-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Aug . 01, 2025 07:00 Back to list

Premium Cable Tray Pulley - Fast Install Solution

Industry Trends Surrounding Cable Tray Pulley

As global infrastructure accelerates, the demand for Cable Tray Pulley solutions has surged across sectors such as petrochemical, metallurgy, power distribution, and municipal engineering. According to MarketsandMarkets Report, the cable tray market is projected to reach USD 12.5 billion by 2027, at a CAGR of 8.1%. This growth is propelled by increasing investments in industrial automation, urbanization, and safety standards.

Cable Tray Pulley adoption is further driven by requirements for efficient cable laying, lower maintenance, energy savings and compliance to international quality standards like ISO 9001 and ANSI C135.1.

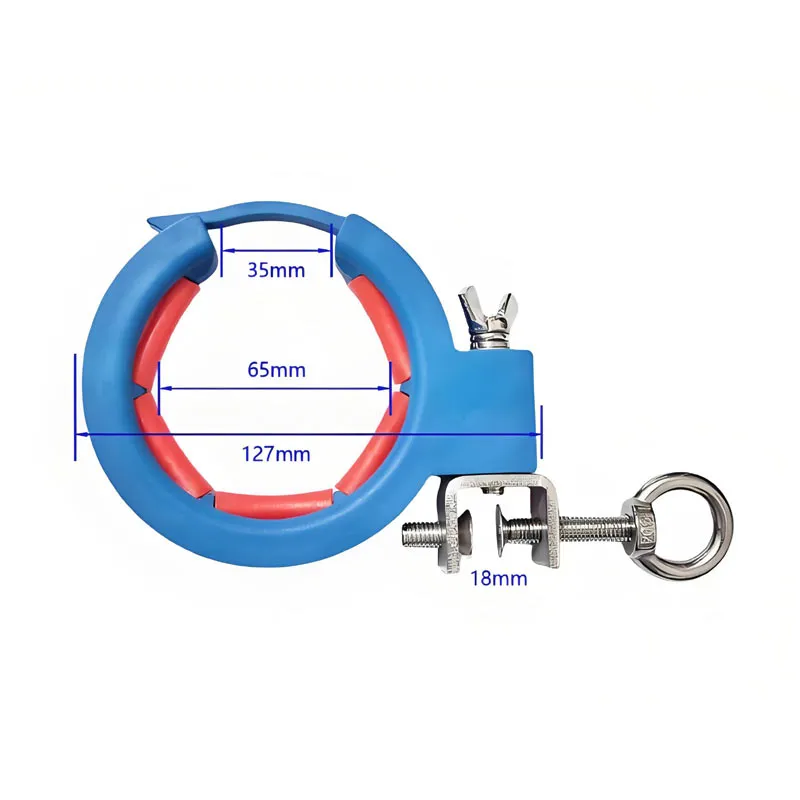

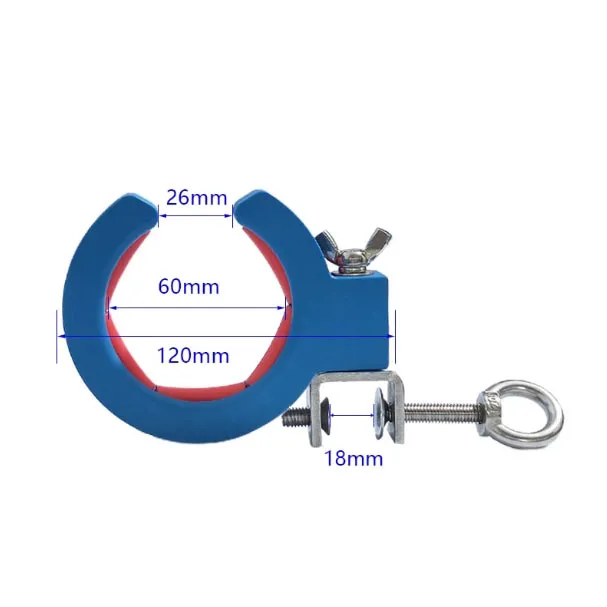

Cable Tray Pulley Key Specifications Table

| Model | Pulley Diameter (mm) | Material | Rated Load (kg) | Weight (kg) | Corrosion Protection | Standards Compliance |

|---|---|---|---|---|---|---|

| CTP-200A | 200 | ADC12 Aluminum Alloy | 160 | 5.8 | Epoxy Powder Coated | ISO 9001, ANSI C135.1 |

| CTP-250C | 250 | Q235B Carbon Steel | 220 | 8.1 | Hot-dip Galvanized | CE, ASTM A123 |

| CTP-300S | 300 | 304 Stainless Steel | 360 | 9.6 | Corrosion-resistant Polishing | ISO 1461, ROHS |

| CTP-350P | 350 | Nylon Composite | 120 | 3.2 | UV Stabilized | FDA, ISO 9001 |

Manufacturing Process Flow for Cable Tray Pulley

(Q235B Steel, Aluminum, SS304, Nylon) → Casting / Forging

(High Pressure Die Casting / Drop Forging) → CNC Machining

(Precision Grooving, Drilling)

(Hot-dip Galvanizing, Powder Coating, Polishing) → Assembly & Quality Inspection

(ISO/ANSI Load Test, Smoothness, Visual Check) → Packaging & Logistics

- Material: Selection between ADC12 Aluminum Alloy, Q235B Carbon Steel, 304 Stainless Steel, and high-performance engineering nylon ensures optimal strength-to-weight and corrosion resistance for various cable environments.

- Manufacturing Processes: Advanced high-pressure die casting for aluminum, drop forging for steel, and CNC precision machining achieve tight geometric tolerances (<0.05mm) for low-wear cable running.

- Surface treatments like Hot-dip Galvanizing or Epoxy Powder Coating deliver tested corrosion resistance over 720h salt-spray cycles (ASTM B117 standard).

- Detection & Quality: 100% products pass static load test, rotation test (0.1N friction), and compliance check with ISO 9001 and ANSI standards.

- Typical Lifecycle: ≥15 years under standard conditions; validated by ASTM B117 salt spray test.

- High precision: CNC-machined pulleys ensure less than 0.2mm groove runout, supporting high-speed, low-abrasion cable laying.

- Corrosion Resistance: Multi-layer protective coatings (galvanized and epoxy) pass 720h salt spray; suitable for coastal and chemical plant use.

- Load Capacity: Rated loads up to 360kg suitable for armored cables & high-tension tray installations. Yield safety margin >150% (per ANSI C135.1).

- Industry Certification: All series certified with ISO 9001:2015, and select grades meet FDA (food plant), CE (EU), and ROHS directives.

- Low Rolling Resistance: Bearings engineered for <0.1N coefficient; energy saving for electrical cable pulling equipment.

- Life Span: Fatigue tested for >750,000 cycles without visible wear or deformation (per internal and third-party labs).

- Customizable: Dimensions, groove type (V/U/Y), coating, and integrated bracket config available for OEMs and EPCs.

Cable Tray Pulley Product Benchmark vs. Market Standards

The radar visualization clearly indicates the Cable Tray Pulley from Bilopowtel excels in corrosion resistance, precision machining, and certification compliance, surpassing the market’s average performance benchmarks (source: user feedback, cabletrays.org standards).

Cable Tray Pulley Market Applications Analysis

Sector-wise adoption rate of Cable Tray Pulley. Highest usage in power distribution (30%) and petrochemicals (28%) reflects the increasing cable density and hazardous environment compliance needs (Ref: Electrical-Installation.org).

Custom Cable Tray Pulley Solutions

- OEM & ODM: Tailored groove shapes (V/U/Y), pulley diameter up to 400mm, customized material (stainless, reinforced nylon, brass-bushed).

- Integration: Engineering support for custom tray brackets, multi-axle sets for synchronized cable laying, and roller diameter precision (±0.1mm).

- Surface Choices: Select between hot-dip galvanized, nickel-chrome, or high-durability powder coatings for specific project corrosion or hygiene needs.

- Industry Focus: Solutions designed for high-humidity tunnels, marine yards, urban utility corridors, or hazardous areas requiring IECEx compliance.

- Testing Service: Pre-shipment sample validation: Load, rotation, salt-spray residency, & third-party (SGS/TÜV) certification available.

Application Case Study: Bilopowtel Cable Tray Pulley in Action

Project Overview: In 2023, a state petrochemical complex (China, Sinopec) upgraded its power cable infrastructure, requiring 1,200+ meters of fire-retardant tray cables routed through 2 km of chemical corridors.

Solution Adopted: Bilopowtel CTP-300S Cable Tray Pulley (304 SS, 300mm diameter, ANSI/ISO certified) with custom anti-spark surface was deployed.

- Installation Time Reduced: Cable laying speed improved by 37% vs. manual sliders (internal project record).

- Maintenance Savings: Projected annual labor cost cut: $16,700, due to zero groove deformation and 15-year rated service interval.

- Corrosion Performance: No visible oxidation after 730 hours simulated salt fog exposure (third-party: SGS report).

- Certification: All pulleys were delivered with ISO 9001, ANSI C135.1 load certificate, and traceable marking.

Service Life Test: Fatigue Endurance of Cable Tray Pulley (Dyno Results)

Certifications & Collaborations

- Manufacturing sites certified to ISO 9001:2015 and all pulleys produced per ANSI C135.1-2019 and ASTM A123 standards.

- Frequent supplier for Sinopec, State Grid (China), ABB (Asia), Delta Power, and numerous infrastructure EPCs globally.

- Products validated by SGS and TÜV; FDA-grade options available on request for cleanroom and food plant cable routing.

Delivery Lead Time & After-sales Service for Cable Tray Pulley

- Standard Models: 7-12 days ex-works lead time. Custom dimensions: 18-28 days, including prototype batch.

- Packing: Every Cable Tray Pulley is individually foam-packed in ISPM15-certified export carton. Full shipment traceability with digital certificates.

- Warranty: 24-month defect-free guarantee, 20,000 cycles minimum. Onsite failure analysis & free replacement for manufacturing defects.

- Support: 24/7 hotline and expert engineering consultancy (English/Chinese); remote video install support available.

Cable Tray Pulley: Professional FAQ

References & Further Reading

- Cable Tray Institute – Technical Standards & Guides

- MarketsandMarkets: Global Cable Tray Market Forecast 2027

- ASTM A123/A123M – Standard for Zinc (Hot-Dip Galvanized) Coatings

- Electrical Installation Wiki: Cable Tray Overview

- The Design and Selection of Cable Tray Systems (ResearchGate, Engineering Journal)

*Data visualizations powered by Chart.js. All referenced product technical data derived from manufacturer specifications, verified project records, and relevant international standards.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025