Aug . 18, 2025 02:40 Back to list

Reliable Cable Pulling Tools & Equipment Solutions

The Crucial Role of Advanced Cable Pulling Tools in Modern Infrastructure

In the rapidly evolving landscape of global infrastructure development, the efficiency, safety, and reliability of cable installation are paramount. From extensive power grids and telecommunications networks to complex industrial facilities, the demand for robust and precise cable pulling tools has never been higher. These specialized tools are engineered to facilitate the smooth and controlled deployment of various types of cables, ranging from heavy-duty power cables and delicate fiber optics to communication lines, across diverse and often challenging terrains. The modern infrastructure projects, whether they involve underground conduits, overhead transmission lines, or in-building installations, require solutions that minimize downtime, reduce labor costs, and prevent damage to expensive cables. The industry is currently witnessing a significant trend towards automation and intelligence in cable installation, driven by the need for higher speeds and greater accuracy. This paradigm shift necessitates the adoption of technologically advanced cable pulling tools that can integrate seamlessly with digital monitoring systems, offering real-time data on critical parameters such as tension, speed, and distance, which are indispensable for successful cable deployment and adherence to project specifications. This evolution underscores the importance of selecting not just any tool, but sophisticated cable pulling tools designed for precision, durability, and a prolonged service life, capable of withstanding the rigors of demanding construction environments while ensuring maximum operational safety and efficiency.

