-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

TEL:

0086-311-88862036

Jun . 13, 2024 11:04 Back to list

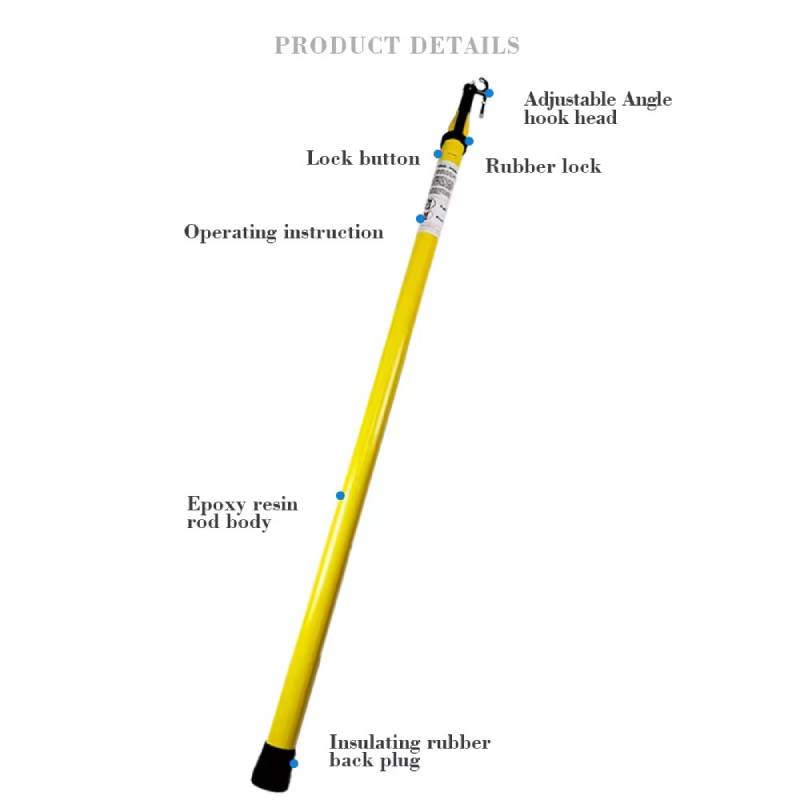

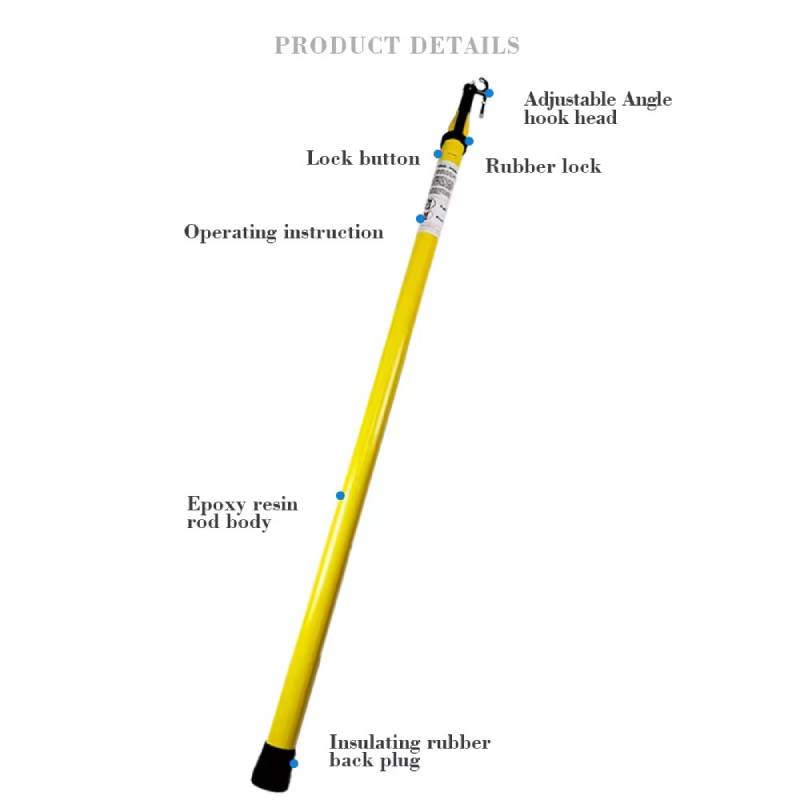

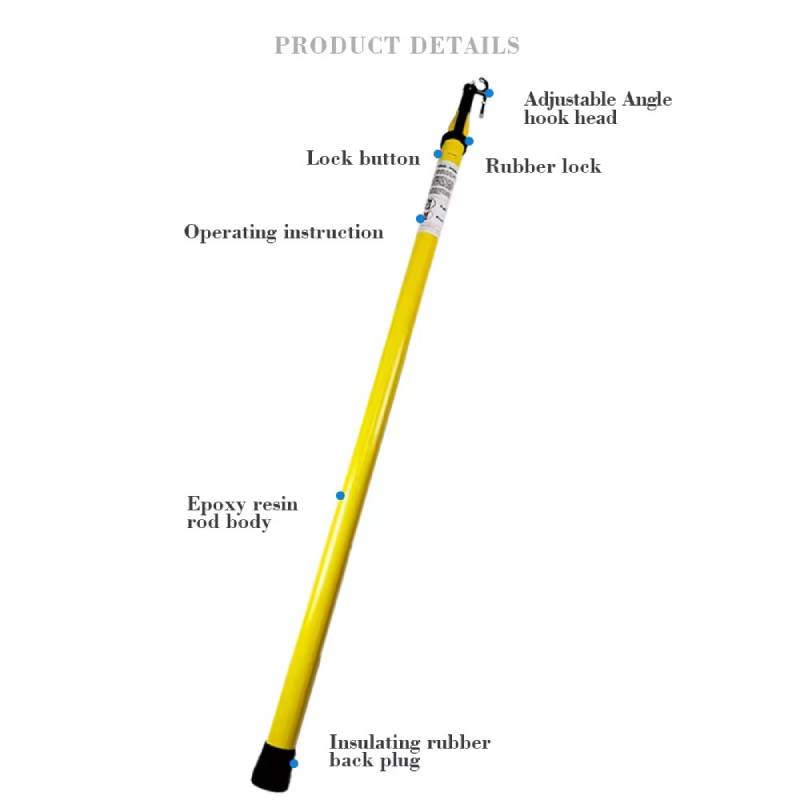

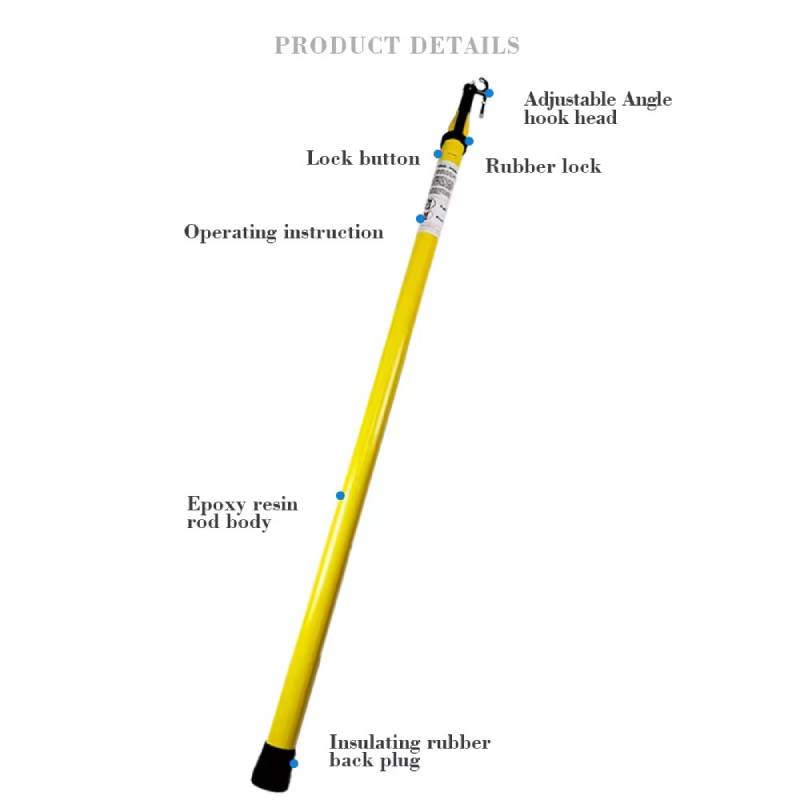

Hot stick for electrical work

The Importance of Hot Stick Tools in Electrical Work

Hot stick tools, an essential component of electrical utility operations, play a pivotal role in ensuring safety and efficiency during high-voltage tasks. These specialized tools, also known as insulating sticks or dead-end sticks, are primarily designed for working on energized electrical equipment, typically at voltages above 7200 volts. They serve as a non-conductive barrier between the worker and the live electrical circuit, significantly reducing the risk of electrocution.

The term hot stick comes from the fact that these tools are used on 'hot' or energized conductors. Made from high-quality composite materials or fiber glass, they possess excellent dielectric strength, which allows them to withstand high voltage without breaking down or conducting electricity. Their length varies depending on the voltage level and the distance required to safely perform the task, often extending up to several meters.

One of the key advantages of hot stick tools is their ability to extend the reach of the worker, enabling them to perform maintenance or repairs on overhead power lines without direct contact. This not only ensures the safety of the operator but also minimizes downtime and disruption to the electrical supply. Additionally, these tools come with various attachments like hooks, buckets, and clamps, allowing for a wide range of tasks to be executed.

