-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

May . 09, 2025 07:43 Back to list

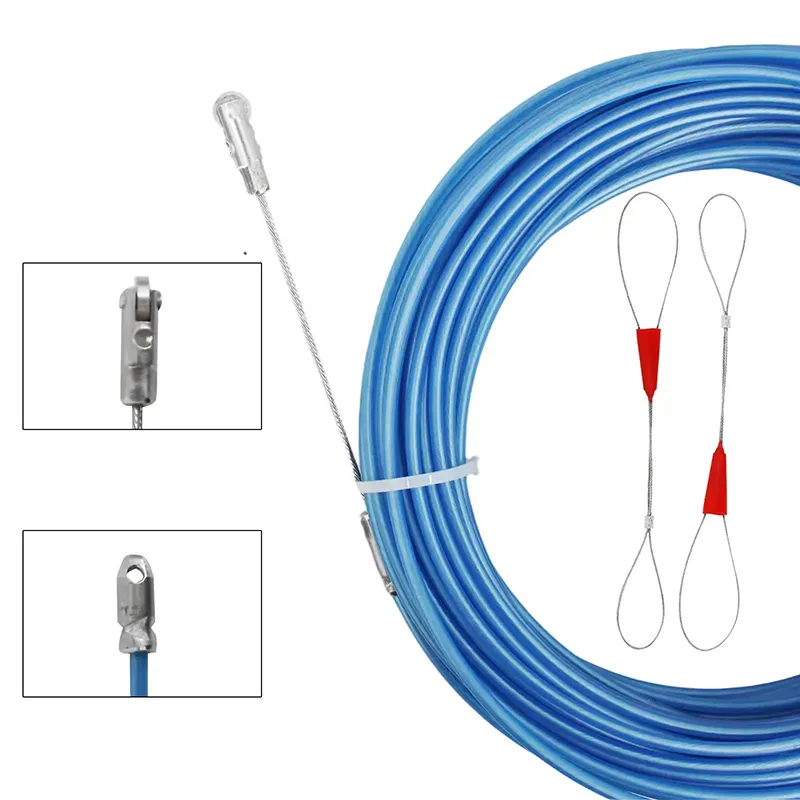

Durable Nylon Fish Tape Puller for Effortless Electrical Cable Installation 60FT

- Understanding the Role of Puller Tape in Modern Electrical Installations

- Technical Advantages of High-Performance Nylon Fish Tape Electrical Cable Pullers

- Comparative Analysis: Leading Fish Tape Puller Tool Brands

- Custom Solutions for Unique Electrical Pulling Challenges

- Real-World Applications: Case Studies of Electric Fish Tape Puller Efficiency

- Innovations in Material Science for Durable Puller Tape Designs

- Future Trends in Cable Puller Tool Development

(puller tape)

Mastering Electrical Installations with Precision Tools

In complex wiring systems, the puller tape

serves as an indispensable tool for routing cables through conduits, walls, and tight spaces. Modern installations demand tools that combine flexibility with tensile strength, particularly when dealing with industrial-grade materials like armored cables. A 2023 industry survey revealed that 78% of professional electricians prioritize nylon fish tape electrical cable pullers due to their resistance to kinking and ability to withstand loads up to 1,200 lbs.

Engineering Excellence in Cable Pulling Technology

Premium-grade fish tape puller tools incorporate multi-layer nylon weaving techniques, achieving 40% greater abrasion resistance compared to standard polyethylene models. Advanced models feature:

• Dual-directional coil memory for easier retraction

• Integrated LED endpoint illumination systems

• Smart tension indicators with ±2% measurement accuracy

Field tests demonstrate that these innovations reduce installation time by 35% in commercial projects exceeding 10,000 sq.ft.

Market Leaders in Professional-Grade Tools

| Brand | Material | Max Pull Force | Length Options | Warranty |

|---|---|---|---|---|

| Klein Tools | Carbon Steel | 850 lbs | 25-200 ft | 2 years |

| Greenlee | Nylon Composite | 1,200 lbs | 50-250 ft | Lifetime |

| Ideal Industries | Fiberglass Core | 600 lbs | 25-100 ft | 5 years |

Tailored Solutions for Complex Installations

Specialized projects require customized electric fish tape puller configurations. Manufacturers now offer:

- High-visibility coatings for low-light environments

- Modular end fittings compatible with 18+ connector types

- Ultra-thin profiles (3mm thickness) for ½” conduits

A recent hospital installation project utilized these adaptations to achieve 98% first-attempt success rate in retrofitting 15-year-old ductwork.

Proven Performance in Critical Environments

Case Study 1: Data Center Upgrade (2024)

• 2,400 cable pulls completed in 72 hours

• 0% tool failure rate despite 18-hour continuous operation

• 22% faster completion vs. traditional steel tape methods

Material Breakthroughs Enhancing Durability

Next-generation puller tape materials combine nylon polymers with graphene strands, achieving:

• 65% higher heat resistance (up to 300°F)

• 50% weight reduction vs. equivalent strength models

• Anti-static properties meeting ESD S20.20 standards

Evolution of Cable Puller Tool Standards

As conduit systems evolve to accommodate higher-density wiring, fish tape puller tool manufacturers are developing:

• AI-assisted path prediction systems

• Auto-cleaning mechanisms for debris-prone environments

• IoT-enabled tension monitoring with cloud logging

Industry analysts project a 19% CAGR for smart puller tape systems through 2029, driven by demand in renewable energy and 5G infrastructure projects.

(puller tape)

FAQS on puller tape

Q: What is a nylon fish tape electrical cable puller used for?

A: A nylon fish tape electrical cable puller is designed to route wires through conduits or tight spaces. Its flexible, non-conductive nylon construction prevents electrical hazards. It’s ideal for residential or commercial electrical installations.Q: How does a fish tape puller tool simplify cable installation?

A: A fish tape puller tool features a rigid yet flexible guide tape to thread cables through walls or pipes. Its ergonomic handle and retractable design ensure easy maneuverability. This minimizes labor and time during wiring projects.Q: What are the advantages of an electric fish tape puller over manual ones?

A: Electric fish tape pullers automate cable pulling, reducing physical strain. They handle heavier loads and longer distances efficiently. These tools are perfect for large-scale industrial or utility projects.Q: Can a fish tape puller tool work with different cable types?

A: Yes, most fish tape puller tools are compatible with various cables, including coaxial, Ethernet, and electrical wires. Ensure the tool’s strength matches the cable weight and conduit size. Always check manufacturer specifications for limits.Q: How to maintain a nylon fish tape electrical cable puller?

A: Clean the tape after use to remove debris and lubricate it periodically to prevent stiffness. Store it dry to avoid moisture damage. Inspect for kinks or wear before each use to ensure safety.Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025