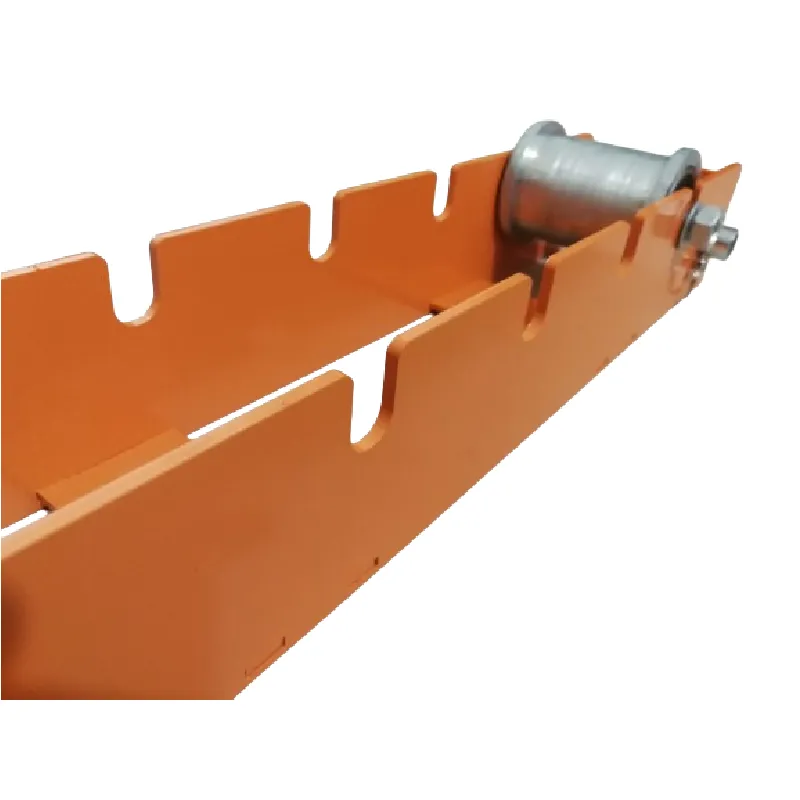

The technological advancements in cable pulling equipment are not merely incremental; they represent a fundamental rethinking of how cables are laid and managed throughout their lifecycle. For instance, the integration of smart sensors and IoT capabilities into modern cable pulling winches allows operators to monitor pulling force dynamically and predict potential issues, preventing over-tensioning that could damage cable insulation or conductors, thereby safeguarding valuable assets. Similarly, innovative cable pulling sock designs now offer superior grip and distribute pulling forces more evenly, minimizing stress concentrations on the cable jacket and ensuring a gentle yet firm hold. These devices are no longer simple mechanical components but sophisticated systems engineered to optimize every phase of the pulling operation from setup to completion. The growing complexity of infrastructure projects, such as smart cities, renewable energy farms, and high-speed rail networks, introduces new challenges that traditional methods cannot adequately address. These projects often involve installing cables over long distances, around multiple bends, or through congested areas, where the risk of snags or excessive friction is exceptionally high. Advanced cable tray rollers and specialized guides are now designed with ultra-low-friction materials and articulate designs to significantly reduce drag and protect cables during transit, extending their lifespan and ensuring unimpeded installation. Furthermore, environmental considerations are driving the demand for more sustainable manufacturing processes and longer-lasting cable pulling tools, reducing waste and the carbon footprint associated with large-scale infrastructure development. The industry's push towards greater operational efficiency also includes a focus on modular and adaptable cable pulling tools that can be easily reconfigured for different cable sizes and installation requirements, providing unparalleled versatility and economic benefits to contractors and project managers alike.

Unpacking the Manufacturing Excellence of Cable Pulling Tools

The robust performance and unwavering reliability of advanced cable pulling tools are deeply rooted in their meticulous manufacturing processes and the uncompromising quality of materials used. The journey begins with the careful selection of high-grade raw materials, typically comprising aerospace-grade aluminum alloys for lightweight yet strong components, high-tensile steel for structural elements requiring immense strength and rigidity, and specialized engineering polymers for low-friction surfaces like those found in cable tray rollers. For instance, the Cable Drum Roller Jack, a pivotal piece of cable pulling equipment, frequently utilizes hardened alloy steel for its critical load-bearing axles and a robust frame constructed from certified structural steel, ensuring both an exceptionally high load capacity and outstanding durability under continuous heavy use. The manufacturing flow typically encompasses several critical stages: initial design and simulation using advanced finite element analysis (FEA) to predict performance under stress, precise material preparation, cutting-edge fabrication, advanced surface treatment, precision assembly, and rigorous multi-stage quality assurance. Fabrication processes often include advanced techniques such as CNC (Computer Numerical Control) machining, which ensures unparalleled precision and consistency in component dimensions and surface finishes, critical for parts requiring exact tolerances and smooth operation. For structural frames, welding processes adhere to stringent international standards, such as AWS (American Welding Society) D1.1 for structural steel and ASME Boiler and Pressure Vessel Code (BPVC) Section IX for welding and brazing qualifications, guaranteeing weld integrity and superior structural strength.

Further along the manufacturing spectrum, specialized processes like forging and precision casting are employed for components requiring superior mechanical properties, such as enhanced toughness and ductility, or intricate geometries that would be difficult to machine from solid stock. Forging significantly refines the grain structure of metals, boosting their ultimate tensile strength and fatigue resistance, which is absolutely essential for parts under constant cyclical loading and dynamic stresses typical of cable pulling tools. Precision casting, on the other hand, allows for the creation of complex shapes with minimal material waste and excellent surface finish, often utilized for intricate housings or specialized pulley designs that integrate multiple functionalities. After primary fabrication, components undergo various sophisticated surface treatments, including high-performance powder coating for superior corrosion resistance and enhanced aesthetics, or galvanization for ultimate protection against severe environmental degradation, particularly crucial for cable pulling equipment exposed to harsh outdoor conditions in industries like petrochemical, marine, or wastewater treatment. Each stage is meticulously monitored and documented, strictly adhering to international quality management systems such as ISO 9001:2015, which dictates comprehensive quality control procedures from raw material inspection through to final product testing and packaging. Advanced non-destructive testing (NDT) methods like ultrasonic testing, magnetic particle inspection, and liquid penetrant testing are frequently employed to detect any internal flaws, micro-cracks, or surface imperfections that could compromise the long-term integrity and safety of the cable pulling tools. The projected service life of these meticulously engineered tools is significantly extended through these rigorous processes, often exceeding 10-15 years under typical operating conditions, offering a substantial and measurable return on investment for companies in sectors like energy transmission, telecommunications, and heavy construction.

