-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jul . 20, 2024 13:04 Back to list

Innovative Ground Rod System for Enhanced Electrical Safety and Performance in Various Applications

Understanding Ground Rod Systems Importance and Implementation

Ground rod systems play a crucial role in electrical safety and system performance. These systems are designed to provide a reliable and low-resistance path for electrical faults, ensuring that excess electrical energy is directed safely into the ground. Understanding the significance and implementation of ground rod systems is essential for anyone involved in electrical work, whether in residential, commercial, or industrial contexts.

What is a Ground Rod System?

A ground rod system typically consists of one or more ground rods made of conductive materials, such as copper or galvanized steel. These rods are driven into the earth and connected to the electrical system of a building or structure. The primary purpose of the ground rod is to establish a stable reference point for the electrical system and to facilitate the dissipation of electrical energy, particularly during fault conditions, such as lightning strikes or equipment failures.

Why are Ground Rod Systems Important?

Safety is the foremost reason for implementing a ground rod system. In the event of a short circuit or a lightning strike, the excess electrical current needs a pathway to the earth to prevent damage to electrical equipment and reduce the risk of fire hazards. A well-designed ground rod system minimizes the chances of electric shock, protecting individuals and property from electrical hazards.

Moreover, ground rod systems contribute to the performance of electrical equipment

. Many devices, sensitive to voltage fluctuations, require a stable reference point to operate effectively. A properly grounded system helps in reducing noise and interference, thus enhancing the overall efficiency of electrical systems.Key Components of Ground Rod Systems

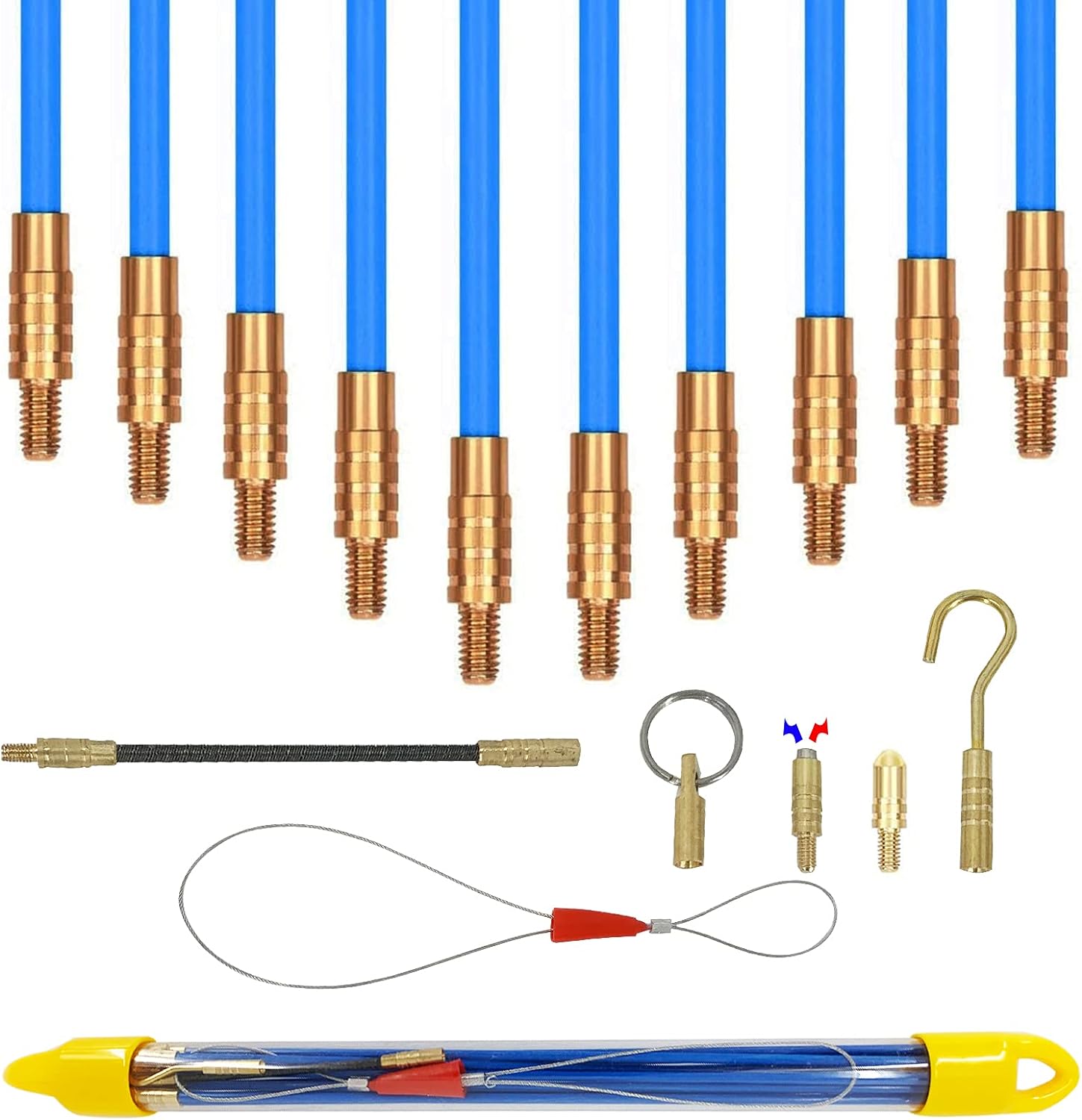

1. Ground Rods The rods are typically installed vertically and should be at least 8 feet long, with a minimum diameter of 5/8 inch. The material used should provide durability and excellent conductivity.

ground rod system

2. Connectors These components ensure a secure connection between the ground rod and the grounding wire. Various types of connectors are available depending on the rod material and service requirements.

3. Grounding Wire The wire connects the ground rods to the electrical panel and should be sized appropriately according to the National Electrical Code (NEC) guidelines.

4. System Configuration Depending on the specific requirements, ground rod systems may be installed as single rods or in a network configuration, which can include multiple rods interconnected to improve the overall grounding effectiveness.

Installation and Maintenance

Proper installation of a ground rod system is essential for its effectiveness. The depth of grounding rods should be sufficient to reach an area of moist soil, as the conductivity of the earth significantly affects the performance of the ground rods. It is also important to ensure that there are no corrosion inhibitors present that might impede conductivity.

Regular maintenance checks should be performed to ensure that the connections are secure and that there is no oxidation or corrosion of the rods and connectors. The performance of the system should be tested periodically to confirm that the grounding resistance remains within acceptable limits, typically below 25 ohms as per NEC standards.

Conclusion

In summary, ground rod systems are vital for ensuring the safety and efficacy of electrical systems. By providing a reliable path for dangerous electrical currents, these systems protect both people and property from potential hazards. Proper implementation and regular maintenance are essential to ensure that they function as intended. As we continue to rely on electrical systems in our daily lives, understanding and prioritizing grounding solutions will only become more critical.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025