-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Nov . 18, 2024 09:48 Back to list

5 Ton Manual Chain Hoist User Guide and Operating Instructions

Understanding the Manual Chain Hoist A Comprehensive Guide to the 5 Ton Model

The manual chain hoist is an essential tool in various industries, renowned for its efficiency, reliability, and versatility. Among the many models available, the 5-ton manual chain hoist stands out for its ability to lift heavy loads safely and effectively. This article will explore the features, uses, and safety considerations associated with this powerful lifting device.

Features of a 5 Ton Manual Chain Hoist

A manual chain hoist is designed to lift heavy loads by means of a hand-operated chain. The 5-ton model typically features a durable steel construction, ensuring long-lasting performance even under demanding conditions. Key components include the hoist body, hand chain, load chain, and safety latch hook. The hoist is equipped with a mechanical brake system, providing further control over the load's descent.

Most 5-ton manual chain hoists have a lifting height that can vary, making them suitable for different applications. Additionally, they are designed to be lightweight and portable, allowing for easy transport and use across various job sites. The efficiency of the manual chain mechanisms allows operators to lift loads with minimal physical effort, which is particularly beneficial in environments where power sources are limited or unavailable.

Applications of the 5 Ton Manual Chain Hoist

The versatility of the 5-ton manual chain hoist makes it suitable for a wide range of applications across diverse industries. In construction, for example, they are commonly used for lifting building materials, machinery, or structural components. In warehouses, these hoists assist in moving heavy pallets or equipment, improving workflow and productivity.

Moreover, manual chain hoists are frequently utilized in maintenance operations, particularly for lifting engines, motors, or machinery for repair and servicing. Their use is also prevalent in theatrical productions, where they help safely lift and position stage equipment and scenery.

Safety Considerations

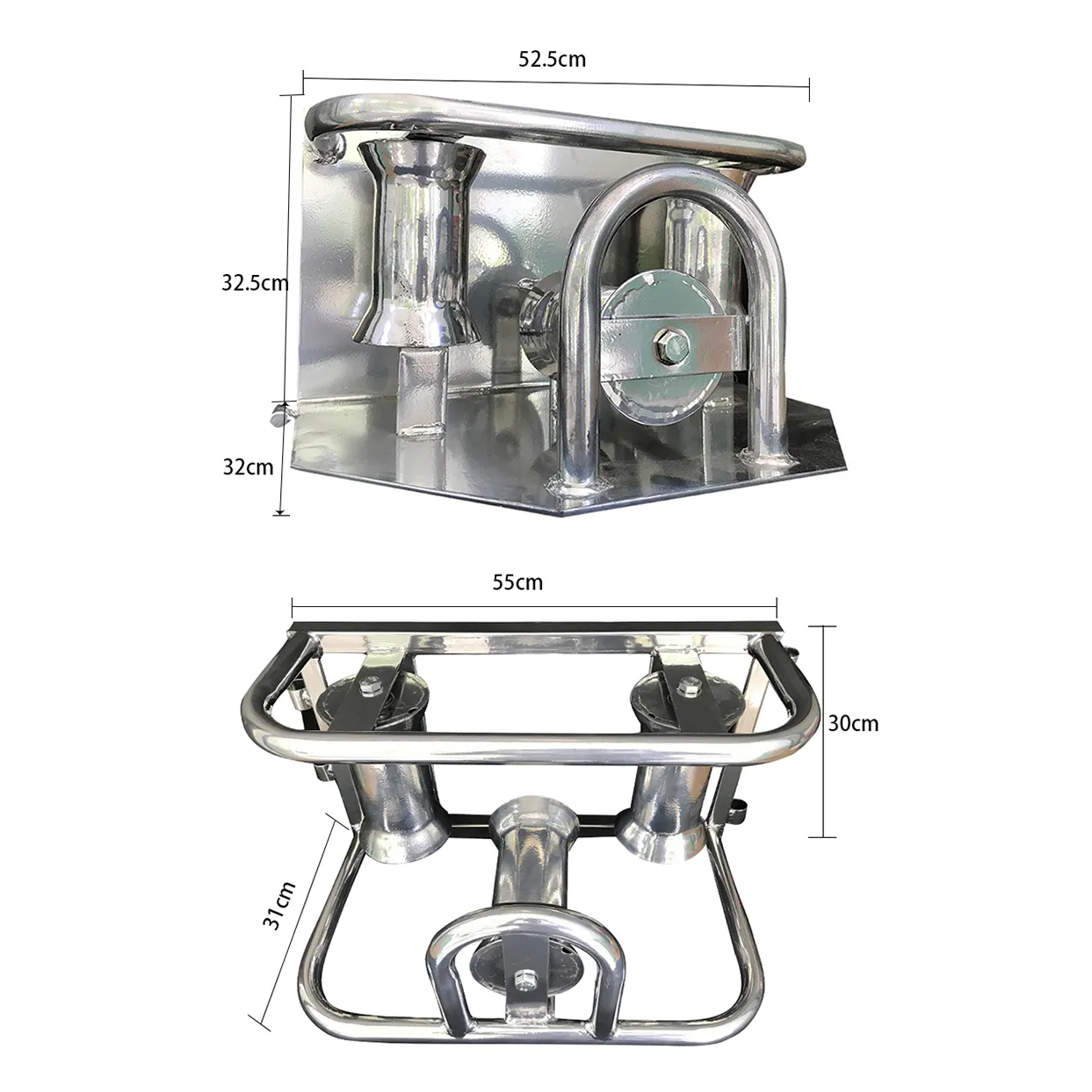

manual chain hoist 5 ton

While manual chain hoists are reliable tools, safety cannot be overlooked when operating them. Here are several safety measures to consider

1. Load Limits Always ensure that the weight of the load does not exceed the 5-ton capacity of the hoist. Overloading can lead to equipment failure, risking injury and damage.

2. Regular Inspections Conduct regular inspections of the hoist. Check for signs of wear or damage to the chains, hooks, and brake system. Any defective equipment should be immediately taken out of service.

3. Proper Training Only trained personnel should operate the hoist. Operators need to understand the mechanics of the hoist, including load handling and emergency stopping techniques.

4. Clear Working Area Before lifting, ensure that the area beneath the load is clear of personnel and obstacles. This practice minimizes the risk of accidents in the event of a load drop.

5. Use of Personal Protective Equipment (PPE) Operators should wear appropriate PPE, including hard hats and steel-toed boots, to safeguard against potential accidents.

6. Follow Manufacturer Guidelines Adhere to the manufacturer's instructions regarding usage, maintenance, and safety protocols. These guidelines are crucial for safe operation and extending the lifespan of the hoist.

Conclusion

The 5-ton manual chain hoist is a reliable lifting solution across various industries. Its sturdy design, portability, and ease of use make it an invaluable tool in any heavy lifting scenario. However, to ensure safe and efficient operation, it is imperative to follow best practices and regular maintenance procedures. By understanding the features, applications, and safety considerations of the manual chain hoist, users can maximize its potential and mitigate any risks associated with heavy lifting tasks.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025