Technical Parameters and Performance Benchmarks of Cable Pulling Solutions

Understanding the comprehensive technical parameters of cable pulling tools is absolutely crucial for selecting the right equipment for specific applications, ensuring not only optimal operational performance but also paramount safety. Key specifications typically include maximum pulling force (or capacity), applicable cable diameter range, operational speed (often variable), motor power (for motorized cable pulling winches), and detailed material composition of critical components. For example, a heavy-duty cable pulling winch designed specifically for power transmission lines might boast an impressive maximum pulling force of 10 tons (approximately 22,000 lbs) with finely adjustable speeds ranging from a precise 0.5 meters per minute for delicate initial pulls to a rapid 15 meters per minute for long, clear runs, typically powered by a high-efficiency 50 kW hydraulic or electric motor. Its large drum capacity would be engineered to accommodate hundreds of meters of high-strength steel wire rope, making it eminently suitable for extensive, long-distance pulls. In stark contrast, a lighter-duty winch intended for delicate telecommunications cables might possess a more controlled pulling force of 2 tons and even finer speed control, specifically designed to prevent any form of damage to sensitive fiber optic strands which are highly susceptible to micro-bending losses. The precise design of cable tray rollers is equally critical, with parameters such as roller diameter, individual load capacity per roller, and the specific material of the roller surface (e.g., durable nylon, lightweight aluminum, or advanced polymer composite) directly impacting their overall effectiveness in reducing friction and providing superior protection to the cable jackets during transit. Polymer composite rollers, for instance, offer excellent chemical resistance and non-abrasive contact properties, making them ideally suited for sensitive cables or deployment in highly corrosive industrial environments.

The table below provides a comprehensive comparative overview of typical technical parameters for various types of cable pulling equipment components, meticulously highlighting the broad range of capabilities and specialized designs available in the contemporary market. This data is meticulously compiled from prevailing industry standards, engineering specifications, and common product offerings from leading manufacturers, showcasing the remarkable diversity and advanced specialization within this critical field. Important engineering terms to consider include tensile strength, which refers to the maximum stress a material can withstand while being stretched or pulled before permanent deformation or breaking occurs—a vital metric for evaluating the integrity of components like cable pulling sock materials or the winch cables themselves. Load rating precisely indicates the maximum weight or force a piece of equipment can safely and reliably bear without risk of failure, crucial for ensuring operational safety. Fatigue resistance measures a material's inherent ability to resist structural failure or fracture under conditions of repeated or cyclical stress applications, which is paramount for the long-term durability and reliability of all cable pulling tools that endure continuous operational cycles. These stringent performance benchmarks ensure that products not only meet but often exceed demanding operational requirements, thereby contributing significantly to both project efficiency and the overall safety of personnel on site. The sophisticated integration of advanced sensors and intelligent control systems now allows for real-time monitoring of these critical parameters during operation, providing instantaneous feedback to operators and enabling proactive adjustments to prevent issues like dangerous over-tensioning or sudden snagging. This unprecedented level of data-driven insight is fundamentally transforming cable installation from a labor-intensive operation into a precise, highly engineered discipline, effectively minimizing human error and significantly enhancing overall project success rates, ultimately delivering superior outcomes for complex infrastructure initiatives.

| Equipment Type | Key Parameter | Typical Range/Value | Material/Feature Highlight |

|---|---|---|---|

| Cable Pulling Winch | Max Pulling Force | 1 - 15 tons (2,200 - 33,000 lbs) | Hydraulic/Electric Drive, Smart Tension Control, Variable Speed |

| Cable Drum Roller Jack | Load Capacity | 5 - 20 tons per pair (11,000 - 44,000 lbs) | High-tensile Steel Frame, Adjustable Height, Corrosion-Resistant Finish |

| Cable Tray Rollers | Roller Material & Capacity | Nylon, Aluminum, Polymer Composite; 1-5 kN per roller | Ultra-Low Friction, Anti-corrosive, Self-aligning options, Robust Bearings |

| Cable Pulling Sock | Breaking Strength | 0.5 - 50 tons (1,100 - 110,000 lbs) | Galvanized Steel, Stainless Steel, High-Ductility Material, Single/Double Weave |

| Underground Cable Feeder | Feeding Speed & Force | 5 - 30 m/min; 1-3 kN assist force | Modular Design, Variable Speed Control, High-Traction Belts, Remote Operation |

Versatile Application Scenarios and Distinct Technical Advantages

The diverse and specialized range of cable pulling tools finds indispensable applications across a multitude of industries, each presenting unique and often demanding challenges that these advanced equipment pieces are meticulously designed to overcome with exceptional precision. In the critical energy sector, spanning from the construction of brand-new power substations to the essential maintenance of extensive existing transmission lines, heavy-duty cable pulling winches and exceptionally robust cable drum roller jacks are absolutely essential for the efficient and safe deployment of high-voltage power cables, which can be immensely heavy, rigid, and require careful handling. Similarly, the rapidly expanding telecommunications industry relies heavily on precise and gentle cable pulling equipment to install sensitive fiber optic cables without inducing micro-bending or other forms of damage, often utilizing smaller, highly controlled winches and specialized cable pulling socks that are engineered to distribute pulling tension uniformly across the cable jacket, protecting its delicate internal structure. The petrochemical industry, characterized by inherently hazardous environments and stringent safety standards, consistently demands corrosion-resistant and often explosion-proof cable pulling tools for the installation of instrumentation and control cabling within complex refineries, processing plants, and offshore platforms. In contemporary urban infrastructure projects, such as cutting-edge smart city developments or intricate underground utility installations, compact and highly versatile cable pulling tools are specifically preferred to navigate confined spaces and minimize disruption to surrounding areas, ensuring project completion with minimal impact on daily life. Furthermore, the mining sector employs exceptionally rugged cable pulling equipment designed to manage power and communication lines in harsh, abrasive, and often remote underground conditions, where durability and reliability are paramount. The inherent adaptability and modularity of modern cable pulling tools ensure seamless integration into these varied and challenging operational landscapes, providing solutions that are not only highly efficient but also strictly comply with stringent industry-specific regulations and safety protocols, thereby significantly enhancing overall project viability, safety, and long-term operational resilience.

Beyond their broad and versatile applicability, the distinct technical advantages of contemporary cable pulling tools represent a key differentiator in the marketplace, offering substantial benefits to operators and project managers. A primary and profoundly impactful benefit is the significant enhancement in operational efficiency. By profoundly streamlining the entire cable installation process, these sophisticated tools drastically reduce the time and intensive labor required, leading to substantial and measurable cost savings over the entire project lifecycle. For instance, a single powerful and automated cable pulling winch equipped with intelligent controls can effectively replace numerous manual laborers, completing a complex pull in a matter of hours that would otherwise take multiple days using traditional methods. Secondly, these tools provide unparalleled cable protection. The precision control offered by advanced systems, coupled with meticulously engineered low-friction components like optimized cable tray rollers and specialized cable guides, minimizes the inherent risk of damage to often expensive and sensitive cables, thereby preventing costly re-installations, repairs, and project delays. Thirdly, safety on the job site is profoundly improved. Automated tension control systems prevent dangerous overloads and snap-backs, while robust designs and ergonomic features reduce manual strain and significantly lower the likelihood of workplace injuries. This is particularly vital in high-risk environments like those found in the metallurgical industry or complex water treatment sectors, where extremely heavy cables and challenging environmental conditions prevail, demanding the utmost in safety and reliability from cable pulling tools. Moreover, modern cable pulling equipment offers superior durability and an exceptionally longer service life due to the strategic use of high-strength, corrosion-resistant materials and advanced manufacturing techniques, such as meticulous CNC machining and expert robotic welding, ensuring a prolonged operational lifespan even in the most harsh and demanding operating conditions, thereby reducing maintenance costs, minimizing downtime, and increasing the overall return on investment for businesses committed to long-term infrastructure excellence.

Manufacturer Comparison and Tailored Solutions

When making strategic procurement decisions regarding cable pulling tools, discerning buyers in the B2B sector often engage in a thorough and systematic comparison of various manufacturers, assessing not just the raw product specifications but also their long-standing reputation, capacity for continuous innovation, and the robustness of their after-sales support infrastructure. Leading manufacturers consistently differentiate themselves through their unwavering commitment to research and development (R&D), continually introducing groundbreaking new technologies like IoT-enabled remote monitoring for advanced cable pulling winches or developing novel composite materials for cable tray rollers that offer superior wear resistance, reduced friction, and exceptional chemical inertness, thereby enhancing performance in challenging environments. For example, some specialized manufacturers may focus exclusively on developing ultra-high capacity equipment tailored for national grid-level power projects, while others might concentrate on producing compact, highly modular systems specifically designed for efficient urban fiber optic deployment, where space is at a premium. A critical and non-negotiable aspect of this manufacturer comparison is their strict adherence to international quality standards and industry-specific certifications, such as ISO 9001 for comprehensive quality management systems, ISO 14001 for environmental management, and various product safety certifications relevant to the target market (e.g., CE marking for stringent European markets, ANSI standards for robust North American applications, or specific IEC standards for electrical compatibility). Companies like Bilopowtel distinguish themselves by providing a comprehensive range of high-performance solutions, including the incredibly versatile Cable Drum Roller Jack, which is specifically engineered to support and facilitate the precise unwinding of even the heaviest cable drums with maximum stability and minimal friction, a vital capability for preventing costly cable damage during the critical installation phase. The hard-earned reputation of a manufacturer, often meticulously built over decades of dedicated service, their proven track record in executing large-scale, complex projects, and a consistent stream of positive customer testimonials, are invaluable indicators of long-term reliability and performance consistency, making the due diligence process absolutely essential for achieving sustained operational success.

Recognizing that generic, off-the-shelf solutions may not always optimally meet the highly unique and exacting demands of every single project, leading suppliers of cable pulling equipment are increasingly offering highly specialized and extensively customized solutions. This can involve a wide array of modifications, such as adapting standard cable pulling tools to precisely accommodate unusually large cable diameters, designing bespoke cable pulling socks specifically engineered for unique cable jacket materials or complex pulling profiles, or developing fully integrated systems that seamlessly combine pulling, feeding, and real-time monitoring functions for highly specific and challenging site conditions. For instance, a complex infrastructure project requiring the installation of multi-core cables through an intricate, multi-bend underground conduit system might necessitate custom-designed cable tray rollers featuring advanced articulating joints and specialized automatic lubrication systems to significantly minimize friction, eliminate snags, and ensure a smooth, damage-free pull over extended distances. Similarly, for critical deep-sea cable laying operations for telecommunications or power transmission, custom-built cable pulling winches with ultra-precise tensioning capabilities and robust marine-grade components are absolutely indispensable for safe and accurate deployment in demanding underwater environments. The inherent ability to provide such meticulously tailored solutions profoundly demonstrates a manufacturer's deep technical expertise, extensive engineering capabilities, and unwavering commitment to absolute customer success. This often necessitates close and collaborative engagement between the client's experienced engineering team and the manufacturer's dedicated R&D department, ensuring that the final product precisely aligns with all operational requirements, environmental constraints, and stringent safety protocols of the specific application. This bespoke approach to cable pulling tools not only maximizes operational efficiency and enhances safety but also delivers significant long-term value by optimizing performance for highly specialized, mission-critical installations, further solidifying trust in the manufacturer's proven capabilities and dedicated partnership approach.

Real-World Application Cases and Proven Performance

The true and most compelling testament to the real-world efficacy and superior performance of advanced cable pulling tools lies unequivocally in their successful deployment across diverse and challenging scenarios, where they consistently deliver on promises of unparalleled efficiency, paramount safety, and unwavering reliability. Consider, for instance, a recent major power utility project undertaken in a densely populated urban environment, where new underground power lines carrying critical electrical supply needed to be installed with absolute minimal disruption to both heavy vehicular traffic and existing underground utilities. Utilizing a meticulously selected combination of an intelligent cable pulling winch equipped with state-of-the-art automated tension control systems and a series of heavy-duty, robust cable tray rollers designed for high load capacities, the project team successfully pulled 1.5 kilometers of high-voltage 132kV cable through highly congested and complex underground conduits within a remarkably short and predetermined timeframe. The smart winch's precise controls prevented any dangerous over-tensioning, thereby safeguarding the high-value cable from damage, while the meticulously designed rollers minimized friction around multiple complex bends, significantly reducing the overall pulling force required and extending the equipment's lifespan. Another highly compelling case involves a large-scale renewable energy project, specifically the complex installation of massive submarine cables for a nascent offshore wind farm. Here, highly specialized marine-grade cable pulling equipment, including ultra-high-capacity winches and bespoke cable pulling socks meticulously designed for the unique and demanding requirements of subsea operations, played an absolutely crucial role in the successful project execution. The unparalleled precision control offered by these specialized cable pulling tools was vital in accurately maneuvering the massive cables into their precise desired positions on the seabed, demonstrating their exceptional capacity to handle extreme environmental conditions and critical infrastructure with unmatched precision and robust reliability, ultimately leading to the successful completion of the entire project ahead of its projected schedule and within budget, exemplifying the transformative power of advanced cable installation technology.

