-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Nov . 28, 2024 01:00 Back to list

Cable Pulling Solutions with Efficient Pulley Systems for Optimal Performance

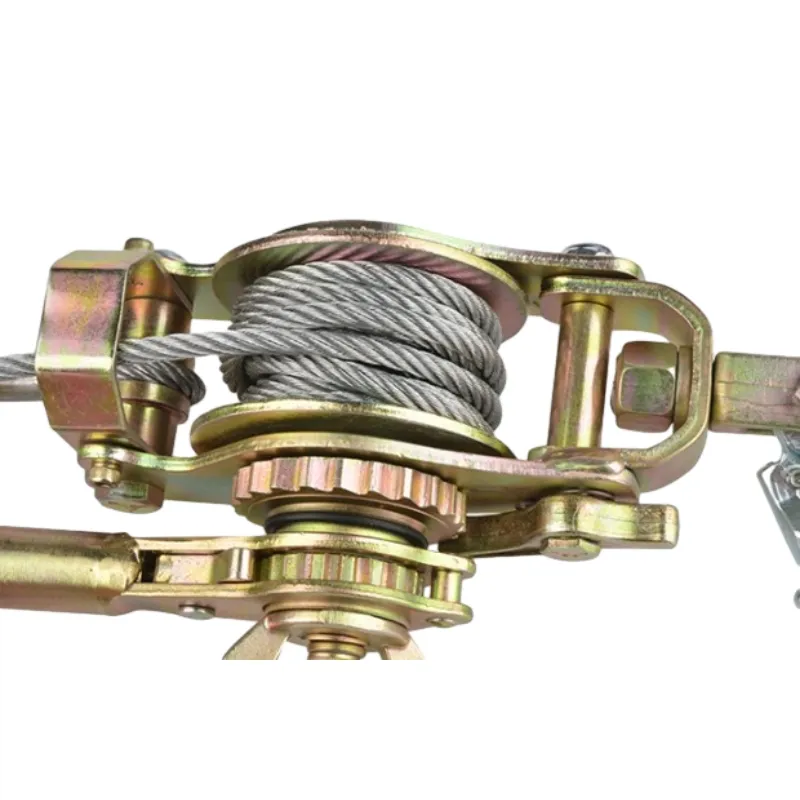

Pulleys for Cable Pulling The Essentials of Efficient Mechanical Systems

Pulleys have long been an integral part of mechanical systems, serving various purposes from lifting heavy loads to facilitating cable pulling. When it comes to cable pulling, the right pulley system can make the difference between a difficult, labor-intensive task and a smooth, efficient process. Understanding the function, design, and application of pulleys can vastly improve your experience with cable management, whether for construction, telecommunications, or other industries.

What is a Pulley?

A pulley is a simple machine that consists of a wheel on an axle or shaft designed to support movement and change of direction of a cable or belt. It can be used to lift loads or to transmit power, depending on the configuration. When we talk about pulleys for cable pulling, we are generally referring to systems designed specifically to navigate and manage cables, making the task of pulling them through conduits, ducts, or other pathways much easier.

Types of Pulleys for Cable Pulling

1. Fixed Pulleys These pulleys have a wheel that is anchored to a fixed location. They change the direction of the force applied but do not reduce the amount of force needed. Fixed pulleys are ideal for situations where the pulling force needs to be redirected, like when pulling cables around a corner.

2. Movable Pulleys In contrast to fixed pulleys, movable pulleys are attached to the load and can move in response to the applied force. They effectively reduce the effort required to lift an object or pull a cable. In cable pulling operations, they are frequently used to assist in pulling heavy or long cables.

3. Compound Pulleys A combination of fixed and movable pulleys, compound pulleys provide an advantageous mechanical advantage. This configuration allows for greater loads to be moved with less effort, making them ideal for heavy-duty cable pulling tasks.

pulley for cable pulling

4. Sheave Pulleys Specifically designed to accommodate various types of cables, sheave pulleys are commonly used in cable pulling applications. The groove in the wheel helps retain the cable, ensuring a secure grip while minimizing wear.

Applications of Pulleys in Cable Pulling

Using pulleys for cable pulling is prevalent in various industries, including telecommunications, construction, and manufacturing. As cables become increasingly important for communication and power transmission, efficient installation processes are crucial. Pulleys can assist in pulling cables through underground conduits, across rafters, or through walls, reducing the risk of cable damage and making the process more efficient.

In construction, for example, pulleys are used to manage the installation of electrical wiring or data cables in buildings. They allow workers to pull long lengths of cables with relative ease and control, ensuring that they can navigate around obstacles without causing damage. In telecommunications, where fiber optic cables are often sensitive to bending and tension, pulleys help minimize stress on the cables during installation.

Choosing the Right Pulley System

The choice of pulley system for cable pulling can depend on various factors, including the weight and type of the cable, the length of the run, and the overall installation environment. It’s crucial to assess whether a fixed or movable pulley is appropriate for the task at hand. Additionally, factors such as the diameter of the pulley, the material it is made from, and the pulley’s load rating should also be taken into consideration to ensure safety and efficiency.

Conclusion

Pulleys are an indispensable tool in the realm of cable pulling, simplifying the process and enhancing efficiency. By understanding the different types of pulleys and their respective applications, professionals across various industries can significantly improve their workflow when managing cables. Whether for telecommunications, construction, or any other field requiring cable installation, employing the right pulley system can lead to a more effective and safer operation. Investing in quality pulleys tailored to specific tasks will save time and resources, ultimately contributing to the success of the project at hand.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025