-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jul . 27, 2024 11:04 Back to list

Exploring the Features and Benefits of 36 Inch Bolt Cutters for Heavy-Duty Tasks

The Importance of 36-Inch Bolt Cutters in Industrial Applications

When it comes to heavy-duty cutting tools, the 36-inch bolt cutter stands out as an essential piece of equipment in many industrial settings. Designed for strength and durability, these bolt cutters are engineered to handle tough materials like hardened steel locks, chains, and wires effortlessly. In this article, we will explore the features, benefits, and applications of 36-inch bolt cutters, highlighting why they are favored by professionals and DIY enthusiasts alike.

Features of 36-Inch Bolt Cutters

One of the most notable features of 36-inch bolt cutters is their long handle, which typically measures 36 inches in length. This design provides leverage, allowing users to exert significant force with minimal effort. The handles are often made from high-quality materials such as steel or fiberglass, enhancing both strength and durability. The blades are hardened for cutting through tough materials, and they come in different designs tailored to specific cutting tasks.

Additionally, many models are equipped with ergonomic grips to ensure comfort during prolonged use. Adjustable pivot points can also be found in some bolt cutters, enabling users to modify the cutting angle for improved performance. This versatility is vital for various cutting tasks and environments.

Benefits of Using 36-Inch Bolt Cutters

Using a 36-inch bolt cutter offers several advantages. First and foremost, the leverage provided by the long handles makes cutting easier and more efficient. This is especially beneficial in environments where heavy-duty cutting is required regularly. The increased cutting capacity means that users can tackle larger materials without needing multiple tools.

36 in bolt cutters

Moreover, the durability of these bolt cutters ensures a longer lifespan, making them a wise investment for industrial users. The ability to cut through materials like high-tensile wire, padlocks, and chains means that these tools are essential for construction companies, security industries, and maintenance crews.

Safety is another important aspect. Properly designed bolt cutters minimize the risk of injury compared to other cutting tools. The stable grip and controlled cutting action reduce the chances of slipping or miscutting, protecting the user and ensuring clean cuts.

Applications in Various Industries

The versatility of 36-inch bolt cutters allows for their application in various industries. In the construction sector, they are used for cutting rebar and metal rods, crucial for building strong structures. In the security field, professionals use them to cut through locks and chains in emergency situations.

Additionally, automotive and manufacturing sectors utilize bolt cutters for cutting cables and metal components during assembly or repair processes. Even in the landscaping industry, they are useful for cutting thick wire fencing or other harsh materials.

Conclusion

In summary, 36-inch bolt cutters play a vital role in a plethora of industrial applications. Their long handles provide the leverage needed to cut through tough materials effortlessly, while their durable construction ensures longevity and efficiency. With ergonomic designs and the capability to perform a wide range of cutting tasks, these tools are indispensable for professionals and DIY projects alike. As industries continue to evolve, the need for robust cutting tools will remain, solidifying the importance of 36-inch bolt cutters in the toolkit of tradespeople everywhere.

Latest news

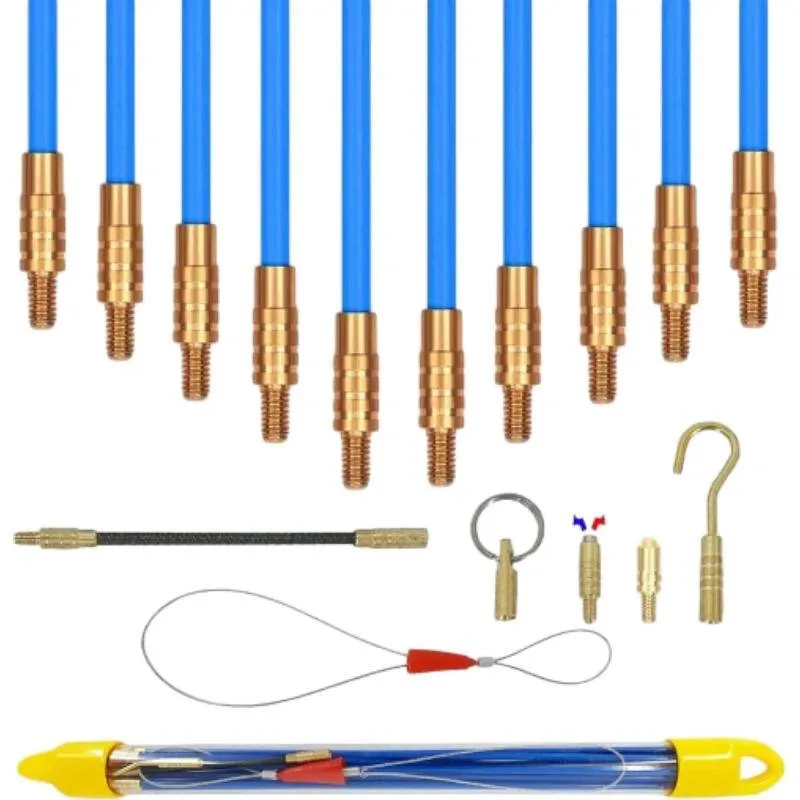

duct-rodders-and-conduit-rod-tools

NewsAug.22,2025

ratchet-pullers-and-wire-tightening-tools

NewsAug.22,2025

chain-ratchet-pullers-and-hoist-solutions

NewsAug.22,2025

telescopic-hot-stick-for-electrical-and-high-voltage-use

NewsAug.22,2025

cable-clamp-and-insulated-cable-clamp-systems

NewsAug.22,2025

duct-rodder-conduit-rodder-and-cable-solutions

NewsAug.22,2025