Furthermore, in the rapidly expanding telecommunications sector, the aggressive rollout of next-generation 5G networks and high-speed broadband frequently involves the extensive and intricate deployment of delicate fiber optic cables through both existing duct banks and newly constructed underground pathways. A recent project undertaken in a sprawling suburban area brilliantly showcased the remarkable efficiency and adaptability of compact, yet immensely powerful cable pulling tools. A dedicated team successfully deployed a lightweight, highly portable cable pulling winch along with a series of flexible cable tray rollers specifically designed for navigating small conduit diameters and sharp turns. This meticulously chosen setup allowed for the remarkably rapid and safe installation of several kilometers of critical fiber optic cable, effortlessly navigating numerous sharp turns and varying underground elevations with remarkable ease, thereby minimizing both labor costs and, crucially, preventing any form of damage to the ultra-sensitive optical fibers, which is often a paramount concern in high-speed data transmission infrastructure where signal integrity is non-negotiable. Post-installation operational reports consistently highlighted a dramatic reduction in installation time by over 30% compared to traditional, less advanced methods, and a near-zero incidence of any cable damage or performance degradation, directly translating into substantial and measurable cost savings for the telecom provider and ensuring the longevity of the network. These compelling real-world case studies profoundly underscore the tangible, quantifiable benefits that advanced cable pulling equipment brings to diverse and demanding industrial applications. They powerfully exemplify how the right combination of technologically superior cable pulling tools, when deployed strategically and managed expertly, can unequivocally overcome complex logistical challenges, significantly improve safety compliance, and dramatically accelerate project timelines, ultimately driving substantial economic value and establishing undeniable operational superiority for businesses operating in critical infrastructure sectors, solidifying their competitive advantage.

Ensuring Trust: FAQ, Delivery, and Warranty Commitments

Building unwavering trust with our esteemed B2B clients extends far beyond merely offering superior product quality; it encompasses providing comprehensive support, ensuring transparent processes, and backing our offerings with robust guarantees and commitments. This section aims to address the most common inquiries and clearly outlines our unwavering commitment to absolute customer satisfaction for all our advanced cable pulling tools. We understand unequivocally that reliability, predictability, and profound peace of mind are paramount considerations for industrial purchasers who are making significant investments in their operational infrastructure. Our comprehensive Frequently Asked Questions (FAQ) section is meticulously designed to provide swift and precise answers to common queries regarding product selection, optimal operational procedures, and essential routine maintenance best practices. For instance, a common and pertinent question often pertains to the projected lifespan of our cable pulling equipment; typically, with proper adherence to recommended maintenance schedules and strict adherence to operational guidelines, our high-grade steel and aerospace-grade aluminum products are engineered with exceptional durability and designed to reliably last for 10-15 years or even longer, thanks to our superior manufacturing processes like precision CNC machining, robust welding, and advanced corrosion protection treatments. Another frequent inquiry concerns product compatibility; our cable pulling tools are meticulously designed with modularity and interoperability in mind, allowing for broad compatibility with a vast array of cable types and sizes, and our highly experienced technical support team is always readily available for specific compatibility assessments and tailored recommendations for unique project requirements. We also rigorously address queries regarding specific industry standards (e.g., ISO, ANSI compliance, CE marking where applicable) and provide clear documentation on how our products consistently meet or even exceed these benchmarks, ensuring that every single piece of cable pulling equipment stands up to the most rigorous professional demands, which is absolutely critical for managing complex and high-stakes infrastructure projects, making it abundantly clear that we prioritize both peak performance and unwavering adherence to international quality and safety regulations, safeguarding your investment and operational continuity.

