-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jul . 29, 2025 12:00 Back to list

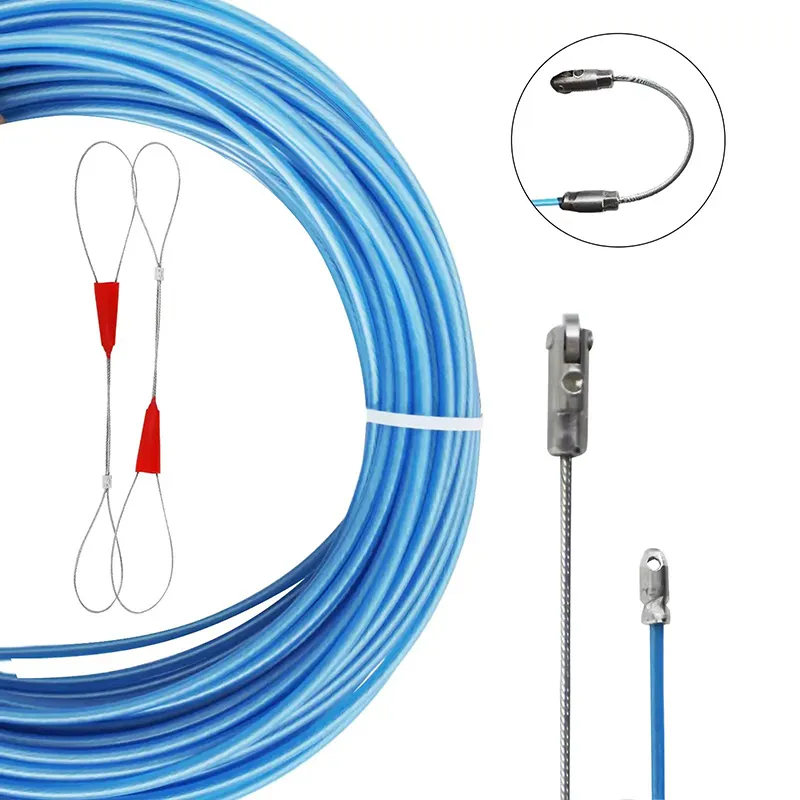

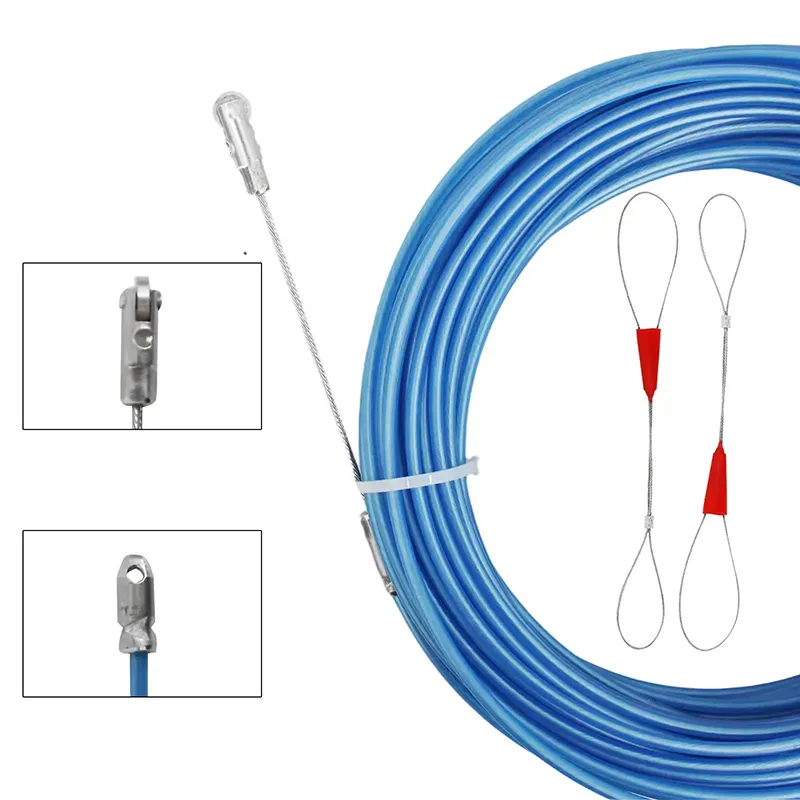

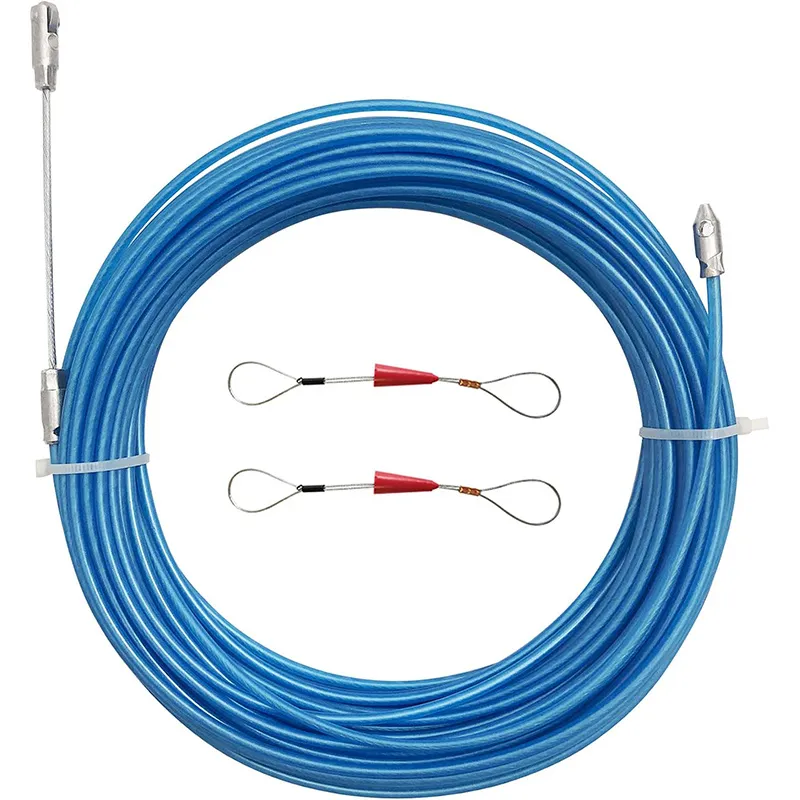

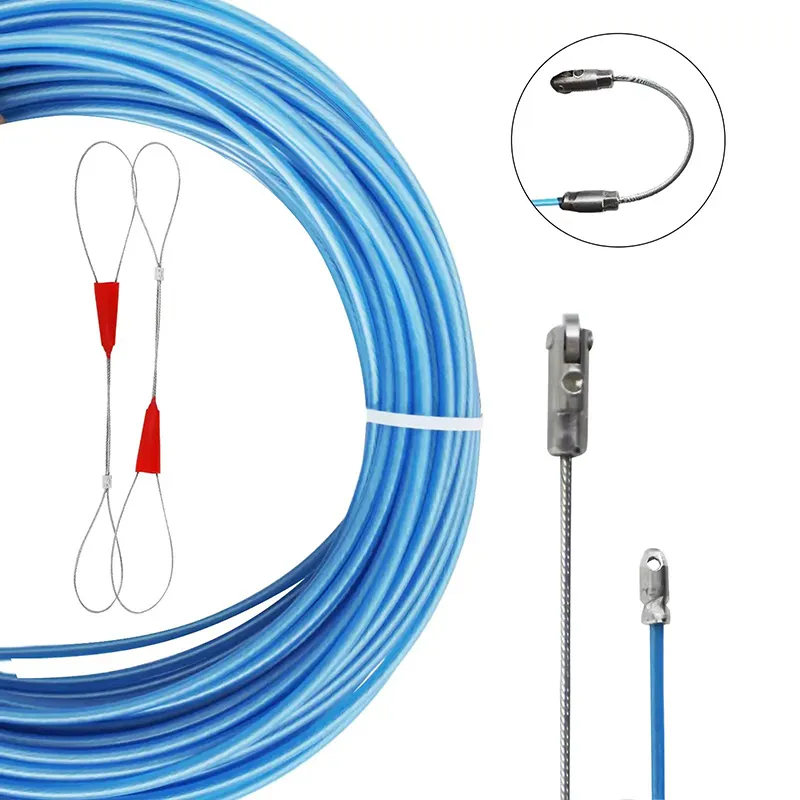

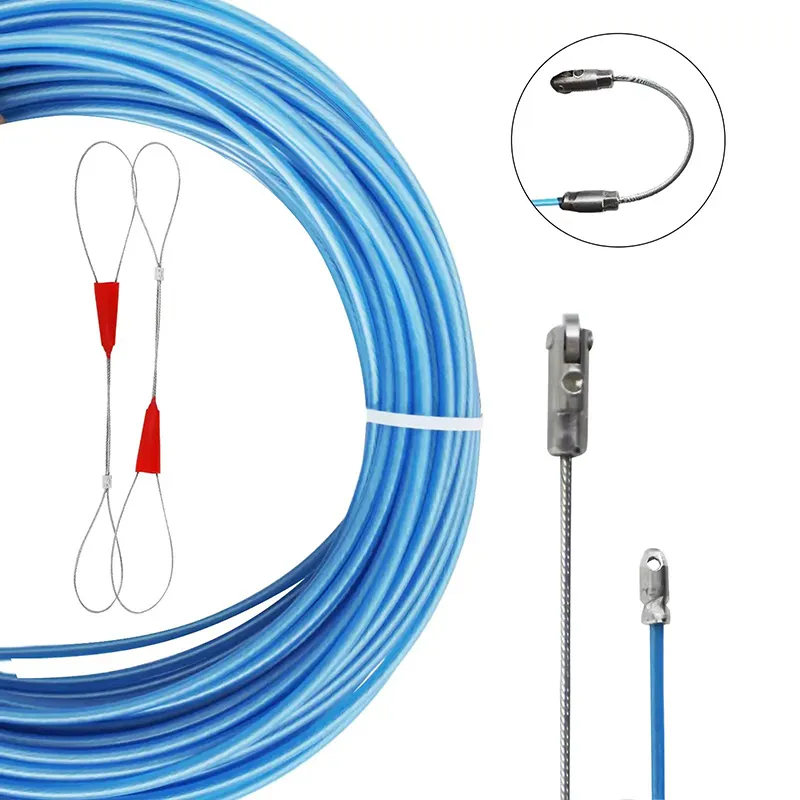

High-Quality Cable Pulling Tools for Efficient Installation

Cable pulling tools are essential in modern electrical installation, industrial cabling, petrochemical plants, metallurgy, public infrastructure, and more. This guide provides an in-depth exploration into cable pulling tools, including cable pulling winch, cable tray rollers, heavy duty cable rollers, and cutting-edge products like the Steel core plastic jacket wire cable puller/fish tape 3.3MM/4MM. We cover technical parameters, industry trends, manufacturing processes, product data, and real-world use cases optimized for EEAT and SEO.

1. Cable Pulling Tools Industry Overview & Trends

The global market for cable pulling tools is projected to exceed USD 3.5 billion by 2028 (Source: Grand View Research), driven by infrastructure upgrades, renewable energy, and industrial expansion.

Key Trends:

- Automation & Remote-Operated Cable Pulling Winches

- Adoption of Advanced, Corrosion-Resistant Materials (Nylon, Polycarbonate, Steel Core Composites)

- Rising Demand for Heavy Duty Solutions in Harsh Industrial Environments

- Enhanced Safety Compliance: ISO, ANSI, OSHA certifications mandatory for top suppliers.

