Aug . 21, 2025 20:20 Back to list

Efficient Cable Pulling Tools: Winches, Rollers & Tray Solutions

The Backbone of Modern Infrastructure: Mastering Cable Pulling Operations

In the vast landscape of modern infrastructure development, from urban construction to intricate industrial installations, the efficient and safe deployment of electrical cables and conduits is paramount. This critical task relies heavily on specialized equipment, primarily cable pulling tools. These tools are engineered to facilitate the precise and powerful installation of cables through complex pathways, ensuring reliability and minimizing operational downtime. Their significance spans across numerous sectors, including energy transmission, telecommunications, petrochemical facilities, and civil engineering projects, where robust and dependable cable infrastructure is indispensable.

The selection and application of appropriate cable pulling tools directly influence project efficiency, safety, and the longevity of the installed systems. As technology advances, these tools are evolving to offer greater power, precision, and automation, addressing the increasingly complex demands of contemporary infrastructure projects. Understanding the various types, their technical specifications, manufacturing processes, and optimal application scenarios is crucial for project managers, engineers, and procurement specialists aiming for operational excellence.

Deciphering Cable Pulling Tools: Types and Core Functions

The umbrella term cable pulling tools encompasses a diverse range of equipment, each designed for specific stages and challenges of cable installation. From manual operations for lighter cables to heavy-duty machinery for large power conduits, the right tool enhances safety and efficiency. Key categories include:

- Cable Pulling Winches: These are the workhorses of heavy-duty cable installations. A cable pulling winch utilizes a powerful motor (electric, hydraulic, or pneumatic) to apply significant tensile force, enabling the pulling of long, heavy cables through conduits, ducts, or open trenches. Modern winches often feature variable speed control, automatic tension monitoring, and data logging capabilities to prevent over-tensioning and ensure cable integrity.

- Cable Tray Rollers: Essential for guiding cables smoothly and reducing friction during horizontal or vertical pulls, cable tray rollers are deployed along the cable pathway. They typically feature robust wheels or rollers made from materials like aluminum, steel, or durable polymers, designed to withstand heavy loads and prevent damage to cable insulation.

- Heavy Duty Cable Rollers: As a specialized subset of cable rollers, heavy duty cable rollers are engineered for extremely large and heavy cables, often found in power transmission or industrial applications. They are constructed with reinforced frames and high-capacity bearings to manage significant weights and ensure frictionless movement, crucial for avoiding cable jacket abrasion or deformation.

- Cable Pulling Rollers: A broader category that includes various designs like corner rollers, straight line rollers, and specialized duct rollers. These tools are indispensable for navigating bends, inclines, and long straight runs, ensuring that the cable experiences minimal friction and stress throughout the pulling process. Proper placement of cable pulling rollers dramatically reduces the required pulling force and safeguards the cable.

