-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jul . 27, 2024 11:02 Back to list

Exploring the Best Practices for Securing Bonding Wires with Effective Clamp Solutions

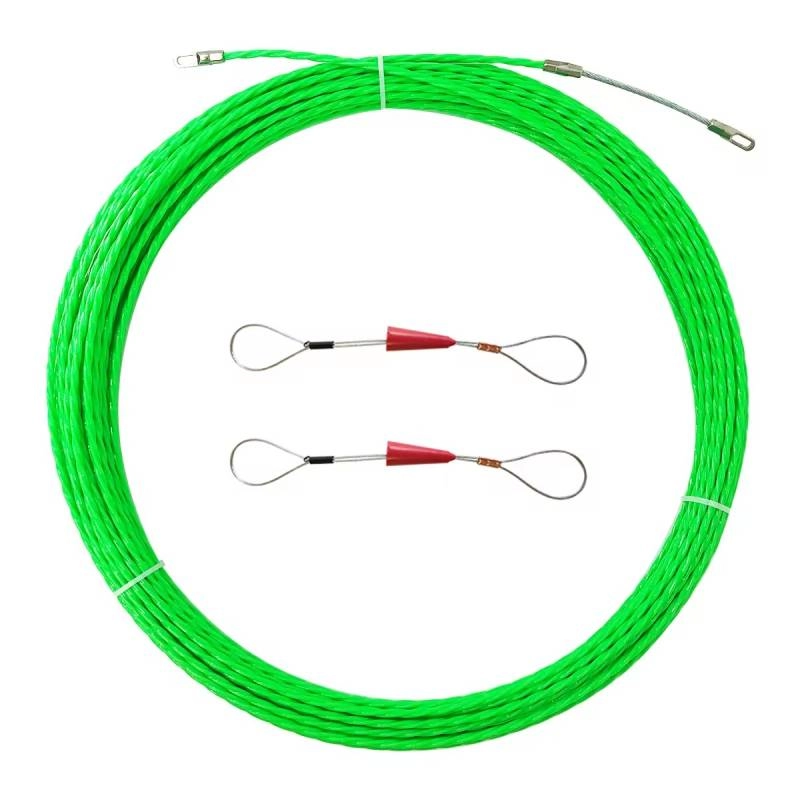

Understanding Bonding Wire Clamps Importance, Design, and Applications

Bonding wire clamps play a critical role in various electrical and electronic applications, particularly in ensuring the stability and reliability of connections in high-frequency and high-performance environments. These components are designed to secure bonding wires between different electronic parts, minimizing the risk of signal loss and improving overall device performance. In this article, we will explore the importance of bonding wire clamps, their design features, and their applications in modern technology.

Importance of Bonding Wire Clamps

At the core of every electronic device, especially those related to telecommunications and computing, is the need for reliable connections. Bonding wires are used to connect different semiconductor components, such as integrated circuits (ICs) and transistors, forming an essential part of the circuitry. A bonding wire clamp secures these wires, ensuring they remain connected under various conditions, including thermal expansion, mechanical stress, and vibration.

One of the key benefits of using bonding wire clamps is their ability to minimize parasitic inductance and capacitance. These parasitic effects can significantly degrade the performance of high-frequency circuits by introducing unwanted signals and noise. By ensuring a firm and stable connection, bonding wire clamps help maintain signal integrity, which is crucial in applications such as RF (radio frequency) communication, high-speed data transmission, and power distribution systems.

Design Features

Designing an effective bonding wire clamp involves several considerations that ensure the device can perform well in various conditions. Typically, bonding wire clamps are compact, allowing them to fit into the limited space available on circuit boards. Materials used in their construction must have suitable electrical and thermal conductivity while also being resistant to corrosion and wear.

A typical bonding wire clamp may feature a spring mechanism that provides continuous pressure, ensuring a secure grip on the bonding wire. The spring mechanism compensates for any movement or expansion due to temperature changes, which minimizes the risk of disconnection. Some advanced designs incorporate tools for easy installation and adjustment, allowing for greater flexibility during assembly.

bonding wire clamp

Additionally, the surface finish of bonding wire clamps is crucial. Smooth surfaces help reduce friction and wear on bonding wires, extending their operational life. Some clamps are also designed to accommodate various wire gauges, making them versatile for different applications.

Applications in Modern Technology

Bonding wire clamps are utilized in a wide array of industries, from consumer electronics to aerospace and automotive sectors. In telecommunications, for instance, bonding wire clamps are essential components in the manufacturing of smartphones, tablets, and other devices requiring high-frequency signal processing. They ensure that signals transmitted between different parts of a device remain unaffected by environmental interferences.

In power electronics, bonding wire clamps are used in the assembly of power modules, where they help secure connections that handle substantial electrical loads. Their reliability is paramount, as any disconnection or degradation in these connections can lead to significant system failures.

Moreover, the automotive industry increasingly relies on bonding wire clamps in electric and hybrid vehicles. With the growing complexity of vehicle electronics, secure and stable connections are necessary to ensure the safe and efficient operation of various systems, including battery management systems, motor control, and communication networks.

Conclusion

Bonding wire clamps, though often understated in the discussion of electronic components, are vital for ensuring connectivity and reliability in modern technology. As devices continue to evolve and become more sophisticated, the need for high-performance bonding wire clamps will only grow. Their design intricacies and applications highlight the importance of these components in achieving optimal performance across various industries. By understanding their significance, we can appreciate the crucial role they play in the functionality of our technologically driven world.

Latest news

What Are Construction Tools and How Are They Used?

NewsJul.11,2025

Professional-Grade Duct Rodding Tools for Superior Cable Installation

NewsJul.11,2025

Enhancing Safety and Efficiency with Modern Hot Stick Solutions

NewsJul.11,2025

Empowering Cable Installation with Advanced Rodder Solutions

NewsJul.11,2025

Elevate Your Cable Installation Projects with Cable Pulling Tools

NewsJul.11,2025

Efficient Cable Handling Solutions: Cable Rollers for Sale

NewsJul.11,2025