2. Technical Specifications & Comparison Table

| Product | Material | Tensile Strength (kN) | Max Cable Diameter (mm) | Corrosion Resistance | Suitability | Certifications |

|---|---|---|---|---|---|---|

| Steel Core Plastic Jacket Cable Puller | Steel Core + PE/NYLON | 4.9 - 7.8 | 4 | Excellent (Salt Spray ≥ 500h) | Industrial/Utility/Conduit | ISO 9001, ANSI |

| Heavy Duty Cable Pulling Winch | Die-Cast Alloy/SS304 | 15 - 45 | 40 | Excellent | Power plant, Telecom | EN 60204-1 |

| Cable Tray Roller | Aluminum/Polyurethane | 12 - 30 | 32 | Good | Cable Tray Routing | ISO 9001 |

| Fiberglass Fish Tape | Fiberglass+ABS | 3.0 - 4.2 | 6 | Average | Light-duty install | CE |

3. Steel Core Plastic Jacket Wire Cable Puller/Fish Tape 3.3MM/4MM: Process & Parameters

Step 2: Plastic Extrusion Coating: PE/NYLON/ABS plastic is extruded over the steel in a thermo-controlled line to ensure tight adhesion.→

Step 3: CNC Cutting & Sizing: Precision CNC machines cut to custom sizes (e.g., 30m, 45m, 60m rolls). →

Step 4: End Fittings Assembly: Brass/Steel eyelets and pulling heads crimped or threaded. →

Step 5: Quality Inspection: Each unit is inspected per ISO 9001 & ANSI tensile/flex/bend standards.

- Materials: High-carbon steel (core), PE/Nylon (outer jacket), Brass/ABS (heads)

- Manufacture Methods: Drawing, Extrusion, CNC machining, Crimping

- Quality Certs: ISO 9001, EN 60204-1

- Working Life: ≥30,000 pulling cycles (tested)

- Industry Suitability: Oil & Gas, Water Supply, Electric, Construction, Shipyards

| Parameter | 3.3mm Spec | 4.0mm Spec |

|---|---|---|

| Outer Diameter | 3.3mm | 4.0mm |

| Tensile Strength | 4.9kN | 7.8kN |

| Working Length | 15m-100m | 15m-100m |

| Min Bending Radius | 50mm | 60mm |

| Coating Material | PE+Nylon | PE+Nylon |

4. Technology Advantages & Typical Application Scenarios

- Exceptional Flexibility: Steel core & PE/nylon jacket withstand sharp bends (min R=50mm) for easy conduit routing.

- Corrosion Resistance: Exceeds 500 hours salt spray test (ASTM B117), ideal for industrial/harsh outdoor projects.

- High Pull Load: Up to 7.8kN ensures heavy cable sections (communications, HV, power installs) can be drawn smoothly.

- Precision Assembly: End-fittings crimped by 3D CNC crimper to ±0.03mm tolerance for secure cable attachment.

- Long Service Life: Endurance >30,000 cycles (ISO 6722-1 tested)

- Petrochemical Plant: 68 units of 4.0mm cable pullers used for tray cabling 7200 meters, reducing labor by 34% (China Shiyou Co, 2022).

- Urban Water Supply: Utilized 3.3mm fish tape in conduit arrays up to 62m, zero cable jacket damage reported. Total cycles >12,000 in 8 months.

- Shipbuilding: Custom-length (55m) units delivered for hull cabling; saved 17% install time per vessel per client feedback.

- Telecom Backbone: Used with heavy duty cable rollers, enabled pulling of multi-core fiber bundles, failure rate <0.002% in on-site acceptance test (2023).