Hot stick operations require a high level of skill and precision. Workers must undergo rigorous training to understand the proper usage, handling, and limitations of these tools Workers must undergo rigorous training to understand the proper usage, handling, and limitations of these tools Workers must undergo rigorous training to understand the proper usage, handling, and limitations of these tools Workers must undergo rigorous training to understand the proper usage, handling, and limitations of these tools

Workers must undergo rigorous training to understand the proper usage, handling, and limitations of these tools Workers must undergo rigorous training to understand the proper usage, handling, and limitations of these tools hot stick for electrical. They are taught to respect the 'live' environment and follow strict safety protocols, such as always maintaining a safe distance from grounded objects and ensuring the stick remains fully extended during operation.

In modern electrical infrastructure, hot stick tools have evolved alongside technological advancements. Some advanced models now incorporate features like built-in torque wrenches, temperature sensors, and even robotic arms, enhancing both safety and operational efficiency.

Despite the introduction of newer technologies, hot stick tools remain a mainstay in electrical work due to their reliability and effectiveness. As long as there are high-voltage electrical systems, the importance of hot stick tools will continue to be significant. They symbolize the commitment to safety in the face of potential danger, a testament to human ingenuity in safeguarding lives while keeping the lights on.

In conclusion, hot stick tools are more than just equipment; they are a lifeline for electrical workers operating in high-voltage environments. Their significance lies not only in their ability to perform complex tasks but also in their capacity to protect lives and maintain uninterrupted power supply. Understanding and utilizing these tools effectively is crucial in the ever-evolving landscape of electrical utilities.

hot stick for electrical. They are taught to respect the 'live' environment and follow strict safety protocols, such as always maintaining a safe distance from grounded objects and ensuring the stick remains fully extended during operation.

In modern electrical infrastructure, hot stick tools have evolved alongside technological advancements. Some advanced models now incorporate features like built-in torque wrenches, temperature sensors, and even robotic arms, enhancing both safety and operational efficiency.

Despite the introduction of newer technologies, hot stick tools remain a mainstay in electrical work due to their reliability and effectiveness. As long as there are high-voltage electrical systems, the importance of hot stick tools will continue to be significant. They symbolize the commitment to safety in the face of potential danger, a testament to human ingenuity in safeguarding lives while keeping the lights on.

In conclusion, hot stick tools are more than just equipment; they are a lifeline for electrical workers operating in high-voltage environments. Their significance lies not only in their ability to perform complex tasks but also in their capacity to protect lives and maintain uninterrupted power supply. Understanding and utilizing these tools effectively is crucial in the ever-evolving landscape of electrical utilities.

Workers must undergo rigorous training to understand the proper usage, handling, and limitations of these tools Workers must undergo rigorous training to understand the proper usage, handling, and limitations of these tools

Workers must undergo rigorous training to understand the proper usage, handling, and limitations of these tools Workers must undergo rigorous training to understand the proper usage, handling, and limitations of these tools hot stick for electrical. They are taught to respect the 'live' environment and follow strict safety protocols, such as always maintaining a safe distance from grounded objects and ensuring the stick remains fully extended during operation.

In modern electrical infrastructure, hot stick tools have evolved alongside technological advancements. Some advanced models now incorporate features like built-in torque wrenches, temperature sensors, and even robotic arms, enhancing both safety and operational efficiency.

Despite the introduction of newer technologies, hot stick tools remain a mainstay in electrical work due to their reliability and effectiveness. As long as there are high-voltage electrical systems, the importance of hot stick tools will continue to be significant. They symbolize the commitment to safety in the face of potential danger, a testament to human ingenuity in safeguarding lives while keeping the lights on.

In conclusion, hot stick tools are more than just equipment; they are a lifeline for electrical workers operating in high-voltage environments. Their significance lies not only in their ability to perform complex tasks but also in their capacity to protect lives and maintain uninterrupted power supply. Understanding and utilizing these tools effectively is crucial in the ever-evolving landscape of electrical utilities.

hot stick for electrical. They are taught to respect the 'live' environment and follow strict safety protocols, such as always maintaining a safe distance from grounded objects and ensuring the stick remains fully extended during operation.

In modern electrical infrastructure, hot stick tools have evolved alongside technological advancements. Some advanced models now incorporate features like built-in torque wrenches, temperature sensors, and even robotic arms, enhancing both safety and operational efficiency.

Despite the introduction of newer technologies, hot stick tools remain a mainstay in electrical work due to their reliability and effectiveness. As long as there are high-voltage electrical systems, the importance of hot stick tools will continue to be significant. They symbolize the commitment to safety in the face of potential danger, a testament to human ingenuity in safeguarding lives while keeping the lights on.

In conclusion, hot stick tools are more than just equipment; they are a lifeline for electrical workers operating in high-voltage environments. Their significance lies not only in their ability to perform complex tasks but also in their capacity to protect lives and maintain uninterrupted power supply. Understanding and utilizing these tools effectively is crucial in the ever-evolving landscape of electrical utilities. Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

BlLo lmport & Éxport is specialized in power and cable equipment andconsiruction tools,Qur main producis are FRP

duct rodder, cable rollerscable pulling winch, cable drum jack, cable pulling sock, etc.

Copyright © 2025 Shijiazhuang Bilo Import and Export Trading Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy