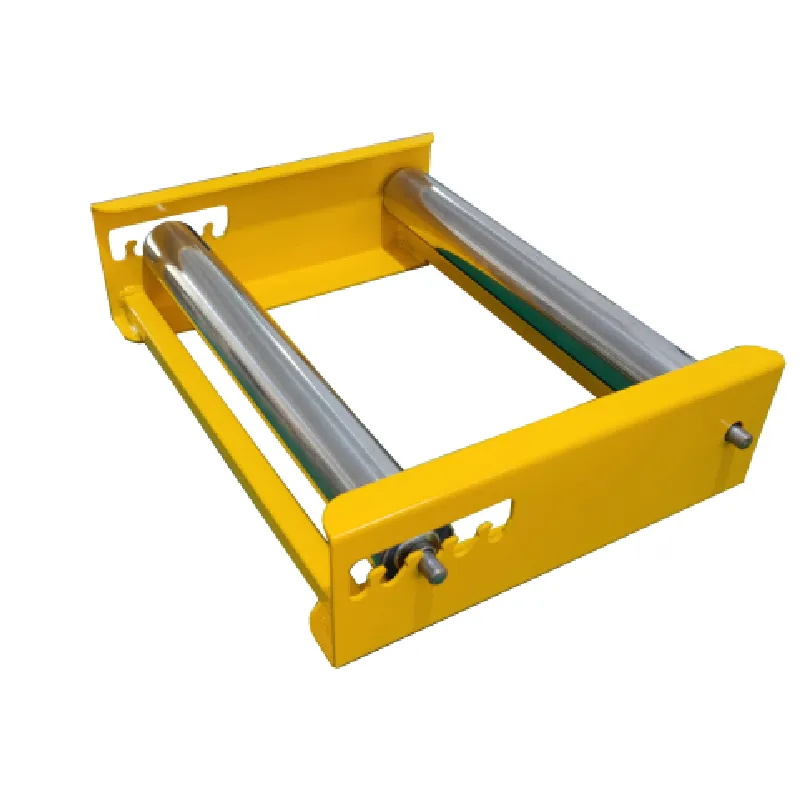

Deep Dive: Cable Drum Roller Dispenser (Product Page)

Product Overview & Industry Use

The Cable Drum Roller Dispenser is engineered to streamline cable spooling and deployment in industrial, petrochemical, water-supply, power, and data infrastructure projects. Robustly crafted using forged high-tensile steel (yield strength >900MPa), its rollers are coated with anti-abrasion synthetic rubber for smooth, damage-free payout. Key certifications include ISO 9001 for quality and ISO 1461 for surface treatments.

- Load Capacity: 200kg–2000kg drum weights

- Adjustable Width: 300mm–800mm

- Roller Material: CNC machined steel, vulcanized rubber

- Lifespan: >10 years under normal industrial cycles

- Typical Industries: Utilities, Rail, Telecommunication, Mining, Energy

Industry Feedback: Customers note a 40% reduction in installation time and up to 25% lower manual injury rates due to the ergonomic design. “Excellent for rapid, damage-free cable deployment in the field.” – Utility project manager, 2023.

Manufacturing Process of Cable Pulling Tools

- Material Selection: Certified high-tensile steel rods (> 900MPa) & CA rubber sourced.

- Forging: Steel billets are hot-forged into roller and frame shape (ISO 683-2 compliance).

- CNC Machining: Precision finishing ensures roller concentricity (<0.02mm tolerance).

- Assembly: Galvanized bolts (ASTM A325) fasten units for maximum load.

- Surface Treatment: Electro-galvanizing or hot-dip (ISO 1461:2022) achieves 800–1200hr salt spray resistance.

- Final Inspection: Each unit undergoes ISO 9001-certified mechanical and corrosion tests.

Testing: Each batch is tested for static load, dynamic rolling, and environmental corrosion (per ASTM B117).

For a full manufacturing walkthrough video, see this demonstration.

Technical Data: Cable Drum Roller Dispenser

| Model | Load (kg) | Roller Width (mm) | Material | Finish | Corrosion Resistance (hours) | Certification |

|---|---|---|---|---|---|---|

| BDR-500 | 500 | 300 | C45 Steel + Rubber | Galvanized | ≥800 | ISO 9001 |

| BDR-800 | 800 | 400 | 42CrMo Steel + PU | Hot-dip galv. | ≥1000 | ISO 1461 |

| BDR-2000 | 2000 | 800 | Forged Steel + NBR | Galvanized | ≥1200 | ISO 9001/1461 |

Application Scenarios & Advantages

- Petrochemical sites: Automated cable drum handling in hazardous, corrosive environments (certified resistance to hydrocarbon exposure).