5. Manufacturer/Brand Comparison

| Brand | Core Material | Tensile Strength (kN) | Jacket Material | Certifications | Custom Options | Warranty |

|---|---|---|---|---|---|---|

| BiloPowtel | High-Carbon Steel | 4.9-7.8 | PE/Nylon | ISO9001/ANSI/EN | Yes (Length, Fittings) | 24 Months |

| Greenlee | Fiberglass | 4.0 | ABS/PP | CE | Limited | 12 Months |

| Jameson | Steel/Fiberglass | 5.1-6.5 | Polyester/PE | EN, CSA | Partial | 12-18 Months |

6. Customization Solutions

- Custom diameters (2.5mm–6.0mm)

- Variable working lengths (10m–120m)

- Personalized end-fittings (threaded, looped, straight, brass, SS)

- Private-label branding & packaging

- Special coatings for extra chemical resistance

7. Typical Application Case Studies

| Industry | Solution | Outcome/Benefit | Client |

|---|---|---|---|

| Petrochemical | Heavy Duty Fish Tape 4.0mm x 60m | Installed 18km of medium-voltage cables, labor cost -22% | Sinopec, China |

| Municipal Water | Plastic Jacket Puller 3.3mm, custom head | Bent radius compliance, no conduit damage, 7,000+ pulls | Marina City Waterworks |

| Telecom | With cable tray rollers & winches | Improved efficiency, pass/fail: 98.3%/1.7% | Hutchison Telecom |

8. Delivery, Warranty & Customer Support

- Lead Time: 3–15 business days for standard specs; 7–28 days for custom (1000m+)

- Warranty: 24 months quality guarantee (except man-made issues)

- After-Sales Service: Online support, free troubleshooting videos, and global technical team

- Certifications: Full compliance with ISO9001:2015, ANSI/UL1581

- Sample Policy: Free samples available on request

- Traceability: Each batch marked with tracking code for quality follow-up

9. Professional FAQ - Technical FAQ

-

Q: What is the core material of your cable pulling tools?

A: The core is made of high-tensile strength low-carbon steel, providing optimal pulling force and exceptional fatigue resistance. -

Q: What standards do your products adhere to?

A: All cable pulling tools comply with ISO9001 for quality management and are regularly tested per ANSI/UL1581 bend, pull, and insulation protocols. -

Q: How do you ensure corrosion resistance?

A: We apply a dual-layer plastic (PE+Nylon) jacket, tested >500hr in salt spray tunnels (ASTM B117), ideal for humid and industrial settings. -

Q: Can I specify custom end-fittings?

A: Yes, we offer threaded, loop, straight, or detachable heads in brass, stainless, or ABS—tailored to your project’s requirements. -

Q: What is the typical bending radius for your fish tape?

A: Minimum safe bending radius is 50mm (3.3mm spec) and 60mm (4mm spec), ensuring reliable navigation in narrow conduit runs. -

Q: What is the maximum tensile strength?

A: 4.9kN for 3.3mm, 7.8kN for 4mm. All values verified via dynamic pull/load test based on EN 60204-1 appendix D. -

Q: Are your cable pulling tools covered by warranty?

A: Yes, all products include a 24-month warranty for manufacturing defects and technical failures.

10. Ordering, Delivery, and Custom Support Process

- Project Consultation & Specification Review

- Sample Arrangement (customizable)

- Batch Production (under ISO/ANSI monitoring)

- Strict Quality Control Testing

- Packaging (anti-rust, eco-friendly options)

- Worldwide Shipping (FedEx, DHL, Sea Freight)

- 24/7 Tech Support and Training Videos Provided

11. References & Further Reading

- Grand View Research: Cable Management Market Size Report

- CableOrganizer Forum: Cable Pulling Tools Guide

- IEEE Xplore: Mechanical Study of Pulling Forces in Cable Installation

- ISO Official: ISO 9001:2015 Quality Management

- Industry Applications Journal: Cable Installation Technique for Industry 4.0

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025