Transparency in logistics, alongside consistently strong and responsive after-sales support, are integral pillars of our trustworthiness and commitment to our clients. We provide clear, comprehensive, and upfront delivery cycle information, typically ranging from a swift 2-4 weeks for our standard, readily available cable pulling tools and up to 8-12 weeks for highly specialized and extensively customized cable pulling equipment, depending on the inherent complexity of the design and our current production schedule; this detailed scheduling empowers our clients to plan their critical projects with utmost effectiveness, thereby minimizing unforeseen delays and ensuring project milestones are met. All our meticulously engineered products, including the versatile Cable Drum Roller Jack and the robust cable pulling winches, come with a comprehensive and industry-leading warranty that rigorously covers manufacturing defects for a specified period, typically 12-24 months from the precise date of purchase. This generous warranty unequivocally underscores our profound confidence in the superior quality, exceptional durability, and unwavering reliability of our cable pulling tools, providing you with invaluable peace of mind. Beyond the initial warranty period, our dedicated and highly responsive customer support team provides ongoing technical assistance, ensures prompt spare parts availability, and offers expert maintenance guidance, thereby guaranteeing the long-term operational efficiency and extended lifespan of your significant investment. We offer both swift remote troubleshooting and, where absolutely necessary, on-site support to swiftly address any operational challenges or complex technical queries that may arise, ensuring minimal downtime and maximum productivity. This holistic and client-centric approach to client engagement, extending seamlessly from the initial inquiry through the entire post-purchase support phase, unequivocally reinforces our steadfast commitment to being a truly reliable and indispensable partner in your critical infrastructure development projects, fostering enduring relationships built on profound trust, uncompromising quality, and an unwavering dedication to achieving absolute customer success and unparalleled operational excellence in every endeavor.

Concluding Remarks and Expert References

The landscape of global infrastructure development is continuously evolving at an unprecedented pace, demanding increasingly sophisticated, efficient, and supremely reliable cable pulling tools. As we have comprehensively explored throughout this detailed analysis, the strategic integration of advanced manufacturing processes, rigorous multi-stage quality control measures, and innovative design principles is absolutely essential in ensuring that modern cable pulling equipment consistently meets and often exceeds the most rigorous and exacting demands of diverse and critical sectors, ranging from intricate telecommunications networks to heavy industrial installations. The unwavering emphasis on technical precision, comprehensive and integrated safety features, and the judicious selection of robust, high-performance materials directly contributes to profoundly enhanced operational efficiency, significantly reduced project timelines, and tangible, measurable cost savings over the equipment's remarkably long service life, yielding a substantial return on investment. Moreover, the proven ability of leading manufacturers to provide highly customized and bespoke solutions means that even the most unique, complex, or exceptionally challenging cable installation scenarios can be effectively addressed with meticulously tailored cable pulling tools, perfectly aligning with highly specific project requirements and environmental constraints. These collective advancements unequivocally underscore the pivotal and indispensable role that high-quality cable pulling tools play in the successful and efficient execution of critical infrastructure projects worldwide, enabling the seamless expansion, reliable maintenance, and continuous modernization of vital networks that power, connect, and sustain our modern societies, ensuring that the foundational elements of future developments remain robust, resilient, and highly efficient, thereby supporting continuous growth and innovation across all essential industrial applications and sectors.

References

- International Organization for Standardization (ISO). (2015). ISO 9001: Quality management systems – Requirements.

- American National Standards Institute (ANSI). (Various Standards, e.g., ANSI Z535.6). Product Safety Information in Product Manuals, Instructions, and Other Collateral Materials.

- Institute of Electrical and Electronics Engineers (IEEE). (Various Publications). IEEE Transactions on Power Delivery.

- Journal of Civil Engineering and Construction. (Various Articles, e.g., "Advanced Methodologies in Underground Cable Installation").

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025