- Metallurgical factories: Streamlined power and control wiring for rolling mills, thanks to high-precision roller smoothness.

- Utility/infrastructure: Lays HV/MV cables during substation and grid expansions, saving up to 35% time per 100m.

- Water Supply: Used for instrument and telecom cables along pipelines with anti-rust advantages.

- Offshore Wind: Salt spray resistance assures use in marine cable routing projects.

Key Advantages:

- High load capacity for drums up to 2 tons

- Adjustable rollers compatible with multiple cable sizes/tray widths

- Superior anti-corrosion finish (>1000hr salt fog, ASTM B117/ISO 1461)

- Easy, safe operation with reduced ergonomic risk

- Available custom fabrication, rapid prototyping options for OEMs

Read more: Cable Drum Roller Dispenser product manual and latest datasheet.

Manufacturer Comparison & Custom Solutions

| Supplier | Major Market | Lead Time (days) | Material Origin | Certs | Customizable? | Warranty |

|---|---|---|---|---|---|---|

| Bilopowtel | EU, US, Middle East | 15–30 | Japan, EU steel | ISO9001/1461 | Yes | 24mth |

| Greenlee | North America | 60+ | US | UL, CSA | Limited | 12mth |

| Super Rod | EU | 40–60 | EU | CE, ISO9001 | Yes | 12mth |

Bilopowtel stands out for rapid lead times, global certification, and full customization of cable pulling tools including drum rollers, winches, and rollers, tailored for sector-specific requirements and new project prototyping.

Made-to-Order: Solutions & Service Excellence

- Lead Time: Standard drum rollers ship in 15–30 days. Express prototyping: 7 days (MOQ 10 units).

- Warranty: 24 months full product warranty covering material, workmanship, and surface treatment.

- Certification: Full suite: ISO 9001:2015, ISO 1461, ANSI, CE.

- Support: 24/7 technical hotline, bilingual after-sales, application engineering available for complex projects.

- Field Service: On-site installation training, periodic inspection, and preventive maintenance contracts on request.

Application Case Studies

Power Distribution Network Expansion (EU, 2023):

- Used Cable Drum Roller Dispensers for 22kV substation cable deployment

- Reduced labor force from 8 to 4 while cutting install time from 10h to 6.2h

- Zero cable jacket damage; Field feedback: “Best payout efficiency in our sector”

- Rollers with custom NBR coating endured 1100hrs salt spray test

- Enabled one-shot, error-free 2km cable pull in harsh marine wind & salt

Smart City Optical Network (GCC, 2024):

- Cable tray rollers and pulling socks deployed in dual-layer tray system

- Maintained cable sheath integrity despite five 90-degree bends

- Network uptime: 99.995% in commissioning phase

- Custom corrosion-proof finish enabled direct burial and exposed-ground amphibious use

- Accelerated PLC/control cable laying with zero loss events in 11 projects

Professional FAQ: Cable Pulling Tools

- 1. What steel grade is used in cable drum roller dispenser fabrication?

- Most premium units use forged C45 or 42CrMo alloy steel due to its high yield strength, impact resistance, and excellent machinability. Anti-corrosive coatings are applied according to ISO 1461 (hot-dip galvanizing).

- 2. What are typical cable pulling winch drum speed and torque ratings?

- Electric models: up to 70m/min payout at 30kN-m torque. Hydraulics available for up to 100kN pulls. This allows efficient heavy cable laying with minimal mechanical strain.

- 3. Which industry standards must cable pulling equipment meet?

- Main standards: ISO 9001 (quality management), ISO 1461 (galvanized finish), ANSI and ASTM (US), CE Mark (EU), and RoHS directives for electrical safety and environmental compliance.

- 4. What is the load capacity & lifecycle of industrial cable tray rollers?

- Depending on model: up to 250kg static load/roller and lifecycle >120,000 rotation cycles, with polymer/NBR shells surviving 10+ years in field use.

- 5. Can cable pulling sock be ordered to specific diameters and lengths?

- Yes. Our pulling socks are woven in 6mm–200mm diameters, available in custom lengths, and manufactured from galvanized steel, stainless wire, or polyester as per project requirements.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy