-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Aug . 14, 2024 12:19 Back to list

Essential Tools and Equipment for Linemen to Safely Handle Live Electrical Lines

Understanding Lineman Hot Stick Tools Essential Equipment for Electrical Safety

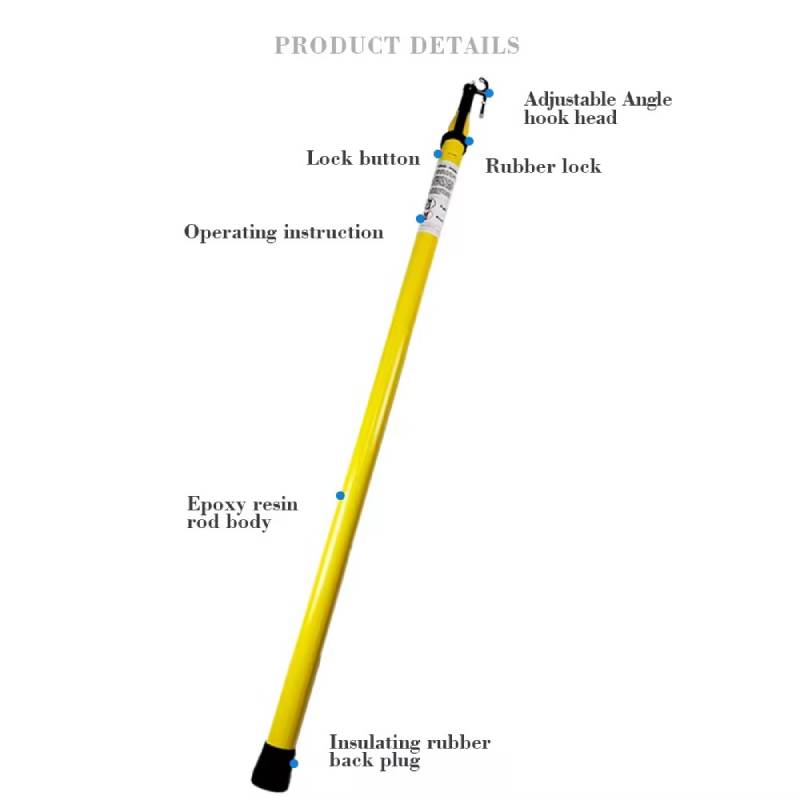

In the world of electrical utility maintenance, the safety of linemen is paramount. One of the most critical tools in maintaining this safety is the hot stick, also known as a live-line tool. Hot sticks are specifically designed to allow linemen to perform maintenance on energized lines while keeping a safe distance from live electrical conductors. Understanding the functionality, types, and importance of hot stick tools is essential for anyone involved in electrical work or utility management.

What Are Hot Sticks?

Hot sticks are insulated tools that provide a means for linemen to interact with high-voltage electrical equipment. They come in various types and lengths, made from materials such as fiberglass and composite polymers, which can withstand high voltage. The primary purpose of these tools is to facilitate the repair or maintenance of electrical lines without the lineman needing to physically contact live equipment.

Types of Hot Stick Tools

Hot sticks are versatile and come in several forms, each tailored for specific tasks

. Some common types include1. Standard Hot Stick This is the most common type, used for general maintenance tasks. It typically has a hook on the end for opening disconnect switches and a variety of attachments for different jobs.

2. Universal Hot Stick This tool features multiple accessories that can be adjusted or swapped out, making it useful for various applications.

3. Telescoping Hot Stick These sticks can be extended and retracted, providing flexibility and reach. Telescoping hot sticks are perfect for situations where access is restricted, allowing linemen to operate from a safe distance.

lineman hot stick tools

4. Insulated Pole Tool Similar to hot sticks, these tools are used to insert, remove, or adjust equipment from a distance, ensuring linemen remain safe from electric shock.

Importance of Hot Stick Tools

The primary advantage of using hot sticks lies in the protection they offer. Electric lines operate at incredibly high voltages, often exceeding 100 kV. Direct contact with such lines can result in severe injuries or fatalities. Hot sticks provide a safeguard by allowing linemen to perform necessary tasks from a safe distance, significantly reducing the risk of electrical shocks.

Additionally, hot sticks are essential for increasing efficiency in maintenance operations. With the ability to work on live lines, utilities can minimize outages and ensure a continuous supply of electricity. This capability is crucial, especially during peak usage times when outages can lead to widespread inconvenience for customers.

Maintenance and Safety Protocols

While hot sticks are designed for safety, proper maintenance and adherence to safety protocols are equally important. Linemen must regularly inspect and clean their hot sticks to ensure they are free from damage or contamination. Any signs of wear or damage must be addressed immediately, as compromised insulation can lead to electric shocks.

Furthermore, linemen must be trained in the correct use of these tools. This training typically includes understanding voltage ratings, learning how to properly maintain the equipment, and familiarizing themselves with emergency procedures. Regular drills and workshops can help reinforce the necessary skills and knowledge.

Conclusion

Lineman hot stick tools play a crucial role in maintaining the safety and efficiency of electrical utility work. Their design allows linemen to perform tasks on energized lines while minimizing the risk of injuries caused by electrical shocks. As technology continues to evolve, so too will the design and functionality of these essential tools, ensuring that linemen can safely and effectively meet the demands of modern electrical grids. Understanding the importance of hot sticks not only enhances operational safety but also underscores the dedication of utility professionals to protect both themselves and the communities they serve.

Latest news

Understanding Earth Wiring and Grounding: Essential Components for Electrical Safety

NewsAug.15,2025

The Ultimate Guide to Cable Pulling Tools and Equipment for Efficient Installations

NewsAug.15,2025

Streamline Your Projects with Advanced Cable Pulling Equipment

NewsAug.15,2025

Simplify Cable Installation with Advanced Cable Pulling Tools and Equipment

NewsAug.15,2025

Essential Guide to Link Sticks and Hot Sticks for Electrical Safety and Line Work

NewsAug.15,2025

Efficient Solutions for Cable Installation: Your Guide to Cable Pulling Winches and Equipment

NewsAug.15,2025