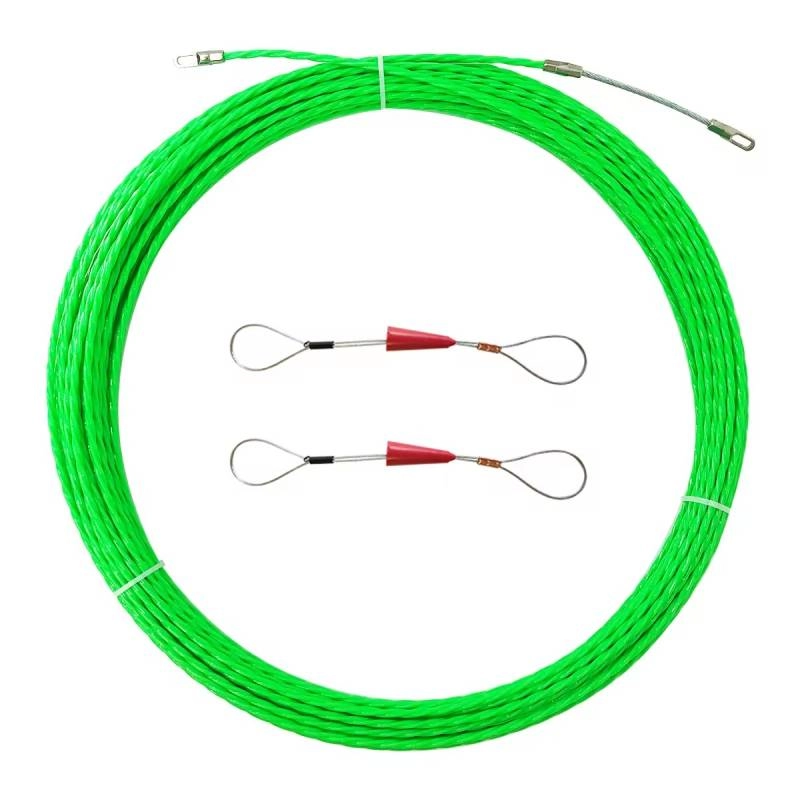

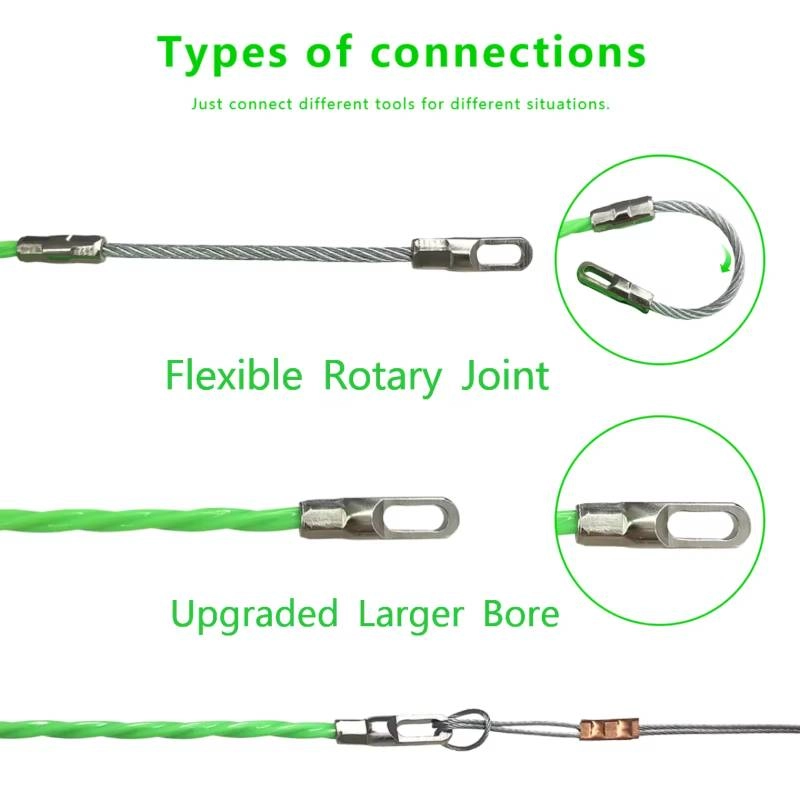

- Fish Tapes / Cable Pullers: For lighter-duty applications, particularly in residential, commercial, and light industrial settings, tools like fish tapes (also known as cable pullers) are used to pull wires or small cables through conduits or wall cavities. They are typically made of steel, fiberglass, or nylon, offering varying degrees of flexibility and rigidity.

The synergy between these tools is critical. For instance, a cable pulling winch is often used in conjunction with a series of cable tray rollers or heavy duty cable rollers to achieve a successful, damage-free cable installation over long distances or complex routes. Understanding their individual strengths and how they interact is foundational to effective project planning.

Industry Trends and Technological Advancements in Cable Pulling

The global market for cable pulling tools is experiencing dynamic growth, driven by massive investments in renewable energy infrastructure, expanding telecommunications networks (including 5G rollouts), and ongoing urbanization. Key trends shaping this industry include:

- Automation and Smart Systems: Integration of IoT, AI, and sensor technology into cable pulling winch systems is leading to smarter tools. These can monitor tension, speed, and distance in real-time, predict potential issues, and even adjust pulling parameters autonomously. This reduces human error and enhances safety.

- Enhanced Safety Features: Manufacturers are prioritizing operator safety with features like emergency stop buttons, overload protection, remote controls, and advanced braking systems. The focus is on minimizing risks associated with high-tension operations.

- Durability and Material Innovation: Demand for tools that can withstand harsh environments (extreme temperatures, corrosive substances) is driving the use of advanced alloys, composite materials, and specialized coatings. For example, heavy duty cable rollers now frequently incorporate self-lubricating bearings and anti-corrosion treatments.

- Portability and Modularity: There's a growing preference for modular, lightweight designs that are easier to transport and set up on diverse job sites. This is particularly relevant for urban projects with limited space.

- Sustainability: Energy-efficient motors and hydraulic systems are becoming standard, reducing power consumption and operational costs. Manufacturers are also exploring more sustainable materials and production processes.

According to market analyses, the global cable pulling tools market is projected to grow at a Compound Annual Growth Rate (CAGR) of approximately 5-7% from 2023 to 2030, driven by the expansion of smart grids, fiber optic networks, and the construction of new industrial complexes. This growth underscores the increasing sophistication and necessity of these tools in modern infrastructure projects.

The Manufacturing Journey: Crafting Precision Cable Pulling Tools

The production of high-quality cable pulling tools involves a meticulous multi-stage process, integrating advanced engineering with stringent quality control. This ensures each tool meets the rigorous demands of industrial use, offering superior performance, longevity, and safety. A typical manufacturing process for durable metallic components of these tools, such as the frames of heavy duty cable rollers or the drums of a cable pulling winch, would involve:

1. Material Selection and Sourcing:

The foundation of a robust tool lies in its materials. Common choices include high-grade alloy steels (e.g., 4140, 8620) for structural components due to their superior tensile strength and fatigue resistance, aluminum alloys for lightweight yet strong parts, and specialized polymers (e.g., UHMW-PE, Nylon 66) for rollers and wear plates to minimize friction and prevent cable damage. For components exposed to harsh environments, stainless steel or marine-grade aluminum is often chosen for its corrosion resistance. All raw materials are sourced from certified suppliers and undergo initial material verification tests.

2. Precision Manufacturing Processes:

- Cutting and Forming: Raw material sheets, bars, or tubes are precisely cut using advanced laser cutters or plasma cutters to ensure dimensional accuracy. Forming processes like bending, rolling, and stamping shape these materials into component forms.

- Casting/Forging: For parts requiring exceptional strength and intricate shapes, such as winch drums or specific roller assemblies, casting (e.g., investment casting for complex geometries) or forging (for maximum strength and grain refinement) processes are employed. Forging enhances the material’s structural integrity, making components like anchors or load-bearing shafts incredibly durable.

- CNC Machining: High-precision components are machined using Computer Numerical Control (CNC) equipment. This includes milling, turning, and drilling to achieve tight tolerances, critical for smoothly operating parts like axles, bearings seats, and complex gearing within a cable pulling winch. CNC ensures consistency and repeatability across batches.

- Welding: Structural elements are joined using advanced welding techniques (e.g., MIG, TIG welding) performed by certified welders. Post-weld inspection, including non-destructive testing (NDT) like ultrasonic or radiographic testing, ensures weld integrity and prevents structural failures.

- Heat Treatment: Many metal components undergo heat treatment processes such as hardening, tempering, or annealing to improve their mechanical properties, including hardness, toughness, and ductility. This is crucial for parts subjected to high stresses and wear.

3. Surface Treatment and Finishing:

To enhance durability, corrosion resistance, and aesthetic appeal, components undergo various surface treatments. These can include powder coating for weather resistance, galvanization for superior corrosion protection (especially for outdoor cable pulling rollers), anodizing for aluminum parts, or specialized industrial paints that resist abrasion and chemical exposure. These treatments extend the operational life, especially in demanding environments like petrochemical plants or marine applications.

4. Assembly and Integration:

Individual components are meticulously assembled into the final product. This stage includes the integration of mechanical parts, hydraulic systems, electrical wiring, and control panels. For complex systems like a cable pulling winch, this involves precision alignment of gears, motors, and monitoring sensors.

5. Rigorous Quality Control and Testing:

Quality assurance is embedded at every stage, culminating in comprehensive final product testing. This includes:

- Dimensional Accuracy: Verification against engineering drawings using CMM (Coordinate Measuring Machine) and other precision instruments.

- Material Verification: Spectroscopic analysis and mechanical property testing (tensile, hardness) of raw materials and finished parts.

- Load Testing: Each cable pulling tool, especially winches and heavy duty rollers, undergoes dynamic load testing to ensure it can safely operate at and beyond its rated capacity without compromise.

- Functional Testing: Comprehensive tests of all operational features, including speed control, braking systems, safety cut-offs, and data logging capabilities for winches. Rollers are tested for smooth rotation under load.

- Environmental Testing: For tools destined for harsh environments, tests for resistance to temperature extremes, humidity, dust, and corrosive agents are performed.

All products adhere strictly to international quality and safety standards such as ISO 9001 for quality management, ANSI standards for equipment safety, and CE marking for European market compliance. This rigorous process ensures a typical design life of 10-15 years, often more, for well-maintained equipment.

These manufacturing protocols ensure that the cable pulling tools deliver exceptional performance in critical applications. For instance, in petrochemical industries, tools require anti-corrosion properties and robust construction to handle volatile environments. In metallurgy, they must withstand high temperatures and heavy loads. For municipal water supply and drainage systems, resistance to damp conditions and ease of maneuverability are key. Our commitment to these processes results in tools that not only save energy through reduced friction but also offer superior resistance to corrosion and wear, translating into significant long-term operational savings.

Technical Parameters and Performance Metrics: A Detailed Overview

Selecting the correct cable pulling tools hinges on a thorough understanding of their technical specifications. These parameters define the tool's capabilities, suitability for specific tasks, and overall performance. Below is a detailed table outlining key parameters for various types of cable pulling tools, alongside typical values and their implications:

| Parameter | Cable Pulling Winch (Electric) | Heavy Duty Cable Roller | Fiberglass Fish Tape / Puller |

|---|---|---|---|

| Max. Pulling Force (kN/lbs) | 50 kN - 250 kN (11,000 - 55,000 lbs) | N/A (Designed for load support) | 2.5 kN - 5 kN (550 - 1100 lbs) |

| Max. Cable Diameter (mm/inch) | Up to 150 mm (6 inches) | Up to 200 mm (8 inches) | Up to 50 mm (2 inches) |

| Pulling Speed (m/min or ft/min) | Variable, 5-25 m/min (16-82 ft/min) | N/A | Manual (operator-dependent) |

| Power Source | Electric (380V/440V, 3-phase), Hydraulic, Diesel | N/A (Passive mechanical device) | Manual |

| Roller/Drum Material | Steel alloy (drum) | Alloy Steel, Aluminum, UHMW-PE | Fiberglass, Nylon, Steel |

| Weight (approx. kg/lbs) | 200 - 1500 kg (440 - 3300 lbs) | 5 - 30 kg (11 - 66 lbs) per unit | 0.5 - 5 kg (1 - 11 lbs) |

| Operating Temperature (°C/°F) | -20°C to +45°C (-4°F to +113°F) | -40°C to +60°C (-40°F to +140°F) | -10°C to +50°C (14°F to +122°F) |

| Safety Features | Auto shut-off, Overload protection, Emergency stop, Data logging | Anti-tip design, Smooth cable contact, High load rating | Non-conductive (fiberglass/nylon) |

| Typical Applications | Large power cables, telecom trunks, pipe pulling | Underground ducts, trenches, cable trays for heavy cables | Residential wiring, light commercial conduit runs |

| Certifications (Typical) | CE, ISO 9001, CSA, UL | CE, ISO 9001, ASTM | CE, RoHS, VDE |

Understanding these parameters allows engineers to precisely match the right cable pulling tools to project requirements, optimizing performance and safety. For instance, the maximum pulling force of a cable pulling winch must exceed the calculated friction and weight of the cable run, while the max cable diameter for cable tray rollers dictates their compatibility with specific cable sizes.

Key Advantages and Innovations: Driving Efficiency and Safety

Modern cable pulling tools are not merely mechanical aids; they are sophisticated engineering solutions designed to overcome the inherent challenges of cable installation. Their advanced features translate into significant operational advantages:

- Enhanced Safety Protocols: Contemporary cable pulling winch systems incorporate intelligent tension control, automatically adjusting pulling force to remain within safe limits, thus preventing cable damage from overstretching. Emergency stop features and remote-control options further minimize direct operator exposure to high-tension areas.

- Significant Energy Efficiency: The design of components like cable pulling rollers and heavy duty cable rollers focuses on reducing friction to an absolute minimum. This allows for lower pulling forces, which in turn reduces the energy consumption of the pulling winch. High-efficiency motors in winches further contribute to reduced power usage and lower operational costs.

- Unparalleled Durability and Longevity: Built from robust, often treated materials (e.g., galvanized steel, advanced polymers), these tools are designed to withstand abrasive environments, heavy loads, and prolonged use. This ensures a longer service life, reducing the frequency of replacements and associated capital expenditure.

- Precision and Control: Advanced control systems in winches offer precise speed and tension management, critical for sensitive cables like fiber optics. The smooth operation provided by well-designed cable tray rollers ensures uniform cable tension distribution, preventing kinks and jacket damage.

- Versatility and Adaptability: Many cable pulling tools are modular and adaptable, capable of being reconfigured for different cable sizes, conduit types, and pulling scenarios (e.g., horizontal, vertical, underground). This versatility maximizes equipment utilization across various projects.

- Reduced Manpower and Time Savings: By automating and streamlining the pulling process, these tools significantly reduce the manual labor required and accelerate project completion times. A single cable pulling winch, managed by a small team, can accomplish what would otherwise require a large crew and much longer hours, leading to substantial labor cost savings.

These innovations not only improve operational metrics but also contribute to a safer, more sustainable construction environment. The reduction in cable damage through precise control, for example, leads to fewer material losses and less waste, aligning with modern ecological and economic objectives.

Application Scenarios Across Diverse Industries

The utility of cable pulling tools extends across virtually every sector involved in infrastructure and industrial operations. Their adaptability makes them indispensable in a wide array of demanding environments:

- Energy Sector (Power Transmission & Distribution): Critical for installing high-voltage transmission lines, underground power cables, and cables within substations. Heavy duty cable rollers and powerful cable pulling winches are essential for handling the immense weight and stiffness of these large conductors over long distances, ensuring the structural integrity of the cable remains intact.

- Telecommunications Industry: With the rapid deployment of fiber optic networks and 5G infrastructure, delicate fiber cables need to be pulled through conduits without exceeding their minimal pulling tension limits. Specialized cable pulling tools with precise tension control are vital to prevent damage to these sensitive lines.

- Construction and Civil Engineering: From pulling electrical wiring in commercial buildings to installing service cables in tunnels and bridges, cable pulling rollers and fish tapes are ubiquitous. They facilitate efficient cable routing through complex architectural designs and challenging urban environments.

- Petrochemical and Oil & Gas: In these hazardous environments, tools must be robust and often explosion-proof. Cable pulling tools are used to install control cables, power lines, and instrumentation cables in refineries, offshore platforms, and pipelines. Their anti-corrosion properties and durable construction are paramount for safety and longevity.

- Mining Industry: Underground mining operations require durable and reliable cable pulling tools to install heavy-duty power cables and communication lines in confined and often wet conditions. The ability of tools to operate in challenging, abrasive environments is critical.

- Water Treatment and Wastewater Management: Installing electrical and control cables for pumps, valves, and filtration systems in water treatment plants and sewage facilities often involves damp, corrosive environments. Tools with superior corrosion resistance and sealed bearings are highly valued.

- Manufacturing and Industrial Plants: For laying out new production lines or upgrading existing ones, cable pulling tools help in efficiently installing power cables for heavy machinery and data cables for automation systems within factory floors and industrial complexes.

In each of these scenarios, the selection of the right cable pulling tools directly impacts project timelines, labor costs, and most importantly, the safety and reliability of the installed infrastructure. Our tools are designed to excel in these varied and demanding applications, ensuring consistent performance.

Manufacturer Comparison and Selection Guide

Choosing the right manufacturer for cable pulling tools is a strategic decision that affects project outcomes, long-term costs, and operational reliability. While specific brand comparisons are beyond this scope, we can outline critical factors and illustrate them with a general comparison table of hypothetical manufacturers based on their typical offerings.

Key Factors for Manufacturer Selection:

- Product Range and Specialization: Does the manufacturer offer a full suite of cable pulling tools, from a powerful cable pulling winch to diverse cable pulling rollers and fish tapes? Or do they specialize in a niche, like heavy-duty equipment?

- Quality and Certifications: Adherence to international standards (ISO, CE, ASTM) signifies a commitment to quality and safety. Look for companies with robust quality control processes and relevant product certifications.

- Technological Innovation: Are they investing in R&D? Do their tools incorporate modern features like intelligent tension control, remote operation, or advanced material science?

- Customization Capabilities: Can they provide tailored solutions for unique project requirements, such as specific dimensions for cable tray rollers or specialized winch configurations?

- After-Sales Support and Warranty: Comprehensive warranty, readily available spare parts, and responsive technical support are crucial for minimizing downtime.

- Industry Reputation and Experience: Longevity in the market and positive client testimonials reflect reliability and proven performance.

- Pricing and Total Cost of Ownership (TCO): While initial price is a factor, consider the TCO, which includes maintenance, energy consumption, and expected lifespan.

| Criteria | Manufacturer A (Premium) | Manufacturer B (Balanced) | Manufacturer C (Economy) |

|---|---|---|---|

| Product Range | Comprehensive, specialized Heavy-Duty Cable Pulling Winches, diverse Rollers. | Broad range covering most standard needs, good selection of Cable Pulling Rollers. | Basic range, focus on standard Cable Pulling Tools like Fish Tapes. |

| Quality & Certifications | Exceeds ISO, CE, ASTM. Strict internal QA. Robust testing. | Meets ISO, CE standards. Reliable quality control. | Meets basic safety standards. Quality can vary. |

| Technological Adv. | Leading innovator: IoT integration, AI tension control, advanced materials. | Incorporates latest proven tech: digital displays, good safety features. | Standard mechanical designs, basic functionalities. |

| Customization | Highly flexible, strong engineering team for bespoke solutions. | Limited customization on select products. | Very little to no customization offered. |

| After-Sales Support | Global network, comprehensive training, rapid parts, long warranties. | Regional support, standard warranty, reasonable parts availability. | Basic support, shorter warranty, limited parts inventory. |

| Price Point | Premium (High initial investment, low TCO) | Mid-range (Balanced initial cost and TCO) | Economy (Low initial investment, higher TCO due to maintenance/replacement) |

When evaluating manufacturers of cable pulling tools, it's essential to look beyond the immediate purchase price. A higher initial investment in a quality manufacturer often yields significant long-term savings through reduced maintenance, extended product life, increased efficiency, and enhanced safety, ultimately contributing to a lower Total Cost of Ownership (TCO).

Customized Solutions for Unique Challenges

While standard cable pulling tools meet a broad spectrum of needs, certain projects present unique challenges that necessitate bespoke solutions. These could involve:

- Extreme Environments: For projects in arctic temperatures, desert heat, or highly corrosive marine environments, standard materials and lubricants may not suffice. Custom tools might incorporate specialized alloys, cryogenic-grade lubricants, or enhanced protective coatings for cable pulling rollers.

- Unusual Cable Sizes or Weights: When dealing with exceptionally large diameter power cables or particularly delicate fiber optic bundles that exceed standard capacities, manufacturers can engineer custom heavy duty cable rollers and cable pulling winch systems with tailored load capacities and precise tension control mechanisms.

- Confined Spaces or Complex Routes: Urban utility tunnels or industrial plants with dense existing infrastructure often require compact cable pulling tools or specialized rollers with unique geometries to navigate tight turns and limited access points. This might involve custom-designed modular rollers that can be assembled on-site.

- Specific Safety or Regulatory Requirements: Certain industries or regions may have unique safety protocols or certifications. Custom solutions can integrate additional safety features, specialized monitoring systems, or materials that comply with specific fire retardancy or explosion-proof standards.

- Integration with Existing Systems: For large-scale infrastructure projects, new cable pulling tools might need to seamlessly integrate with existing pulling systems, data logging platforms, or specialized transport vehicles.

Our engineering team specializes in understanding these unique project demands. By collaborating closely with clients from conceptualization to deployment, we design and manufacture customized cable pulling tools that perfectly match the operational context. This often involves detailed CAD modeling, finite element analysis (FEA) for stress testing, and prototyping to ensure the customized solution delivers optimal performance and safety in its intended environment. This expertise in tailoring solutions is a critical differentiator, ensuring that even the most complex cable installation challenges can be met efficiently and safely.

Real-World Application Cases: Delivering Results

The practical impact of advanced cable pulling tools is best demonstrated through real-world applications where they have overcome significant challenges and contributed to project success. Here are illustrative examples:

Case Study 1: High-Voltage Transmission Line Installation (Energy Sector)

Challenge: Installing 132kV power cables across a mountainous terrain with steep inclines and sharp bends over a distance of 5 km. The cables were heavy (approx. 15 kg/meter) and delicate, requiring precise tension control to prevent damage. Traditional methods were slow and presented high safety risks.

Solution: A high-capacity cable pulling winch with integrated tension monitoring and data logging was deployed. This was complemented by a series of custom-designed heavy duty cable rollers that could handle severe angles and distribute cable weight evenly, reducing localized stress points. These rollers featured robust, impact-resistant polyurethane wheels and sealed bearings, ideal for the harsh outdoor conditions.

Outcome: The project completion time was reduced by 30% compared to initial estimates. The precise control offered by the winch prevented any cable jacket damage, and the use of specialized rollers minimized friction, leading to a 20% reduction in required pulling force, thereby saving energy. The overall safety record for the project was exemplary, with zero tension-related incidents.

Case Study 2: Urban Fiber Optic Network Expansion (Telecommunications)

Challenge: Deploying hundreds of kilometers of fiber optic cables through congested underground conduit networks in a bustling metropolitan area. The challenge was exacerbated by numerous existing utility lines, tight bends, and the extreme fragility of fiber optic cables, which have very low permissible pulling tension.

Solution: Lightweight, flexible fiberglass fish tapes (cable pullers) were used for initial pilot line threading, followed by specialized blowing equipment (air-assisted cable pullers) in conjunction with miniature, anti-abrasion cable pulling rollers designed for small diameter conduits. The rollers were placed at every bend and long straight section to ensure minimal contact friction.

Outcome: The efficient use of appropriate cable pulling tools facilitated rapid deployment without damaging the sensitive fiber. The minimal friction rollers ensured the delicate cables were protected throughout the complex pulls. This led to a 40% improvement in installation speed for conduit sections and a significant reduction in material waste due to damaged cables, proving the value of purpose-built tools for sensitive applications.

These cases exemplify how investing in the right cable pulling tools not only ensures operational success but also delivers substantial returns in terms of efficiency, cost savings, and safety, solidifying our position as a trusted partner in demanding infrastructure projects.

Ensuring Reliability: Quality, Support, and Warranty

For B2B buyers, particularly in capital-intensive industries, the decision to invest in cable pulling tools extends far beyond the initial purchase price. It encompasses the assurance of long-term reliability, robust after-sales support, and comprehensive warranty coverage. These elements collectively contribute to the trustworthiness and total value proposition of a supplier.

- Uncompromising Quality Assurance: Our commitment to quality is foundational. All cable pulling tools, including our heavy duty cable rollers and cable pulling winches, are manufactured under strict ISO 9001:2015 certified quality management systems. Each component undergoes rigorous testing, from raw material inspection to final functional and load testing. This adherence to global standards (e.g., CE, ANSI, ASTM) ensures that our products not only meet but often exceed industry benchmarks for performance and safety. Our products are engineered for a minimum service life of 10 years under normal operating conditions, a testament to their durable construction and superior materials.

- Robust Warranty Commitment: We stand behind the durability and performance of our cable pulling tools with a comprehensive 2-year warranty on all manufacturing defects and operational failures under normal use. This commitment provides our clients with peace of mind and safeguards their investment. Extended warranty options and service agreements are also available for critical infrastructure projects, providing an added layer of protection and scheduled maintenance.

- Dedicated Customer Support: Our support infrastructure is designed to be highly responsive and knowledgeable. A team of experienced technical professionals is available to provide pre-sales consultation, assist with product selection, and offer post-sales troubleshooting. This includes guidance on optimal usage, maintenance best practices, and resolving any operational queries. We offer multi-channel support including phone, email, and dedicated online portals.

- Efficient Spare Parts and Service Network: Minimizing downtime is crucial for large-scale projects. We maintain a comprehensive inventory of genuine spare parts for all our cable pulling tools, ensuring rapid availability. Our global network of certified service partners and technicians ensures that professional support, maintenance, and repairs are readily accessible, regardless of project location. For instance, common wear parts for cable tray rollers or essential components for a cable pulling winch can be dispatched within 48 hours for urgent requirements.

- Training and Technical Documentation: To maximize the efficiency and safety of our tools, we provide detailed operational manuals and offer on-site or virtual training programs for client teams. This ensures proper understanding of equipment capabilities, maintenance routines, and safety protocols, extending the lifespan of the tools and enhancing operational safety.

Our enduring partnerships with leading construction companies, energy providers, and telecommunication giants globally underscore our reputation as a trusted provider of high-performance cable pulling tools. This trust is built on a foundation of consistent quality, reliable support, and a commitment to customer success that extends far beyond the initial sale.

Frequently Asked Questions (FAQ)

- Q1: What is the primary difference between a cable pulling winch and a cable puller / fish tape?

- A1: A cable pulling winch is a heavy-duty motorized machine used for pulling large, heavy cables over long distances, often hundreds or thousands of meters, with significant pulling force (tens of kilonewtons). It's typically used for power transmission cables, large communication lines, or industrial conduits. A cable puller / fish tape, on the other hand, is a manual, flexible tool designed for lighter duty applications, primarily for pulling wires or small cables through conduits, walls, or ceiling spaces in residential, commercial, or light industrial settings. It applies much less force and is ideal for shorter runs.

