-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Oct . 19, 2024 17:50 Back to list

grounding cable yellow green

Understanding Grounding Cables Focus on Yellow and Green Wires

Grounding cables play a critical role in ensuring the safety and reliability of electrical systems. Among the various types of wires used in grounding applications, yellow and green wires are particularly significant. This article will explore the importance of grounding cables, the specific roles of yellow and green wires, and their proper use in electrical systems.

The Importance of Grounding

Grounding is the process of connecting the electrical system to the earth, providing a safe path for electricity to follow in the event of a fault. This is essential to prevent electrical shocks, minimize the risk of fire, and protect equipment. Grounding systems work by directing stray electrical currents away from people and sensitive equipment, effectively bringing the electrical system to a zero potential state.

Most electrical codes and standards, including those published by the National Electrical Code (NEC) in the United States, mandate grounding for certain installations and equipment to enhance safety and performance.

The Role of Grounding Cables

Grounding cables are typically insulated wires that connect electrical equipment to a grounding rod or plate buried in the earth. These cables can vary in size and types, but they generally consist of copper or aluminum conductors. The primary function of grounding cables is to provide an effective route for electrical faults or static discharges to flow harmlessly into the ground.

In addition to protecting human life and equipment, a well-designed grounding system can reduce electrical noise and improve the overall performance of electronic devices, which is particularly important in sensitive installations like data centers and laboratories.

Yellow and Green Wires The Standard Color Codes

The specific use of yellow and green wires as grounding cables is essential for compliance with electrical codes and standards. In many regions, the National Electrical Code (NEC) or similar guidelines dictate that the green wire is to be used exclusively for grounding purposes, while the yellow wire may be used for various other functions, such as switch legs or control circuits.

grounding cable yellow green

1. Green Wire The green wire is universally recognized as the ground wire. It is crucial for connecting the metal frames of electrical devices to the earth. By eliminating any potential voltage that may build up on non-current-carrying parts, the green wire helps prevent dangerous electrical shocks. It's worth noting that the green wire should never be used for any other purpose other than grounding; doing so can create significant safety hazards.

2. Yellow Wire While yellow is not reserved for grounding, it is often used in specific applications, such as in control circuits or as a secondary phase conductor in certain low-voltage systems. In some cases, it may serve as a communication wire for alarm systems or control panels. Always check local wiring codes to ensure conformity when employing yellow wiring.

Proper Installation of Grounding Cables

To ensure the effectiveness of your grounding system, proper installation is paramount. The following considerations should be made when installing grounding cables

1. Wire Size Depending on the system's amperage, the size of the grounding wire may vary. The NEC suggests specific wire sizes based on different applications, so always consult local codes.

2. Connections Ensure tight and secure connections between the grounding wire and the equipment, grounding rod, or other conductive structures. Loose connections can result in arcing or the creation of resistive paths that may compromise safety.

3. Testing After installation, test the grounding system to confirm its effectiveness. Continuity tests, ground resistance tests, and visual inspections should be performed to ascertain that the grounding system is functioning correctly.

Conclusion

Grounding cables, particularly the yellow and green wires, are essential components of electrical safety systems. Understanding their specific uses and ensuring their proper installation can significantly mitigate electrical hazards. By adhering to the best practices and local regulations, equipment operators and electricians can create safer environments for themselves and others, promoting the longevity and reliability of electrical systems.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

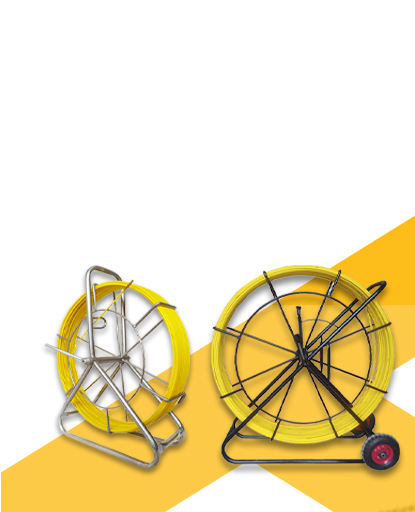

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025