- Q2: How do cable tray rollers contribute to the efficiency and safety of cable pulling operations?

- A2: Cable tray rollers are essential for reducing friction during cable pulls, especially over long distances or through complex pathways with turns and changes in elevation. By elevating the cable off the ground or the bottom of the trench/tray and providing smooth rolling surfaces, they minimize abrasion, prevent kinking, and significantly reduce the required pulling force. This not only makes the pull easier and faster but also safeguards the cable's outer jacket and internal conductors from damage, extending its lifespan and improving safety for the installation crew.

- Q3: What critical factors should be considered when selecting heavy duty cable rollers?

- A3: When selecting heavy duty cable rollers, consider the maximum cable diameter and weight they must support, the environment (e.g., corrosive, abrasive, extreme temperatures), the type of path (straight, corner, trench, duct), and the material of the rollers themselves (e.g., steel for extreme loads, aluminum for lighter weight, UHMW-PE for delicate cables). Ensure they have robust frames, sealed bearings for smooth operation, and an appropriate load rating to prevent structural failure or cable damage during heavy pulls.

- Q4: What is the typical delivery timeframe for custom cable pulling tools?

- A4: The delivery timeframe for custom cable pulling tools can vary significantly based on the complexity of the design, material availability, and manufacturing queue. Generally, after the design and engineering phase (which can take 2-4 weeks), manufacturing and testing can require an additional 8-16 weeks. We provide detailed project timelines with clear milestones at the outset of any custom order, ensuring transparency and adherence to schedules for our clients.

- Q5: How does your company ensure the long-term reliability and support for your cable pulling tools?

- A5: We ensure long-term reliability through our adherence to ISO 9001 quality standards, rigorous testing protocols (including load and functional tests), and the use of high-grade materials for extended product life. Our commitment extends to comprehensive after-sales support, including a 2-year warranty, readily available genuine spare parts inventory, and a global network of technical support and service partners. We also offer training and detailed documentation to empower clients to maintain and operate our cable pulling tools effectively, maximizing their operational lifespan.

Conclusion: Powering Progress with Precision and Reliability

The demand for robust, efficient, and safe cable pulling tools is escalating, driven by global infrastructure expansion and technological advancements. From the powerful capabilities of a cable pulling winch to the indispensable friction reduction provided by heavy duty cable rollers and cable tray rollers, these tools are pivotal in ensuring the seamless deployment of critical cable infrastructure across diverse industries.

Our dedication to engineering excellence, meticulous manufacturing processes, and adherence to the highest international quality standards (ISO, ANSI) ensures that every product, whether a specialized cable pulling roller or a versatile Cable Puller / Fish Tape, delivers unparalleled performance, safety, and longevity. We understand the complex requirements of B2B projects in sectors like petrochemical, metallurgy, and utilities, and our solutions are tailored to meet these demanding challenges, contributing to energy efficiency, corrosion resistance, and overall project success.

By providing comprehensive technical insights, real-world application examples, and a strong commitment to after-sales support and warranty, we empower our clients to make informed decisions. Partner with us for your next infrastructure project, and experience the difference that superior cable pulling tools and dedicated expertise can make in achieving operational efficiency, safety, and long-term reliability.

References

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality management systems – Requirements.

- American National Standards Institute (ANSI). (Various). ANSI Standards for Construction and Demolition Operations.

- Institution of Engineering and Technology (IET). (2019). Wiring Regulations (BS 7671).

- ASTM International. (Various). Standards for Metals and Mechanical Testing.

- Market Analysis Reports on Global Cable Pulling Equipment Market. (Various market research firms, e.g., Grand View Research, MarketsandMarkets).

Latest news

Hydraulic Crimping Tool – Precision & Heavy-Duty Speed

NewsNov.05,2025

Cable Pulling Swivel | High-Strength, Anti-Twist, Stainless

NewsNov.04,2025

Cable Pulling Tools – Pro-Grade, Safe, Fast Install

NewsNov.03,2025

Hydraulic Crimping Tool – Fast, Precise, Quick-Change Dies

NewsNov.02,2025

Hydraulic Crimping Tool for Sale | Fast, Precise, Heavy-Duty

NewsNov.01,2025

Duct Rodder for Sale – Non-Conductive, Durable Fiberglass

NewsOct.31,2025